ENGINE OPERATION

L-N Operation Manual

43

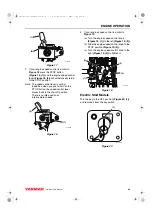

ADJUST ENGINE SPEED

Use the engine speed control to adjust the engine

speed for the task that will be performed.

Several types of engine speed controls are used

in L-N engine applications. The following

procedures are for three typical applications.

Refer to the operating instructions for the driven

machine.

1. If your engine speed control is similar to

Figure 14

slide the engine speed control

lever

(Figure 14, (1))

in the direction shown to

adjust the engine speed.

Note: This is a friction adjustment. If the

speed control will not maintain a given

speed, tightening the nut will increase

the friction on the speed control lever.

Figure 14

2. If your engine speed control is similar to

slide the engine speed control

lever

in the direction shown to

adjust the engine speed.

Note: This type of speed control, typically

used on a generator set, has only one

speed setting. When you move the

lever to the right, it clicks into the RUN

position. The speed control lever is

spring-loaded so when you push down

on the STOP button, the speed control

lever moves back to the shut-off

position. There is no idle position or

intermediate speeds.

Figure 15

CAUTION

New Engine Break In:

• On the initial engine start-up, allow the

engine to idle for approximately 15

minutes while you check for proper

engine oil pressure, diesel fuel leaks,

engine oil leaks, and for proper

operation of the indicators and / or

gauges.

• During the first hour of operation, vary

the engine speed and the load on the

engine. Short periods of maximum

engine speed and load are desirable.

Avoid prolonged operation at

minimum or maximum engine speeds

and loads for the next 100 hours.

• During the break-in period, carefully

observe the engine oil pressure and

engine temperature.

• During the break-in period, check the

engine oil levels frequently.

0000011en

S

TOP

S

LOW

RUN

0001

3

54B

(1)

RUN

S

TOP

(1)

0001

3

55B

LN Series OperationManual_A4.book 43 ページ 2006年5月12日 金曜日 午前10時18分