5. Inspection and Servicing of Basic Engine Parts

93

5. Inspection and Servicing of Basic Engine Parts

5.1 Cylinder Block

The cylinder block is a thin-skinned, (low-weight), short

skirt type with rationally placed ribs. The side walls are

save shaped to maximize rigidity for strength and low

noise.

5.1.1 Inspection of parts

Make a visual inspection to check for cracks on engines that have frozen up, overturned or otherwise

been subjected to undue stress. Perform a color check on any portions that appear to be cracked, and

replace the cylinder block if the crack is not repairable.

5.1.2 Cleaning of oil holes

Clean all oil holes, making sure that none are clogged

up and the blind plugs do not come off.

5.1.3 Color check procedure

(1) Clean the area to be inspected.

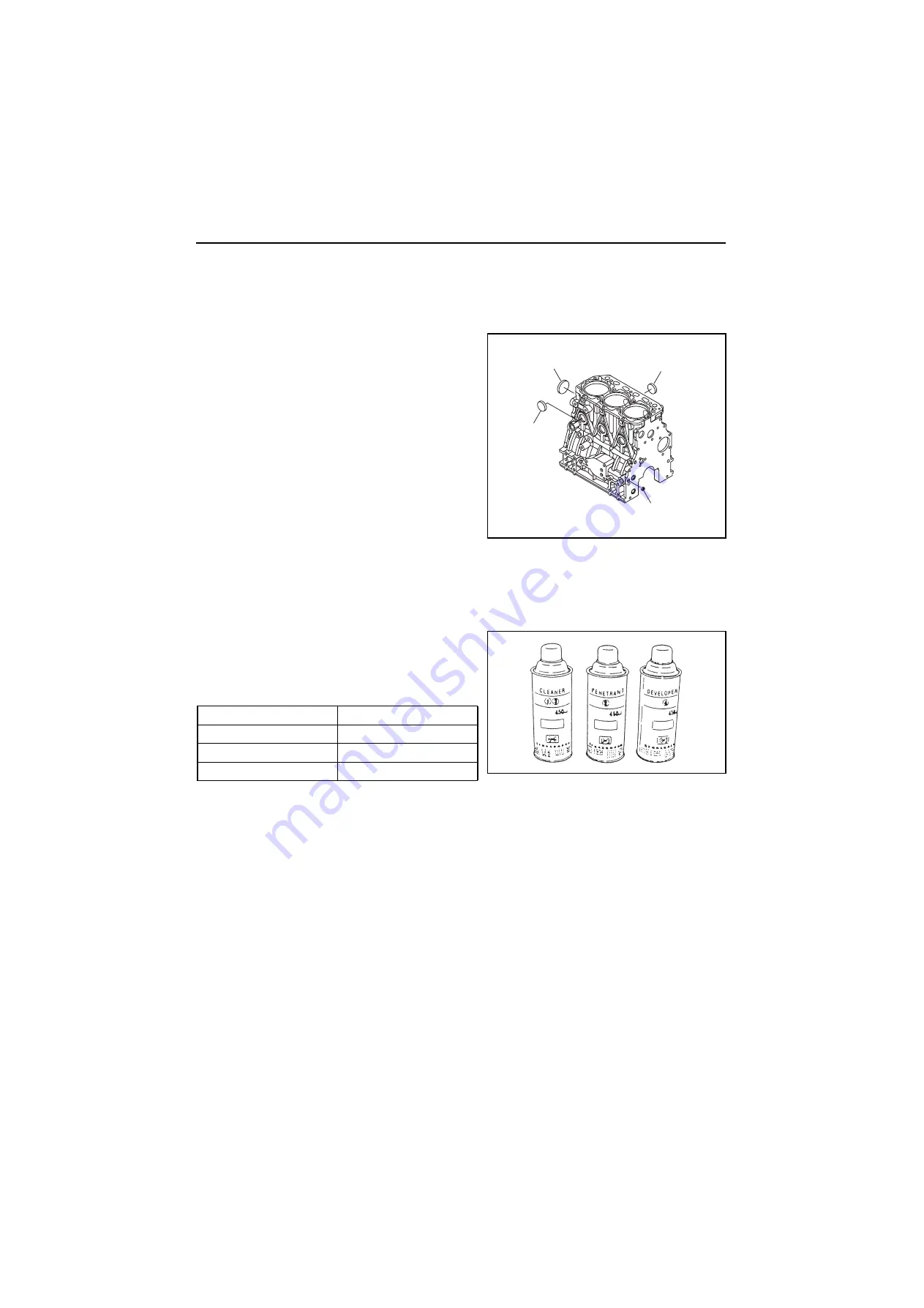

(2) Color check kit

The color check test kit consists of an aerosol cleaner, penetrant and developer.

(3) Clean the area to be inspected with the cleaner.

Either spray the cleaner on directly and wipe, or wipe the area with a cloth moistened with cleaner.

(4) Spray on red penetrant

After cleaning, spray on the red penetrant and allow 5-10 minutes for penetration. Spray on more red

penetrant if it dries before it has been able to penetrate.

(5) Spray on developer

Remove any residual penetrant on the surface after the penetrant has penetrated, and spray on the

surface after the penetrant has penetrated, and spray on the developer. If there are any cracks in the

surface, red dots or a red line will appear several minutes after the developer dries.

Hold the developer 300-400mm away from the area the surface uniformly.

Color check kit

Quantity

Penetrant

1

Developer

2

Cleaner

3

Cap plug 50 mm

(Camshaft hole)

Cap plug 30 mm

Cap plug 30 mm

Cap plug 12 mm

(main gallery)