PERIODIC MAINTENANCE

TNV Operation Manual

93

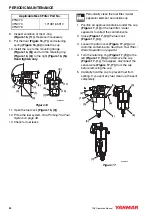

6. Remove the float ring

(Figure 17, (8))

from

the cup. Pour the contaminants into the

container and dispose of it properly.

7. Clean the element

(Figure 17, (9))

and inside

cup. Replace the element if it is damaged.

8. Install the element and O-ring in the bracket.

9. Position the float ring in the cup.

10. Check the O-ring. Replace if necessary.

11. Install the cup to the bracket by tightening the

retaining ring to the right

(Figure 17, (6))

.

Hand tighten only

.

12. Close the drain cock. Reconnect the sensor

wire if equipped.

13. Open the fuel cock.

14. Prime the fuel system.

See Priming The Fuel

15. Check for fuel leaks.

Perform the following maintenance every 1000

hours of operation.

• Drain, Flush and Refill Cooling System With

New Coolant

• Adjust Intake / Exhaust Valve Clearance

Drain, Flush and Refill Cooling

System With New Coolant

Applicable Element Part No.

3TNV82A, 3TNV84,

3TNV84T, 3TNV88,

4TNV84, 4TNV84T,

4TNV88, 4TNV94L,

4TNV98, 4TNV98T,

4TNV106,

4TNV106T

119802-55710

Every 1000 Hours of Operation

A

DANGER

0000002en

SCALD HAZARD!

• NEVER remove the radiator cap if the

engine is hot. Steam and hot engine

coolant will spurt out and seriously

burn you. Allow the engine to cool

down before you attempt to remove

the radiator cap.

• Securely tighten the radiator cap after

you check the radiator. Steam can

spurt out during engine operation if

the cap is loose.

• ALWAYS check the level of engine

coolant by observing the reserve tank.

• Failure to comply will result in death or

serious injury.

Summary of Contents for 2TNV70

Page 1: ......

Page 2: ......

Page 32: ...SAFETY 14 TNV Operation Manual ...

Page 116: ...PERIODIC MAINTENANCE 98 TNV Operation Manual ...

Page 140: ...SPECIFICATIONS 122 TNV Operation Manual ...

Page 141: ......

Page 142: ......