_

26

_

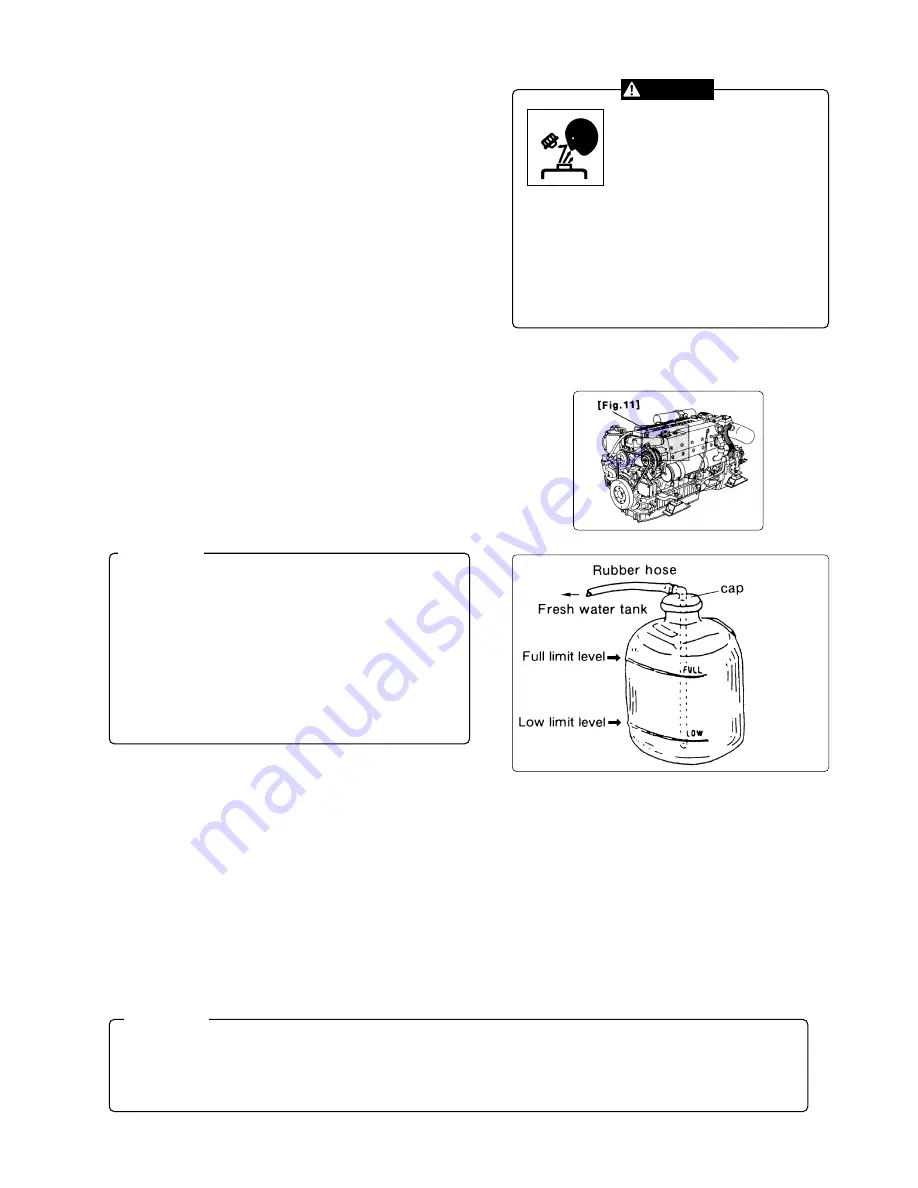

(5) Checking and Resupplying Cooling Fresh Water

Check the fresh water level before operation

while the engine is cold.

Checking the water level while the engine is hot

is dangerous, and the cooling water reading will

be misleading due to thermal expansion.

Only check and resupply fresh water routinely at

the subtank. Do not remove the filler cap of the

fresh water tank during operation.

1)

Check that cooling fresh water level is in

betweer Full and Low mark on the side of

the sub-tank.

2)

If the water level is below to the Low level

mark, open the sub-tank cap and supply

fresh water.

3)

When the water in the sub-tank runs out,

open the filler cap of the fresh water tank and

supply water until it overflows from the filler

port.

(See 3. 2. 4)

(Note)

The water level rises in the sub-tank during engine operation. This is not an abnormality.

After stopping the engine, the cooling water cools down and the extra water in the sub-tank

returns to the fresh water tank.

(6) Checking the Remote Control Handle

Be sure to check that the remote control handle lever moves smoothly before use it. If it is

hard to operate, Iubricate the joints of the remote control cable and also the lever bearings.

(See 4. 3. 4 (3),(4).)

If the cooling fresh water runs out too often,

or only the cooling fresh water in the fresh

water tank falls without any change in the

water level of the sub-tank, there may be

some leakage of water or air.

In such cases, consult your Yanmar dealer

or distributor without delay.

If the shift stroke of the remote control cable is inadequate at the marine gear end,

it may be impossible to shift into either ahead or astern or clutch (marine gear)

slippage may occur.

Do not open the filler cap

during operation or imme-

diately after stopping the

engine.

Hot steam and water will spout out. To

remove the cap, wait until the engine

has cooled down, wrap the cap with a

cloth and loosen the cap slowly. After

checking, fasten the filler cap firmly.

[NOTICE]

[NOTICE]

DANGER

Checking

cooling

fresh water

level