SINGLE-CYLINDER ENGINES

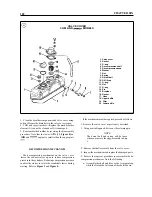

ing it out with an appropriate size drift or

4. Coat the inside diameter of the plug bore and the outer

pin punch. When removing a large core

diameter of the new plug with sealer. Use an oil-resistant

plug, the use of a universal impact slide

sealer if the plug is to be installed in an oil gallery or a

hammer is recommended.

ter-resistant sealer for plugs installed in the water jacket.

5.

Install the new core plug with an appropriate size core

plug installation tool

(Figure

driver or socket. The

3. Clean the plug bore thoroughly to remove all traces of

outside edge of the plug should be 2-3 mm (0.08-0.12 in.)

the old sealer. Inspect the bore for any damage that might

inside the block.

interfere with proper sealing of the new plug.

6. Repeat Steps 1-5 to replace each remaining core plug.

Table

1 ENGINE SPECIFICATIONS (1

1

Bore

75

(2.95

in.)

Stroke

72

(2.83

in.)

Displacement

cc

(19.4

cu. in.)

Number of cylinders

1

Cylinder bore diameter

75.000-75.030

(2.9528-2.9540

in.)

Bore out-of-round-max.

0.02

mm

(0.0008

in.)

Cylinder block

0.07

(0.0028

in.)

Piston diameter

Standard

74.910-74.940

(2.9492-2.9504

in.)

Wear limit

74.850

mm max.

(2.9468

in.)

Piston top clearance

0.68-0.88

mm

(0.027-0.035

in.)

Piston ring side clearance

Top ring

0.065-0.100

(0.0026-0.0039

in.)

Second ring

0.035-0.070

mm

(0.001 4-0.0028

in.)

Oil ring

0.020-0.055

mm

(0.0008-0.0022

in.)

Ring end gap (all rings)

0.20-0.40

mm

(0.008-0.016

in.)

Piston pin diameter

19.991 -20.000

mm

(0.7870-0.7874

in.)

Piston pin hole diameter

In piston

19.995-20.008

mm

(0.7872-0.7877

in.)

In rod

20.000

mm

(0.7874

in.)

Piston pin clearance

In rod

0.025-0.047

mm

9

in.)

In piston

0.005

tight-0.017 mm loose

(0.0002 in. tight-0.0007

in. loose)

Piston ring width

Top

second ring

1.97-1.99

mm

(0.0776-0.0783

in.)

Oil control ring

3.97-3.99

mm

(0.1563-0.1571

in.)

Crankshaft main

Timing gear end

43.950-43.964

mm

(1.7303-1.7309

in.)

Flywheel end

mm

(2.3602-2.3608

in.)

Journal out-of-round-max.

0.01

(0.0004

in.)

Crankshaft end play

0.06-0.19

(0.0024-0.0075

in.)

Crankshaft runout-max.

0.1 5

mm

(0.006

in.)

Main bearing clearance

Timing gear end

0.036-0.092

(0.0014-0.0036

in.)

Flywheel end

0.036-0.095

(0.0014-0.0037

in.)

Crankshaft thrust

Front

2.75

mm

(0.108

in.)

Inner

2.25

mm

(0.089

in.)

diameter

39.950-39.964

in.)

Journal out-of-round-max.

0.01

(0.0004

in.)

bearing clearance

0.028-0.086

mm

(0.001 1-0.0034

in.)

Connecting rod side clearance

0.2-0.4

mm

(0.008-0.016

in.)

Cylinder head

0.07

mm

(0.003

in.)

Summary of Contents for 1GM10

Page 1: ...YANMAR DIESEL INBOARD SHOP MANUAL ONE TWO 8 THREE CYLINDER ENGINES...

Page 6: ......

Page 7: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ...GENERAL INFORMATION 21 Bearing Blocks Press Shaft arm Bearing Spacer Press k 4 bed...

Page 36: ...30 CHAPTER TWO CHARGING SYSTEM TYPICAL Battery switch...

Page 39: ......

Page 44: ...38 CHAPTER TWO LUBRICATION SYSTEM 2GM AND 2GM20 MODELS...

Page 46: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 55: ......

Page 57: ......

Page 58: ......

Page 64: ......

Page 66: ......

Page 70: ......

Page 71: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 112: ...106 CHAPTER SIX...

Page 114: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 145: ...FUEL INJECTION AND GOVERNOR SYSTEMS 139 FUEL INJECTION SYSTEM Fuel tank hose fuel pipe...

Page 148: ......

Page 149: ......

Page 150: ......

Page 151: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 165: ......

Page 170: ...164 CHAPTER EIGHT CLOSED COOLING SYSTEM TYPICAL rnlxlng elbow Joint...

Page 172: ......

Page 174: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 184: ......

Page 190: ......

Page 196: ......

Page 197: ......

Page 201: ......

Page 202: ......

Page 204: ......

Page 205: ......

Page 208: ......

Page 209: ......

Page 219: ......

Page 224: ...218 CHAPTER ELEVEN...

Page 231: ......

Page 235: ......