222

CHAPTER

ELEVEN

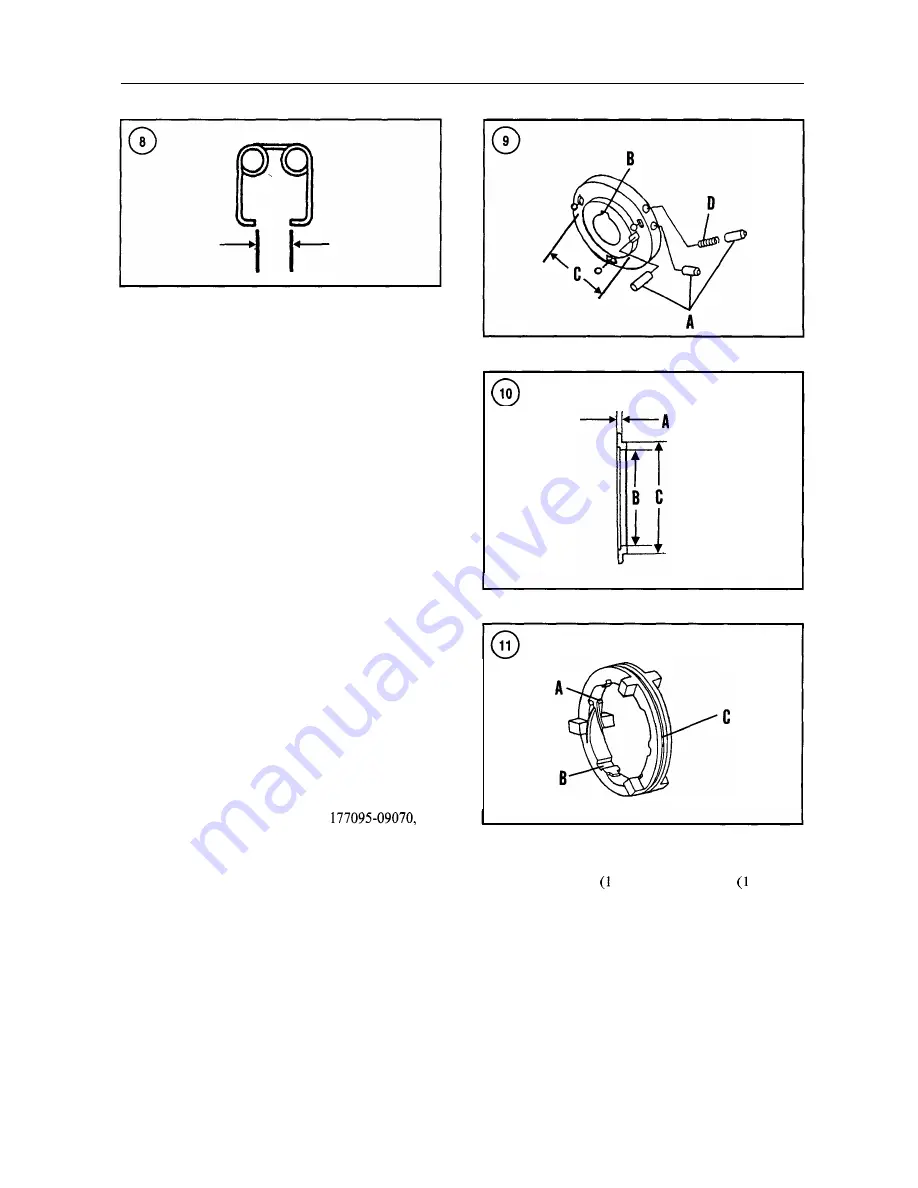

16. Measure the return spring end gap (Figure

8) and

compare the result with the specification in Table 3.

17. Check the driving plate ball grooves (Figure 9),

detent pin bores, detent pins (A) and keyway (B) for any

noticeable wear.

18. Measure the driving plate hub outer diameter (C, Fig-

ure 9) and compare it with the specification in Table 3.

19. Measure detent pin spring

(D, Figure 9) free length

and compare it with the specification in Table 3.

20. Measure the plate spring retainer thickness (A, Fig-

ure 10) and compare the result with the specification in

Table 3. Measure the plate spring inside diameter (B) and

compare with the specification in Table

3. Measure the

plate spring shoulder diameter (C) and compare the result

with the specification in Table 3.

2 1. Measure the free width of the Belleville springs and

compare it with the specification in Table 3.

22. Inspect the shift ring pressure grooves (A, Figure 11)

and pin contact grooves (B) for any signs of excessive

wear. Measure the width of the circumferential groove (C)

and compare the result with the specification in Table 3.

Reassembly

1. Install the Belleville springs on the forward gear so the

concave sides face each other as shown in Figure 12. Po-

sition the retainer (12, Figure 3) over the Belleville

springs and slide the snap ring onto the spline of the for-

ward gear. Using Yanmar special tool

or a

suitable equivalent tool, compress the forward gear as-

sembly in a vise and engage the snap ring in the groove

around the forward gear splines.

2. Refer to Step 1 and assemble the reverse gear,

Belleville springs, retainer and snap ring.

3.

To determine the correct thickness of shims (16 and 26,

Figure 3), install the inner bearing race and spacer in their

respective gears. Measure the depth (A, Figure 13) of the

bearing race from the end of the gear as shown in Figure

13. Install shims equal to the depth.

4. Alternately install four friction plates (14, Figure 3)

and three steel plates 5) on the forward gear 0) splines

starting with a friction plate.

5. Refer to Step 4 and assemble the reverse gear, steel

plates and friction plates.

6 .

Using a suitable bearing driver, install the output shaft

front bearing onto the shaft. Be sure the bearing inner race

contacts the collar on the end of the output shaft.

Summary of Contents for 1GM10

Page 1: ...YANMAR DIESEL INBOARD SHOP MANUAL ONE TWO 8 THREE CYLINDER ENGINES...

Page 6: ......

Page 7: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ...GENERAL INFORMATION 21 Bearing Blocks Press Shaft arm Bearing Spacer Press k 4 bed...

Page 36: ...30 CHAPTER TWO CHARGING SYSTEM TYPICAL Battery switch...

Page 39: ......

Page 44: ...38 CHAPTER TWO LUBRICATION SYSTEM 2GM AND 2GM20 MODELS...

Page 46: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 55: ......

Page 57: ......

Page 58: ......

Page 64: ......

Page 66: ......

Page 70: ......

Page 71: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 112: ...106 CHAPTER SIX...

Page 114: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 145: ...FUEL INJECTION AND GOVERNOR SYSTEMS 139 FUEL INJECTION SYSTEM Fuel tank hose fuel pipe...

Page 148: ......

Page 149: ......

Page 150: ......

Page 151: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 165: ......

Page 170: ...164 CHAPTER EIGHT CLOSED COOLING SYSTEM TYPICAL rnlxlng elbow Joint...

Page 172: ......

Page 174: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 184: ......

Page 190: ......

Page 196: ......

Page 197: ......

Page 201: ......

Page 202: ......

Page 204: ......

Page 205: ......

Page 208: ......

Page 209: ......

Page 219: ......

Page 224: ...218 CHAPTER ELEVEN...

Page 231: ......

Page 235: ......