5. Inspection and servicing of basic engine parts

127

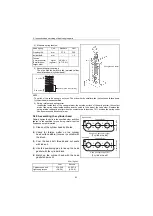

(4) Checking the side gap of a crankshaft

After assembling the crankshaft, tighten the main

bearing cap to the specified toque, and move the

crankshaft to one side, placing a dial gauge on one end

of the shaft to measure thrust clearance.

Replace the thrust bearing if it is worn beyond the limit.

Other measurement method can also be effective.

Insert the thickness gauge directly into the clearance

between the thrust metal and crankshaft thrust face.

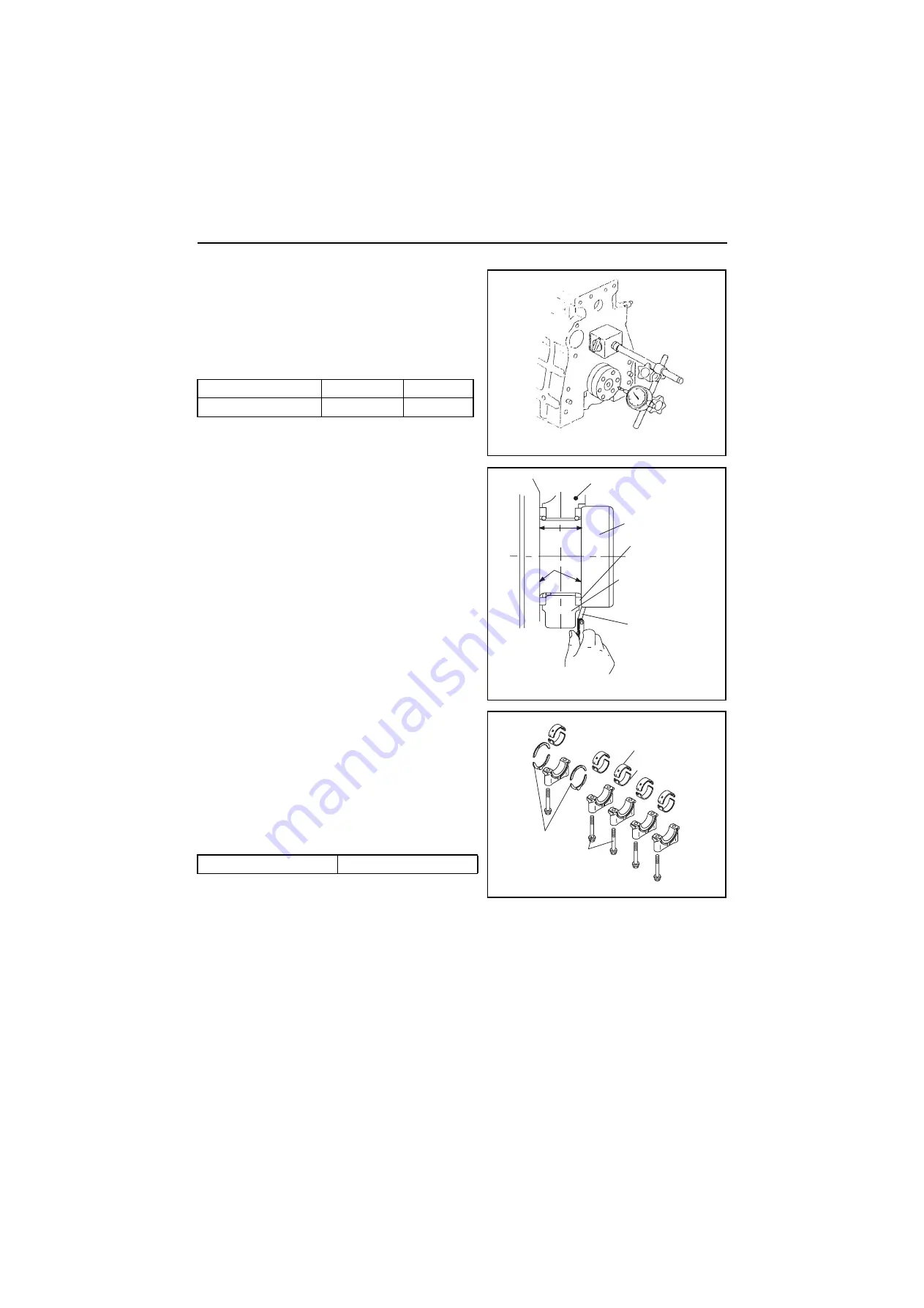

5.5.2 Main bearing

(1) Inspecting the main bearing

Check for flaking, seizure or burning of the contact

surface and replace if necessary.

(2) Measuring the inner diameter of metal

Tighten the cap to the specified torque and measure the

inner diameter of the metal.

NOTE:

When assembling the bearing cap, keep the following

in mind.

1) The lower metal (cap side) has no oil groove.

2) The upper metal (block side) has an oil groove.

3) Check the cylinder block alignment number.

4) The “FW” on the cap lies on the flywheel side.

mm

Standard

Limit

Crankshaft side gap

0.111-0.250

0.30

N•m (kgf•m)

Tightening torque

75.5-81.5 (7.7-8.3)

(Side gap measurement 1)

(Side gap measurement 2)

Cylinder block

Crankshaft

Thrust metal

Bearing cap

Standard

width

face

Thrust

Thickness gauge

Thrust metals

Block side main

bearing metals

Cap side main

bearing metals

(Main bearing)

Wheel side

Gear side

Main bearing bolt

Summary of Contents for 3YM20

Page 1: ...M9961 03E100 ...