110

CHAPTER SIX

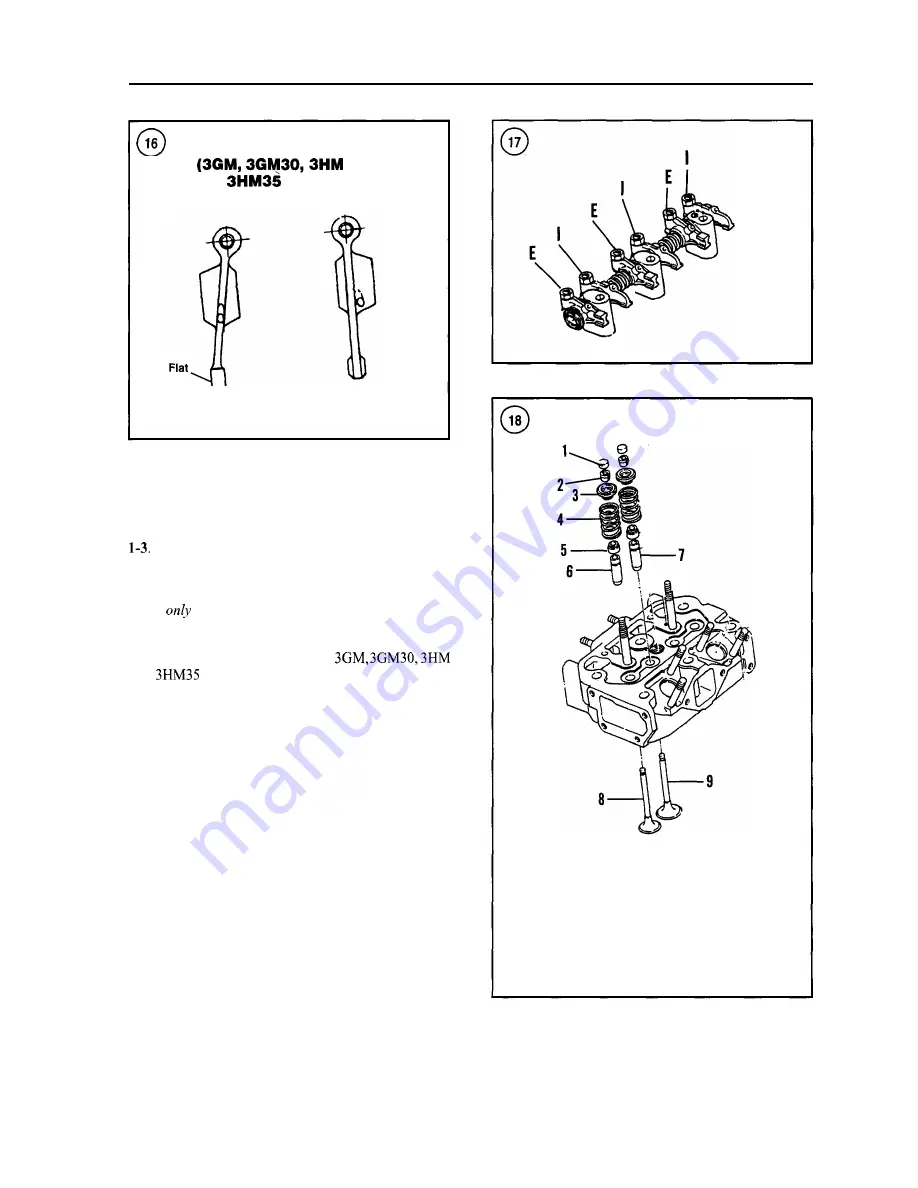

ROCKER ARMS

AND

MODELS

U

INTAKE

EXHAUST

6. Inspect and measure the inside diameter of the rocker

arm bushing and the outside diameter of the rocker arm

shaft. Replace the rocker arm or rocker arm shaft if the

measurements exceed the specifications listed in Tables

NOTE

The

rocker arm and bushing are available

as a unit.

7. Reassemble and reinstall the rocker arm assembly by

reversing the removal procedure. On

and

engines, identify the intake and exhaust

valves as shown in Figure 16, then position them on the

shaft in the order shown in Figure

17.

8. Adjust the valve clearance as described in Chapter

Three.

VALVES AND VALVE SEATS

Servicing the valves, guides and valve seats must be

done by a dealer or machine shop, as special knowledge

and expensive machine tools are required.

A

general practice among those who do their own ser-

vice is to remove the cylinder head, perform all disassem-

bly except valve removal and take the head to a dealer or

machine shop for inspection and service. Since the cost is

low relative to the required effort and equipment, this is

usually the best approach, even for experienced mechan-

ics. The following procedures are provided to acquaint the

home mechanic with the procedure.

VALVE COMPONENTS

1.

Wear cap

2.

Keys

3.

Valve spring retainer

4.

Valve spring

5.

Valve seal

6.

Exhaust valve guide

7.

Intake valve guide

8.

Exhaust valve

9.

Intake valve

Summary of Contents for 1GM10

Page 1: ...YANMAR DIESEL INBOARD SHOP MANUAL ONE TWO 8 THREE CYLINDER ENGINES...

Page 6: ......

Page 7: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ...GENERAL INFORMATION 21 Bearing Blocks Press Shaft arm Bearing Spacer Press k 4 bed...

Page 36: ...30 CHAPTER TWO CHARGING SYSTEM TYPICAL Battery switch...

Page 39: ......

Page 44: ...38 CHAPTER TWO LUBRICATION SYSTEM 2GM AND 2GM20 MODELS...

Page 46: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 55: ......

Page 57: ......

Page 58: ......

Page 64: ......

Page 66: ......

Page 70: ......

Page 71: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 112: ...106 CHAPTER SIX...

Page 114: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 145: ...FUEL INJECTION AND GOVERNOR SYSTEMS 139 FUEL INJECTION SYSTEM Fuel tank hose fuel pipe...

Page 148: ......

Page 149: ......

Page 150: ......

Page 151: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 165: ......

Page 170: ...164 CHAPTER EIGHT CLOSED COOLING SYSTEM TYPICAL rnlxlng elbow Joint...

Page 172: ......

Page 174: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 184: ......

Page 190: ......

Page 196: ......

Page 197: ......

Page 201: ......

Page 202: ......

Page 204: ......

Page 205: ......

Page 208: ......

Page 209: ......

Page 219: ......

Page 224: ...218 CHAPTER ELEVEN...

Page 231: ......

Page 235: ......