2

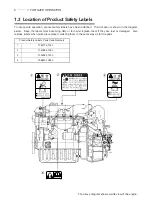

1. FOR SAFE OPERATION

1.2 Safety Precautions

(Observe these instructions for your own safety.)

Precautions for Operation

Burns from Scalding

• Never remove the filler cap of the fresh water cooler while the engine is still

hot. Steam and hot water will spurt out and seriously burn you. Wait until

the water temperature has dropped, then wrap a cloth around the cap and

loosen it slowly.

• After inspection, refasten the filler cap firmly. If the cap is not secure, steam

or scalding water may be emitted during operation causing burns.

Proper Ventilation of the Battery Area

• Be sure the area around the battery is well-ventilated and there is nothing

which could start a fire. During operation and charging, hydrogen gas is

emitted from the battery and can be easily ignited.

Fires from Oil lgnition

• Be sure to use the correct type of fuel when refueling.

Mistakenly filling with gasoline or the like will result in ignition.

• Be sure to stop the engine before refueling.

If you spill fuel, wipe such spillage carefully.

• Never place oils or other flammable material close to the engine as this

could result in ignition.

Exhaust Gas Poisoning

• Be sure to establish good ventilation in the engine room with windows,

vents, or other ventilation equipment. Check again during operation to be

sure that ventilation is good. Exhaust gas contains poisonous carbon mon-

oxide and should not be inhaled.

Moving Parts

• Do not touch the moving parts of the engine (propeller shaft, V-belt, PTO-

pulley, etc.) during operation or let your clothing get caught in them as this

can result in injury.

• Never operate the engine without the covers on the moving parts.

• Check before starting the engine to see that any tools or cloths used in

maintenance have been removed from the area.

Burns from Contact with Hot Engine Parts

• The whole engine is hot during operation and immediately after stopping.

The turbocharger, exhaust manifold, exhaust pipe, and engine are very hot.

Never touch these parts with your body or clothing.

Summary of Contents for 4JH3-DTE

Page 30: ......

Page 39: ......

Page 40: ......

Page 51: ......

Page 55: ...MEMO ...

Page 64: ...4JH3 TE TCE HTE DTE 49961 202851 Operation Manual Models Marine Engine Code No ...

Page 65: ......