FUEL SYSTEM

Repair

12/05

BY Service Manual

6-13

© 2009 Yanmar Marine International

10. Use compressed air to blow debris out of cavity

while covering cavity with cloth to catch debris.

WARNING! Flying Object Hazard. ALWAYS

wear eye protection when servicing the

engine and when using compressed air or

high-pressure water. Dust, flying debris,

compressed air, pressurized water or steam

may injure your eyes.

11. Inspect to ensure sealing surface is clean.

Repeat cleaning if necessary.

12. Use special tool OEM No. 13 5 214 to remove

tip (special tool OEM No. 13 5 215) from bottom

of injector cavity. See Install Fuel Injector on

page 6-13.

13. Install fuel injector and high-pressure line. See

Install Fuel Injector on page 6-13.

14. Run engine and check for fuel leaks.

Install Fuel Injector

1. Make sure that the old gasket is not at the

bottom of the injector seat. Clean the sealing

surfaces of the injector seat. See Clean Fuel

Injector Cavities on page 6-12.

2. Inspect the O-ring and replace as necessary.

Lubricate the O-ring with petroleum jelly.

NOTICE: ALWAYS install new copper gasket

when installing an injector. Make sure all

sealing surfaces are clean.

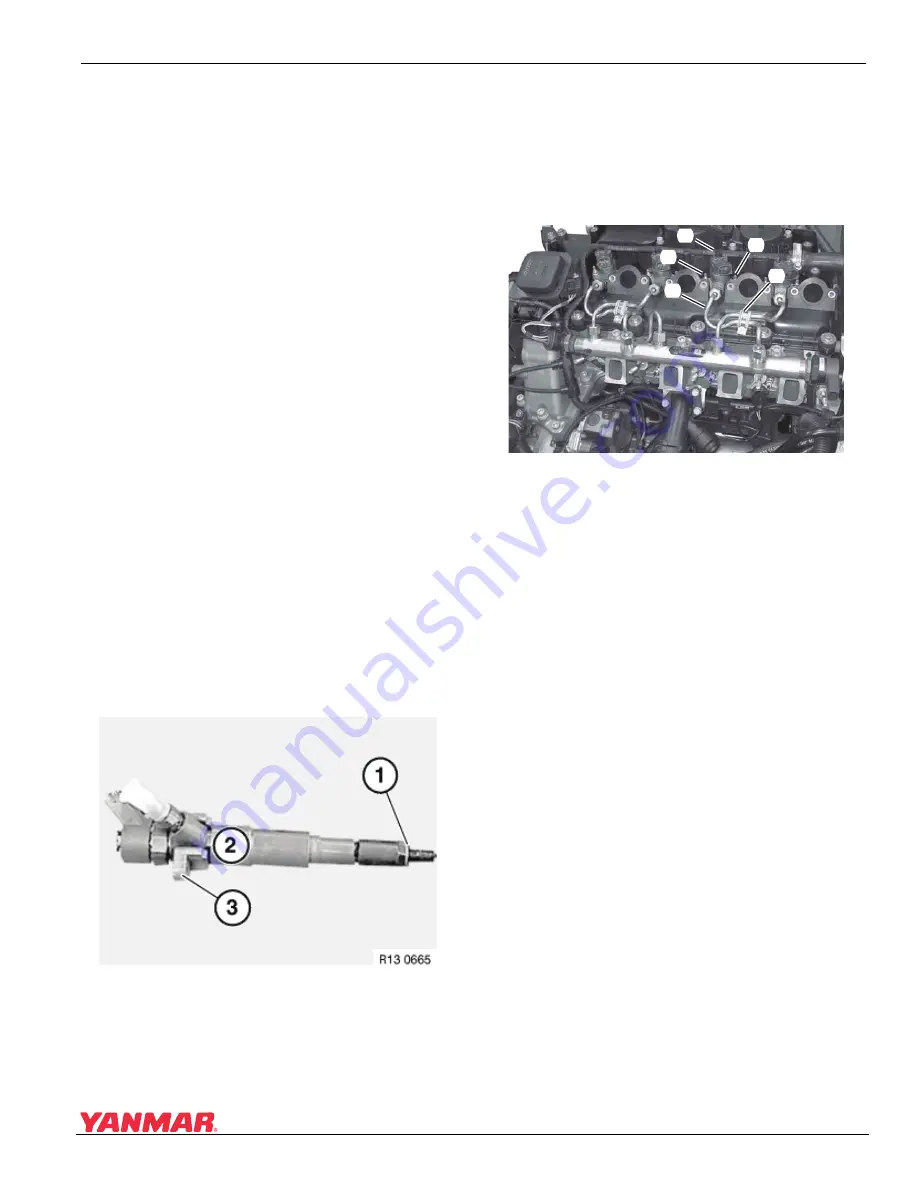

3. Install new gasket (Figure 6-17, (1)) on tip of

injector (Figure 6-17, (2)).

Figure 6-17

Figure 6-17

4. Place the retainer (Figure 6-17, (3)) on the

injector as shown.

Note: If installing used fuel injectors, clean the

stem and nozzle prior to installation.

5. Install the injector and retainer as an assembly.

6. Install the two nuts (Figure 6-18, (1)) and

tighten in steps, first to 3.5 N·m (31 in.-lb) then

to 8 N·m (71 in.-lb).

Figure 6-18

Figure 6-18

7. Install the high-pressure fuel line

(Figure 6-18, (2)). See Remove and Install

High-Pressure Fuel Lines on page 6-14.

8. If removed, install clamp (Figure 6-18, (3)).

9. Install injector return fuel lines

(Figure 6-18, (4)). See Replace Injector Return

Fuel Line on page 6-21.

10. Install intake manifold. See Intake Manifold on

11. Open all fuel supply valves.

12. Connect the battery negative (-) cable.

13. Fill and bleed fuel system. See Bleed the Fuel

14. Start the engine and check for fuel leaks. Allow

the engine to run until it is running smoothly.

WARNING! Piercing Hazard. NEVER check

for a fuel leak with your hands. ALWAYS use

a piece of wood or cardboard.

15. Check and delete any trouble codes that are

registered in the ECU after the work has been

completed.

000

3

677A

(

3

)

(2)

(1)

(4)

(1)