26 | RMB/ENERGIE GmbH

assembly

Operation manual CHP 5.0 - 30.0 | Status 01.2020

5.4 Test run

Once the installation process has been successfully

completed, it is necessary to perform a test run. The

system must run for a minimum of 15 minutes.

The factory setting of the system on delivery enables

the test run to run for maximum one hour. The system

will then automatically switch off.

Brief overview:

5.4.1 Opening the generation unit

5.4.2 Preparing the expansion tank connection block

5.4.3 Replenishing the cooling water

5.4.7 Closing the generation unit

5.4.1 Opening the generation unit

D

WARNING!

Risk of burns from hot components!

During operation, the components inside the generation

unit become very hot.

A

Use work gloves.

A

Only touch components if it is necessary to do so

for the work step.

A

Open the generation unit.

5.4.2 Preparing the expansion tank connection

block

D

ATTENTION!

Risk of material damage to the generation unit!

If the connection between the expansion tank

connection block and the generation unit is interrupted

during operation, the water supply to the generation

unit can burst.

A

Ensure that the expansion tank connection block is

correctly connected to the generation unit.

A

Open the valve for the expansion tank connection

block on the generation unit.

A

Remove the valve lever.

A

Store the valve lever in a safe place.

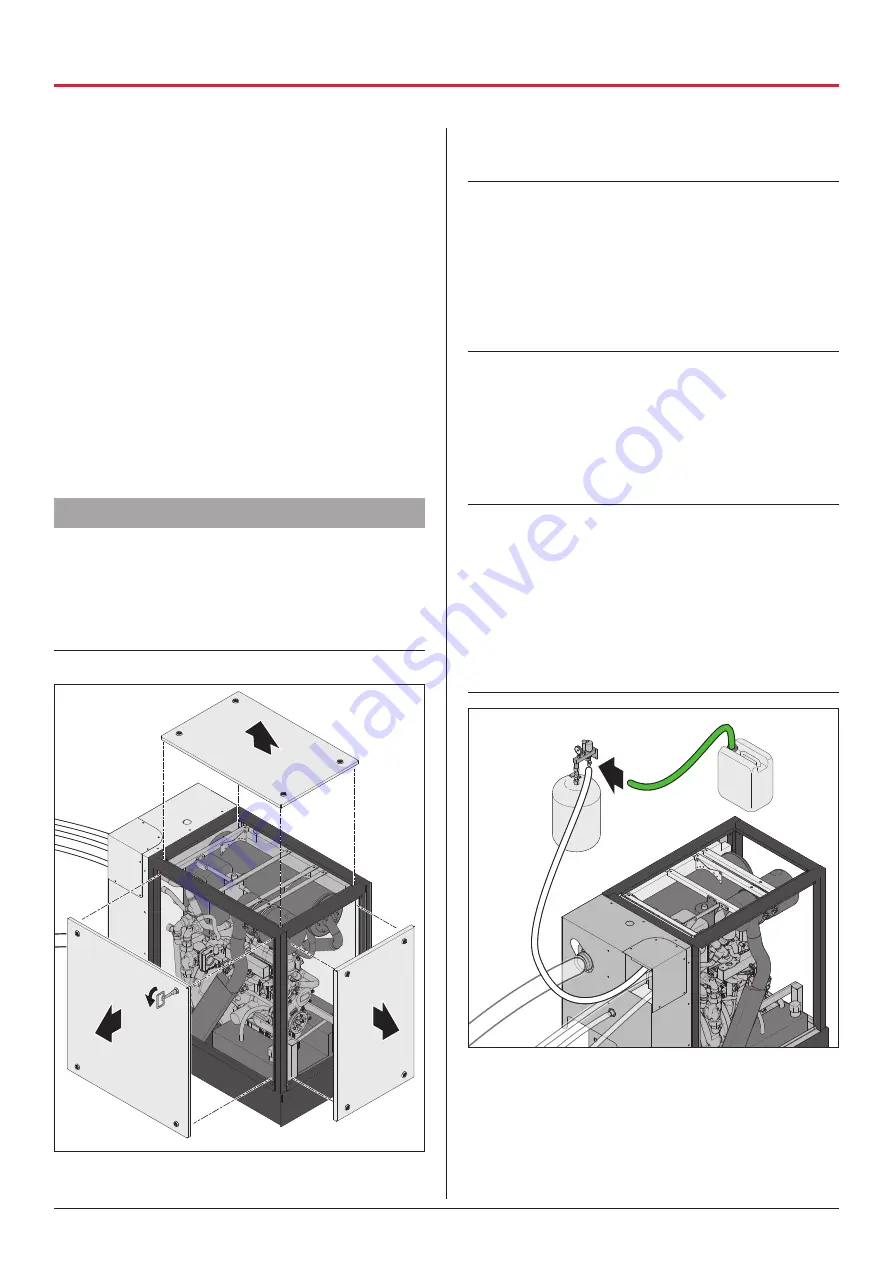

5.4.3 Replenishing the cooling water

D

ATTENTION!

Hazard caused by contamination of the cooling

system!

Contaminated or incorrect cooling medium will damage

the generation unit’s cooling system.

A

Only use original cooling medium (water-glycol

mixture 60:40) from the manufacturer.

A

Only use pumps for filling that have been cleaned

and are free from other substances.

A

Connect the pump for the cooling medium to the

fill-and-drain valve of the expansion tank connection

block.

A

Fill the system with cooling medium (water-glycol

mixture 60:40) until an operating pressure is

achieved of 2.0 bar in warm condition, 1.8 bar in

cold condition.