PERIODIC MAINTENANCE

TNV Operation Manual

79

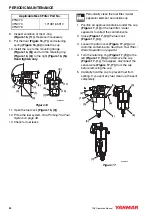

Figure 4

2. If necessary, adjust the V-belt tension. Loosen

the set bolt

(Figure 5, 1))

and move the

alternator

(Figure 5, 2))

with a pry bar

(Figure 5, 3))

to tighten the V-belt.

Figure 5

3. Check the V-belt for cracks, oil or wear. If any

of these conditions exists, replace the V-belt.

4. When installing a new V-belt, refer to the

New

V-belt Tension

table. After making the initial

belt tension adjustment, run the engine for at

least 5 minutes. Then recheck the v-belt

tension using the measurements in the

Used

V-belt Tension

table. Readjust as necessary.

Note: A “New V-belt” refers to a V-belt which

has been used less than 5 minutes on

a running engine.

0000652A

(A)

(B)

(C)

(A)

0000063A

(B)

(C)

New V-belt Tension

A

B

C

5/16 ~7/16 in

(8~12 mm)

3/16 ~5/16 in

(5~8 mm)

1/4 ~7/16 in

(7~11 mm)

(3)

(1)

(2)

0000653A

0000064A

(2)

(1)

(3)

Summary of Contents for 2TNV70

Page 1: ......

Page 2: ......

Page 32: ...SAFETY 14 TNV Operation Manual ...

Page 116: ...PERIODIC MAINTENANCE 98 TNV Operation Manual ...

Page 140: ...SPECIFICATIONS 122 TNV Operation Manual ...

Page 141: ......

Page 142: ......