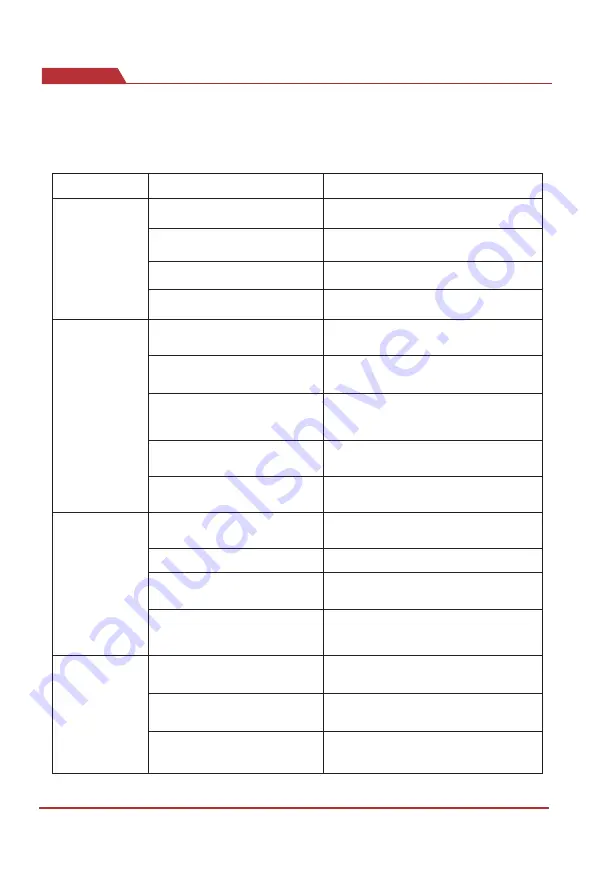

13

YZ-X7

Troublting

Stopic

Reason

Solutions

Machine

Not

Working

Battery dead battery

Battery charging

Battery fault

Replacement of the battery

Battery wiring is loose

Tighten the battery wiring

Main fuse burning off

Replace the fuse

Brush

plate

motor

not

working

Brush head goes up from the

ground

Lower the brush head

Battery battery meter locked

not started

Battery charging

Brush disc motor circuit breaker

triggers power

jump

Reset the brush circuit circuit

breaker button

Brush (top / down) switch

fault

Please Contact the Service

Center

Motor carbon brush wear

Please Contact the Service

Center

Vacuum

motor

not

operativ

e

Water absorption off the

ground

Lower water absorption

Vacuum motor fuse burning off

Replace the fuse

Vacuum motor or wiring failure

Please Contact the Service

Center

Motor carbon brush wear

Please Contact the Service

Center

Small or

watery

outflow

Block of clear water box filter or

solution pipe

Clean the clear water tank

filter

Flow control knob flow speed

setting is too low

0 Adjust the water flow

control knob

Unscrew of the control-making

knob

Lubricate knob rear lock screw