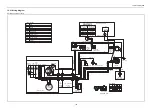

9. Cooling water system

171

9.7.2 Description

(1) Characteristics

1) Discharge at lift : 0 m discharge capacity : 20 liters/min. or greater.

2) Automatic feeding height : 1 m or greater

(Limit for automatic feeding height: new pump with inside parts wet, approx. 2 m)

3) Automatic feeding time : 2

-

5 seconds.

(Limit for automatic feeding time: new pump with inside parts wet, approx. 1 second.)

4) Automatic stopping : Air intake causes negative pressure triggering automatic stopping.

(2) Insulation

1) Insulation resistance : 500V with a megatester when the difference between the continuity point

and the body is 1M

Ω

or greater.

2) Insulation proof stress : AC50 between the continuity point and the body, or 60hz 500V for 1 minute

when impressed current leakage is 10 mA or lower.

(3) Durability

Rated voltage when there is 3% salt water 60L + engine oil 3%, and operation is at 1800 cycles and

there are no difficulties.

(4) Vibration proof

Amplitude 0.51 mm (one side of the amplitude)

Vibration frequency 10-55 Hz

Sweep time 90 seconds.

Direction of vibration each direction 4 hours

No difficulties after test period

9.7.3 Cautions

(1) Attach at a position higher than the bilge water away from rain or other water, and 50-

70 cm above the bottom of the boat.

(2) Never run the pump dry. Be sure that the strainer is inserted in the drain water before

pushing the switch. If no water is being drawn up after a period of 10 seconds or more,

prime the pump. (Do not run the pump for longer than 10 seconds when no water is

being drawn up.)

(3) When the pump has not been used for a long period of time, the inside of the pump will

be dry and drawing ability will be lowered. Before reusing, clean the inside of the pump

or prime it to insure that it is wet, and check to be sure that the pump is then operating

correctly.

(4) When charging the diesel engine oil, wait a period of 30 minutes or longer from the

time of stopping (oil temperature 20-70°C). Refrain from operation when the oil

temperature is below 15°C, or above 50°C.

(5) When the bilge inside the pump or hose freezes, completely melt the water with a

steaming towel before beginning operation. When the temperature inside the pump is

low, it will take a longer amount of time for the pump to drain off the bilge.

(6) The impeller replacement kit includes one impeller and 3 washers for adjusting the

side gap. If after replacing the impeller the pump does not drain, place side gap

adjustment washers underneath the bottom plate to adjust. Select the number of

washers used in accordance with the following. (When the pump is draining, the

electric current load is about 5A. When there are too many washers, the electric

current value will be too great and will blow a fuse.)

Summary of Contents for 3YM20

Page 1: ...M9961 03E100 ...