OPERATION, LUBRICATION, MAINTENANCE AND TUNE-UP

45

criteria that engine oils must meet to attain a diesel engine

oil classification of CA, CB, CC or CD. The classification

system ranges from CA for light diesel engine service to

CD for severe diesel engine service. Yanmar specifies en-

gine oils with classification CB or CC for use in the

Yanmar diesel engines covered in this manual.

Do not mix oil brands. For instance, do not add a differ-

ent oil brand than what is in the crankcase when topping

off the oil level, except if necessary. Use only a

high-quality oil. Yanmar recommends Shell

Caltex RPM Delo, Mobil Delvac, Esso Standard and BP

Energol.

Refer to Table

2 for the recommended oil viscosity.

Engine Oil Level Check

All engines will consume a certain amount of oil as a lu-

bricating and cooling agent. The amount depends on en-

gine use and engine condition. During the engine break-in

period, the engine consumes more oil while the piston

rings seat in the cylinder bore. Engines with high hours of

use may bum more oil due to

engine components.

Engines generally consume more oil at higher engine

speeds.

When to check engine oil is generally determined by

the engine's oil consumption rate. If the engine has a high

oil consumption rate, then check the oil level before each

use or daily. If engine oil consumption is low, check the oil

level weekly. The best procedure is to check the oil level

before operating the engine.

I

To

engine

Whenever checking the oil level, always allow approxi-

mately five minutes for the oil in the upper end to drain

back into the crankcase oil pan.

1. With the boat at rest in the water and the engine off,

pull out the dipstick. See Figure 1 for the typical location.

Wipe it with a clean rag or paper towel, reinsert it and pull

it out again. Note the oil level on the dipstick.

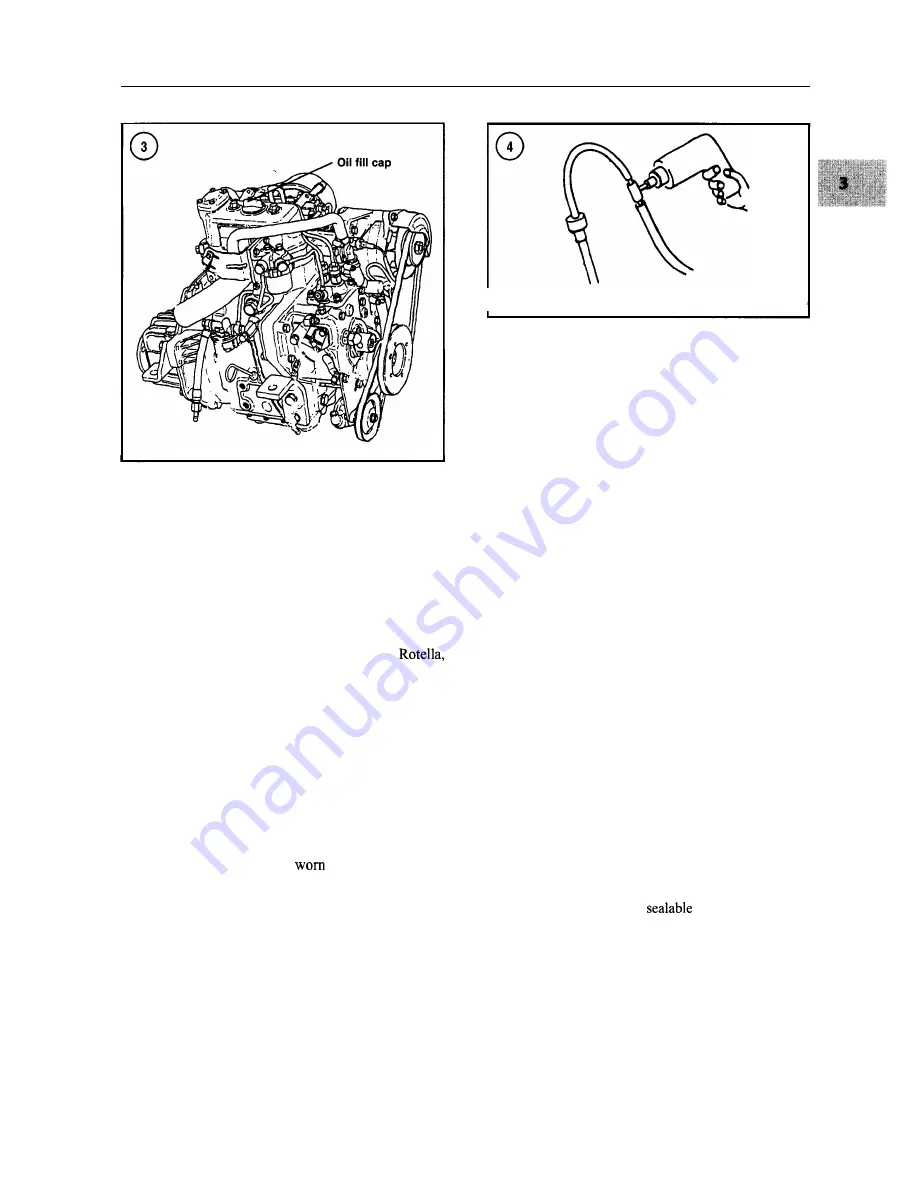

2. Add oil, if necessary, so the oil level reaches the full

mark on the dipstick. Remove the oil fill plug (Figure

2)

or oil filler cap (Figure

3) and add oil through the hole in

the rocker arm cover.

Engine Oil and Filter Change

During normal engine operation, change the engine oil

after every 100 hours of operation. Replace the engine oil

filter after every 300 hours of operation. During break-in

of a new or overhauled engine, change the engine oil after

the first 20 hours of use, then after the next 30 hours of

use. Change the engine oil at normal intervals thereafter.

Refer to the Engine Oil section in this chapter for the

recommended oil type. Refer to Table

2 for viscosity and

Table

3 for crankcase oil capacity.

Most installations do not leave enough space to permit

the use of the oil pan drain plug. For this reason, an oil

drain suction pump is the most common device used to

drain the crankcase oil. The pump has a long, flexible

hose, which is inserted into the oil dipstick tube and fed

into the crankcase. Several makes of pumps are available

from marine supply dealers. Some are hand-operated,

some are motorized and others are designed to be operated

with an electric drill (Figure 4).

Direct the used oil into a

container and prop-

erly dispose of it.

NOTE

Never dispose of motor oil in the trash, on

the ground, down a storm drain or over-

board. Many service stations accept used

Summary of Contents for 1GM10

Page 1: ...YANMAR DIESEL INBOARD SHOP MANUAL ONE TWO 8 THREE CYLINDER ENGINES...

Page 6: ......

Page 7: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ...GENERAL INFORMATION 21 Bearing Blocks Press Shaft arm Bearing Spacer Press k 4 bed...

Page 36: ...30 CHAPTER TWO CHARGING SYSTEM TYPICAL Battery switch...

Page 39: ......

Page 44: ...38 CHAPTER TWO LUBRICATION SYSTEM 2GM AND 2GM20 MODELS...

Page 46: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 55: ......

Page 57: ......

Page 58: ......

Page 64: ......

Page 66: ......

Page 70: ......

Page 71: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 112: ...106 CHAPTER SIX...

Page 114: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 133: ......

Page 134: ......

Page 135: ......

Page 136: ......

Page 145: ...FUEL INJECTION AND GOVERNOR SYSTEMS 139 FUEL INJECTION SYSTEM Fuel tank hose fuel pipe...

Page 148: ......

Page 149: ......

Page 150: ......

Page 151: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 165: ......

Page 170: ...164 CHAPTER EIGHT CLOSED COOLING SYSTEM TYPICAL rnlxlng elbow Joint...

Page 172: ......

Page 174: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 184: ......

Page 190: ......

Page 196: ......

Page 197: ......

Page 201: ......

Page 202: ......

Page 204: ......

Page 205: ......

Page 208: ......

Page 209: ......

Page 219: ......

Page 224: ...218 CHAPTER ELEVEN...

Page 231: ......

Page 235: ......