SERVICE MANUAL

REVISED: FEBRUARY 2009

Read and observe all warnings on this unit

before operating it.

DO NOT

operate this equipment unless all

factory installed guards and shields are

properly secured in place.

WARNING

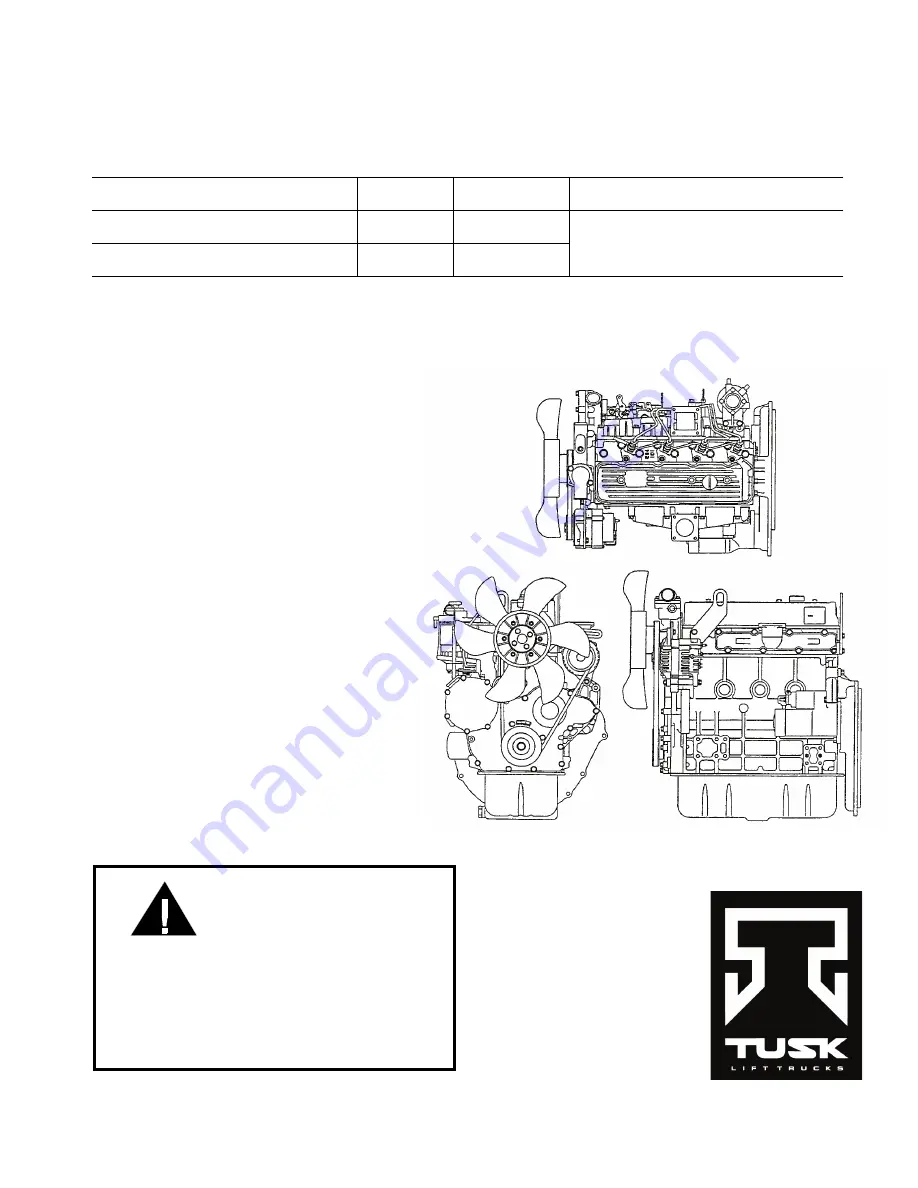

4D94(L)E / 4D98E DIESEL ENGINES

Federal Environmental Protection Agency (EPA) Emission Control Compliant

BX20 S/N 580001A~

4D94(L)E EPA TIER 2 400/500/600PD-14

BX50 S/N 200001A - 215882A 4D94(L)E EPA TIER 2

400/500/550/600/650/700PD-16

BX50 S/N 215883A~

4D98E

EPA TIER 3

SM197T

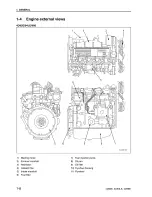

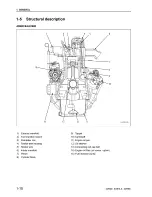

4D94E-BE4

4D94(L)E

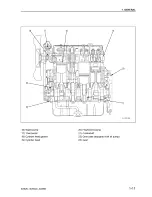

4D98E