In order to keep the engine in top running condition, perform regular maintenance checks.

In this way small malfunctions can be detected and corrected before they lead to serious engine failure.

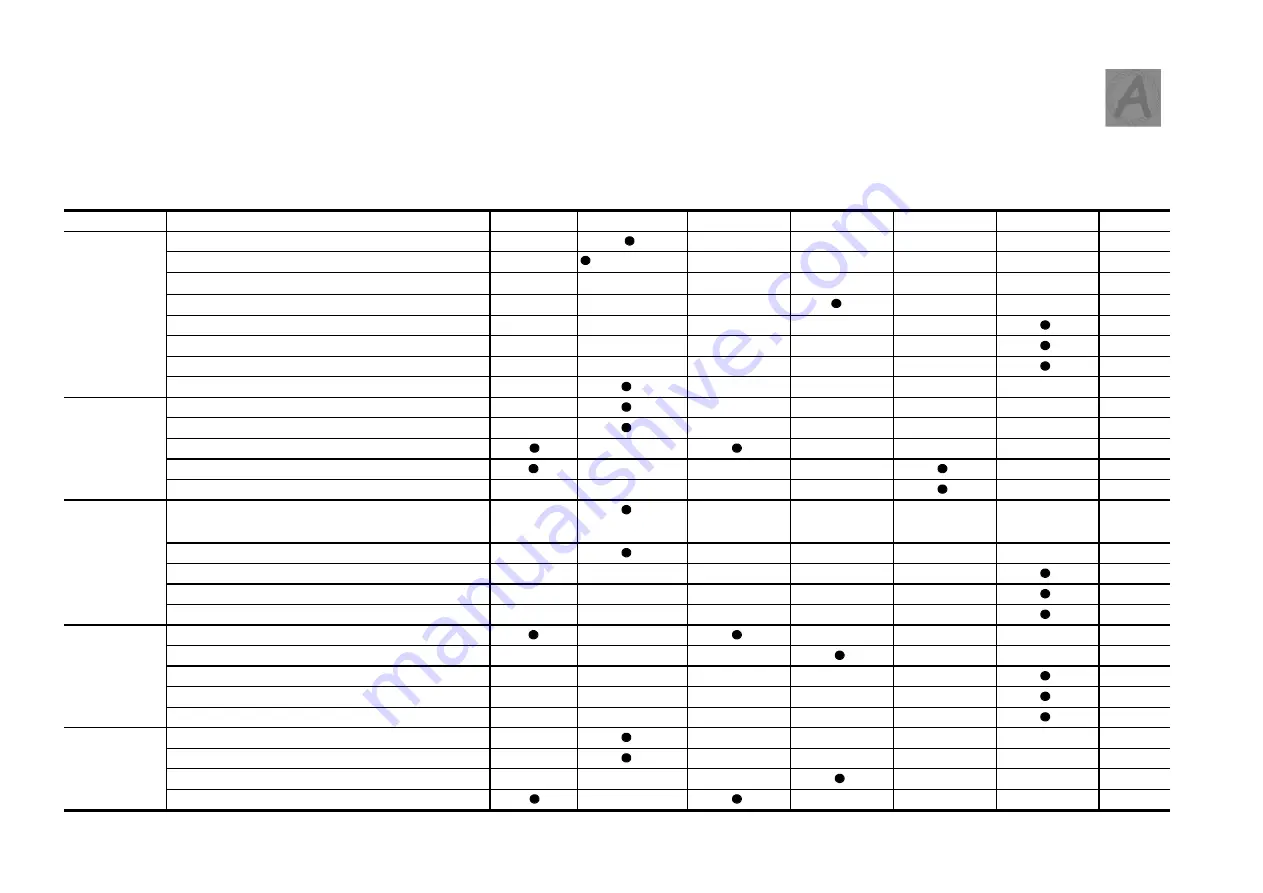

First 50 hrs.

Daily

Every 100 hrs. Every 250 hrs. Every 300 hrs. Every 500 hrs.

Note

Check and refil

Drain any deposit or dirt

Before refiling

Air venting from F.O. return pipe

Every 50 hrs.

Clean fuel filter element

Replace fuel filter element

fig. 1

Check fuel injection timing

Check fuel injection valve

Check fuel injection sound

Check oil level in crankcase and clutch case

Lubrication (starter chain etc.)

Change lub. oil in crankcase

fig. 2

Replace lub. oil strainer

fig. 3,4

Change lub. oil in clutch case

After operation

in cold water

Check cooling water circulation

Check water pump impeller

fig. 5

Clean thermostat

fig. 6

Check anticorrosive zinc

fig. 7,8

Retighten bolt

Adjust intake & exhaust valves clearance

Clean pre-combustion chamber

Lap intake & exhaust valves

Check valve stems & valve guides

Check battery electrolyte level

Check lamps (charging Lub. oil warning & C.W. warning)

Check belt tension

Retighten major bolts and nuts

Cooling water

Drain water

Cylinder head

Others

PERIODICAL CHECK

VIII

Item

Description

Fuel oil

Lub. oil