8. Lubrication system

153

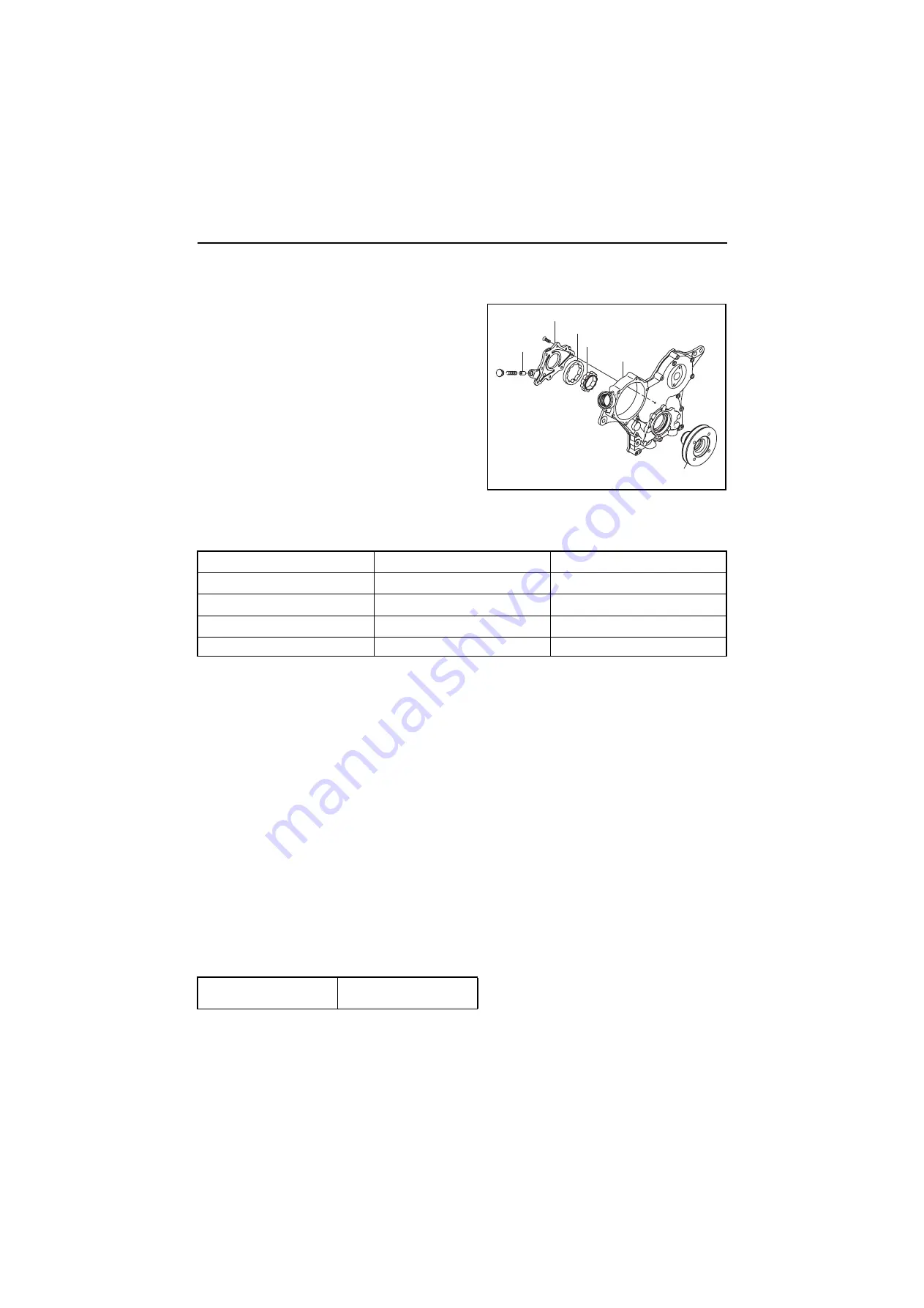

8.2 Lube oil pump

8.2.1 Lube oil pump construction

The trochoid type lube oil pump is mounted in the gear

case, and the inner rotor is driven by the crankshaft

pulley.

The lube oil flows from the intake filter mounted on the

bottom of the cylinder body through the holes in the

cylinder body and engine plate, and out from the holes

in the engine plate and cylinder body to the discharge

filter.

The lube oil pump is fitted with a control valve, which

controls the discharge oil pressure at the specified

pressure.

8.2.2 Specifications of lube oil pump

8.2.3 Lube oil pump disassembly and reassembly

Disassembly

(1) Remove the crankshaft pulley.

(2) Remove the gear case cover.

(3) Remove the lube oil pump cover from the gear case cover. Do not disassemble the

inner /outer rotors, and check that the pump rotates smoothly.

(4) Remove the pressure control valve from the lube oil pump cover.

Note :

Only wash the control valve. Disassembly is unnecessary unless any abnormality in operation is

detected.

Reassembly

[NOTICE]

Always check if the pump rotates smoothly after installation on the gear case.

Running the engine when the pump rotation is heavy may cause the pump to be burnt.

(1) Apply lube oil to rotor (outer/inner) insertion part.

(2) Fasten the pump cover by the standard torque.

(3) When replacing the lube oil pump, replace the whole assy.

Lube oil pump specifications

Engine speed

3600 (min

-1

)

800 (min

-1

)

Pump speed

3477 (min

-1

)

772 (min

-1

)

Delivery quantity

º

19.0 (l/ min

-1

)

º

8.0 (l/ min

-1

)

Delivery pressure

0.43 MPa (4.4 kgf/cm

2

)

º

0.049 MPa (0.5 kgf/cm

2

)

Oil temp.

60±5 (°C)

I

Tightening torque

5.9-7.9 N•m

(0.6-0.8 kgf•m)

Cover

Control

valve

Outer rotor

Inner rotor

Gear case cover

Crankshaft pulley

Summary of Contents for 3YM20

Page 1: ...M9961 03E100 ...