PERIODIC MAINTENANCE

8LV Series Operation Manual

37

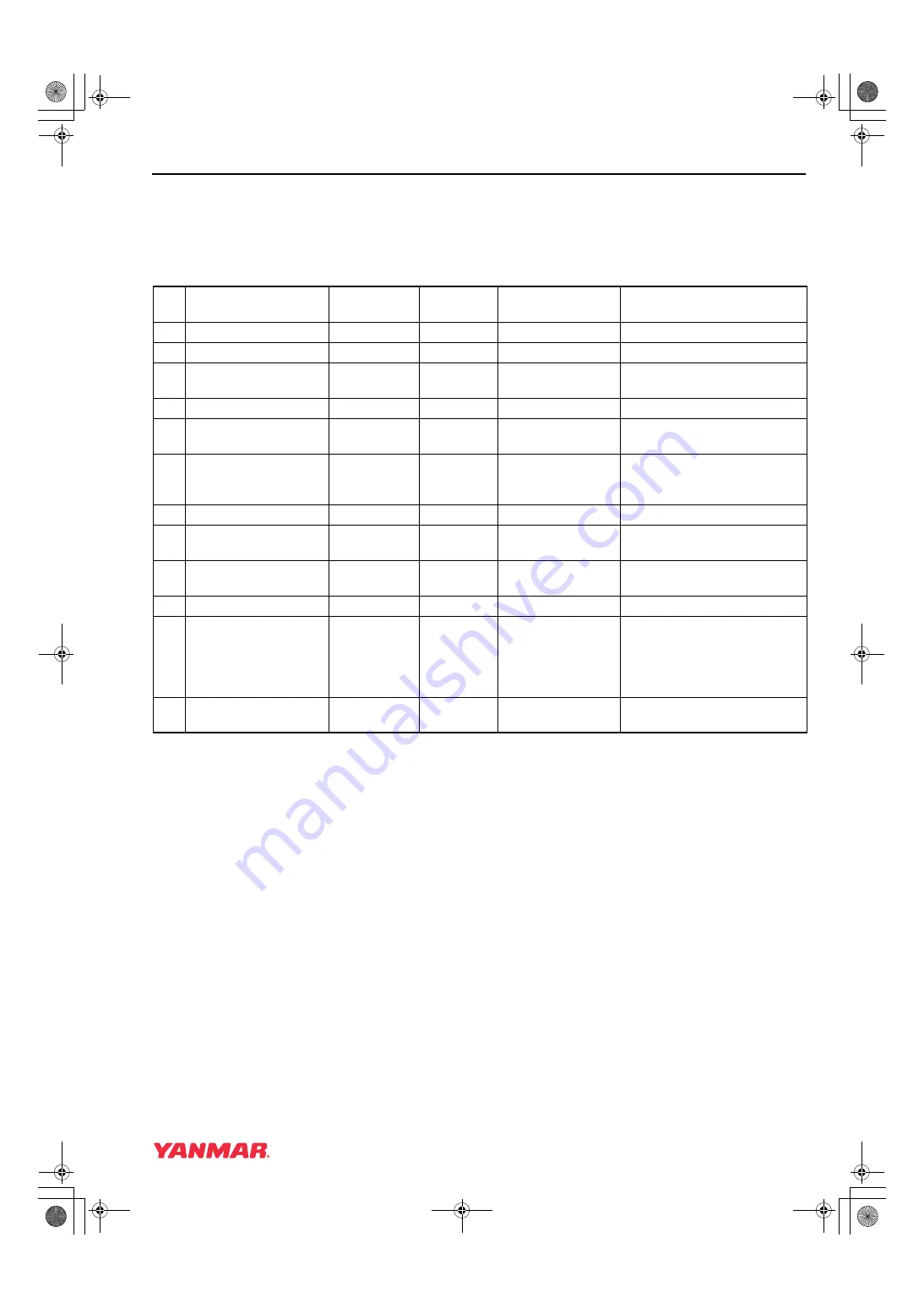

Tightening Fasteners

Use the correct amount of torque when you tighten fasteners on the machine. Applying excessive torque

may damage the fastener or component and not enough torque may cause a leak or component failure.

■

Main Bolt and Nut Tightening Torque

No.

Tightening Parts

Thread

Dia.

×

Pitch

Material

Lubricant

Tightening Torque

N·m (kgf-m)

1

Exhaust Manifold

M10

×

1.25

S45C

–

36 ± 4 (3.7 ± 0.4)

2

Mounting Foot

M12

×

1.25

SCM435

–

80 ± 10 (8.2 ± 1.0)

3

Union, Lubricating Oil

Filter

3/4 - 16 UNF

Apply lubricating oil

43.1 (4.4)

4

Lubricating Oil Filter

3/4 - 16 UNF

Apply lubricating oil

14.7 - 19.6 (1.5 - 2.0)

5

Bolts, Installation of

Seawater Pump

M8

×

1.25

S45C

–

20 ± 3 (2.0 ± 0.3)

6

Support, Lubricating

Pipe (Lubricating Oil

Filter in/out)

M8

×

1.25

S45C

–

5 ± 1 (0.5 ± 0.1)

7

Nut, Starter B Terminal

M8

×

1.25

S45C

–

21 ± 2 (2.1 ± 0.2)

8

Bracket, EDU (Head

Cover Insert of Resin)

M6

×

1

S45C

–

10 ± 1 (1.0 ± 0.1)

9

Battery Terminal (Head

Cover Insert of Resin)

M6

×

1

S45C

–

10 ± 1 (1.0 ± 0.1)

10

Nut, Battery Terminal

M8

×

1.25

–

10 ± 1 (1.0 ± 0.1)

11

V Band, Turbo-charger

and Mixing Elbow

Apply Molybdenum

Coat on the threads

After tightening at 6 ± 1 (0.6 ±

0.1), hit the outer circumference

with a plastic hammer (3 times

evenly at 3 places or more), and

retighten at 6 ± 1 (0.6 ± 0.1).

12

Bolts, Installation of

Vibration Isolator

M16

×

2

SMC435

–

196 ± 10 (20.0 ± 1.0)

8LV_OPM.book 37 ページ 2011年1月11日 火曜日 午後12時8分