RT70 Operator’s Manual

Backhoe - 101

Finish Job

Finish Job

1. Raise stabilizers fully.

2. Move throttle to low.

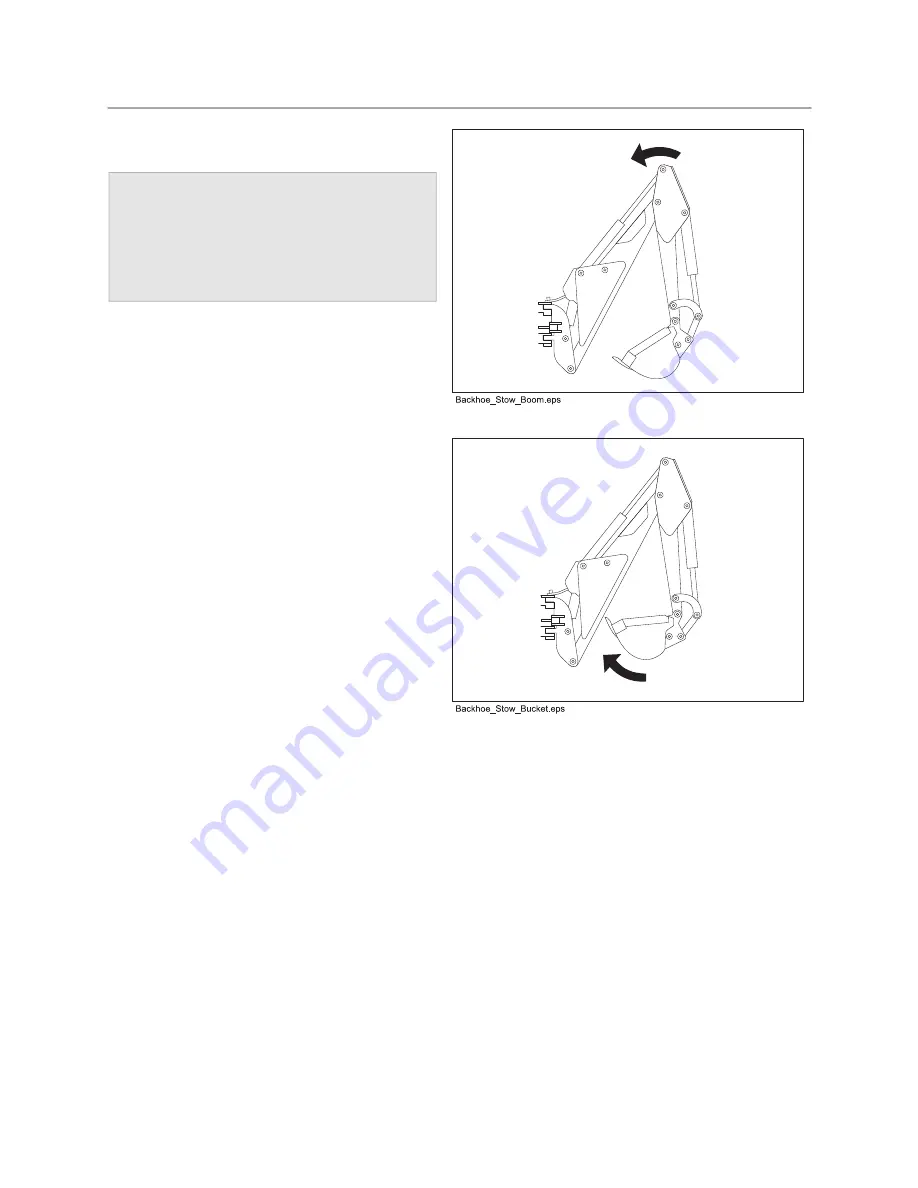

3. Lift boom while keeping dipper pointed at

ground (shown).

4. Curl bucket closed and move dipper fully

toward boom (shown).

5. Engage swing lock.

6. Rotate seat into stowed position.

7. Return to tractor seat and drive a short

distance away from work site.

8. Shut off machine.

IMPORTANT:

For tractor to function once

operator has returned to operator station,

stabilizers must be raised, remote throttle

must be disabled, remote stop must be

disengaged, and boom must be stowed and

locked.

Summary of Contents for RT70

Page 9: ...Overview 8 RT70 Operator s Manual About This Manual ...

Page 19: ...Safety 18 RT70 Operator s Manual Emergency Procedures ...

Page 31: ...Safety 30 RT70 Operator s Manual Attachment Safety Alerts ...

Page 83: ...Controls 82 RT70 Operator s Manual Seat ...

Page 89: ...Drive 88 RT70 Operator s Manual Shut Down ...

Page 97: ...Transport 96 RT70 Operator s Manual Haul ...

Page 103: ...Backhoe 102 RT70 Operator s Manual Finish Job ...

Page 123: ...Reel Carrier 122 RT70 Operator s Manual Finish Job ...

Page 129: ...Trench 128 RT70 Operator s Manual Finish Job ...

Page 141: ...Systems and Equipment 140 RT70 Operator s Manual Counterweights ...

Page 221: ...Specifications 220 RT70 Operator s Manual EU Declaration of Conformity ...