2. Inspection and adjustment

25

(7) Adjust the propeller shaft alignment

The flexible engine mounts is compressed a little in the initial engine operation and it may cause the

centering misalignment between the engine & the propeller shaft.

1) Check unusual noise and vibration of the engine / boat hull, while increasing the engine speed

gradually and lowering it.

2) If there is unusual noise and/or vibration, adjust the propeller shaft alignment. (Refer to 6.4.5

"Centering the Engine" in the installation manual for pleasure boat use.)

2.2.3 Inspection every 50 hours or monthly

Be sure to check the following points every 50 hours or monthly, whichever comes first.

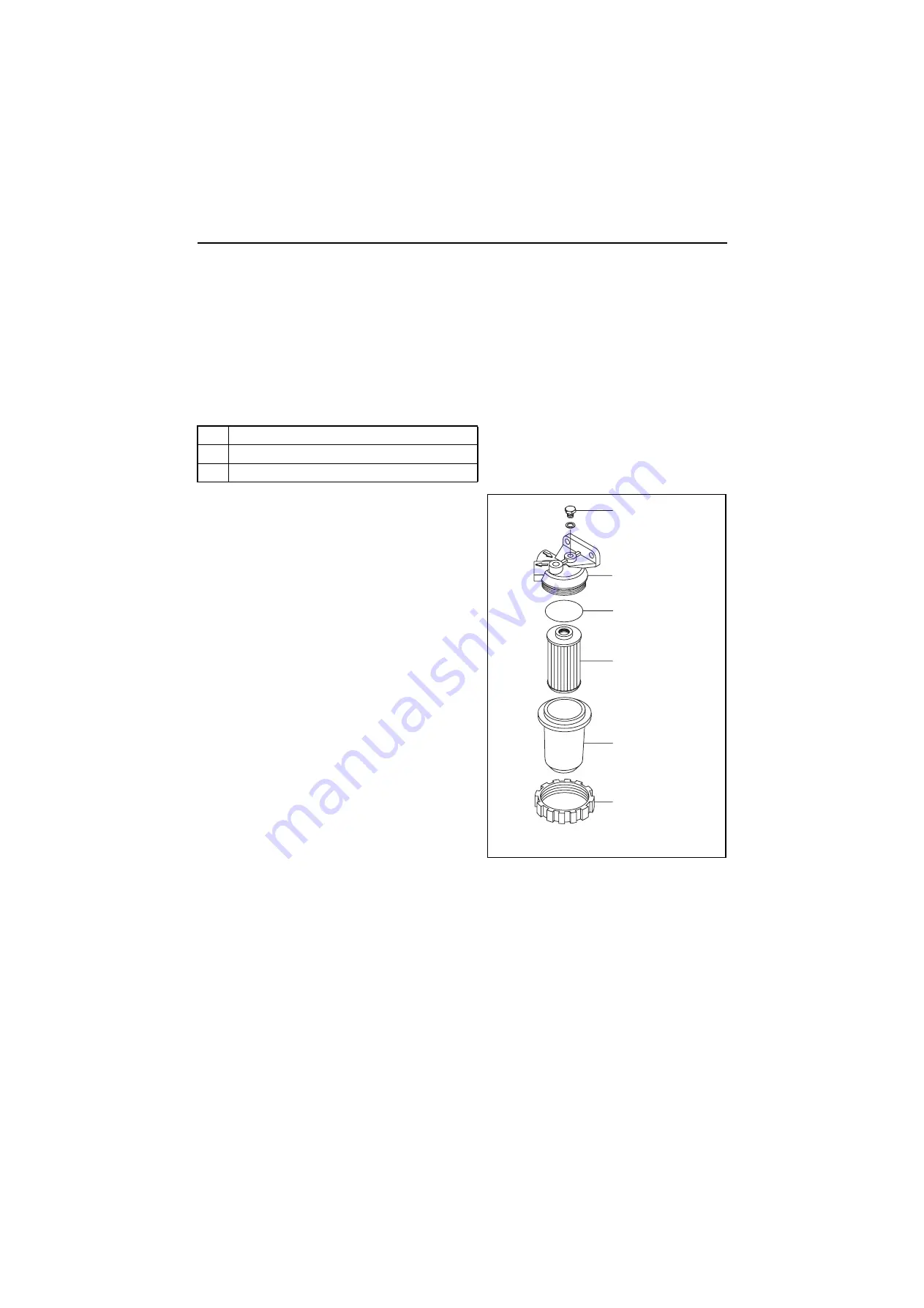

(1) Drain the fuel filter.

1) Close the fuel cock of a fuel tank.

2) Loosen the retaining ring and remove the filter cap.

Drain off any water and dirt collected inside.

3) After reassembly, be sure to vent air from the fuel

system.

If air is in the fuel system, fuel cannot reach the

fuel injection pump. Vent the air in the system

according to the following procedures.

Fuel system air bleeding procedures

1) Check the fuel level in the fuel tank. Replenish if

Insufficient

2) Loosen the air bleeding bolt at the top of the fuel

filter by turning it 2 or 3 times.

3) Feed fuel with the fuel feed pump by moving the

lever on the left side of the feed pump up and

down.

4) Allow the fuel containing air bubbles to flow out

from the air bleeding bolt hole. When the fuel no

longer contains bubbles, tighten the air bleeding

bolt. This completes the air bleeding of the fuel

system.

5) After the engine start-up, the automatic air-

bleeding device works to purge the air in the fuel

system. No manual air-venting is required for

normal engine operation.

No.

Inspection Item

(1)

Drain the fuel filter

(2)

Check the electrolyte level in the battery

(Fuel filter)

Air bleeding

Bracket

O-ring

Filter element

Filter cap

Retaining ring

Summary of Contents for 3YM20

Page 1: ...M9961 03E100 ...