6

. HYDRAULIC SYSTEM

6-4-4

6

-4-4

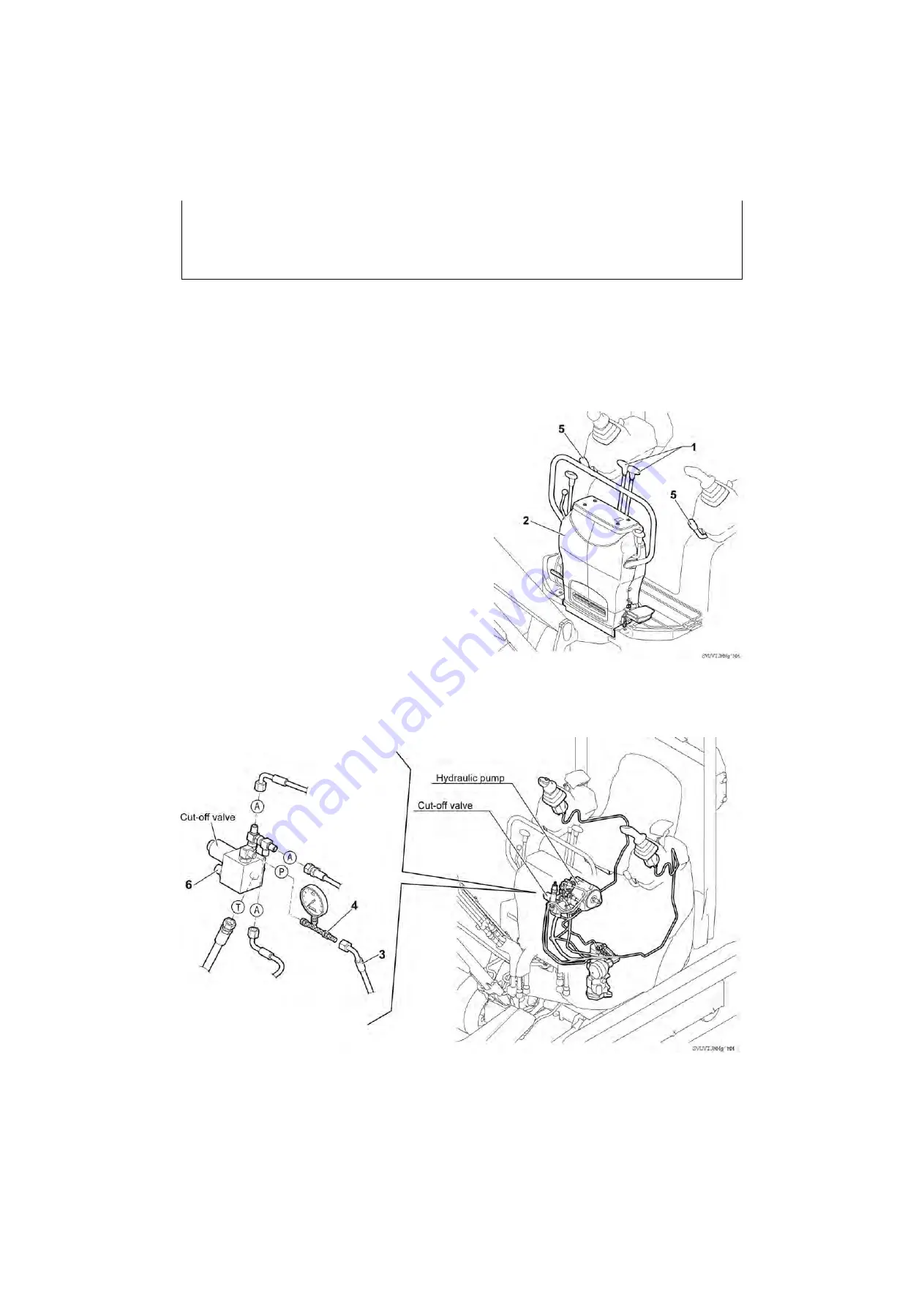

Cut-Off Valve

1) Conditions

(1)

Engine : rated speed

(2)

Hydraulic oil temperature : 150 to 60 °C

(3)

Pressure gauge capacity :

9.8 MPa

(4)

Set pressure : 2.5 to 2.7 MPa

2) Measurement Position

(1) Remove the grips

1

of the right and left travel levers,

remove the stand cover R

2

, and then disconnect

the connectors of the wiring.

(2) Install the pressure gauge

4

to the hydraulic hose

3

between the pilot pump and the cut-off valve.

3) Measurement Procedure

(1) Raise the hydraulic oil temperature to 50 to 60

degrees, run the engine at rated speed and place

the lock lever

5

in the lock position. Then, read the

pressure gauge

4

to check the pressure.

*The pressure is normal if it is

2.5 to 2.7 MPa.

4) Adjustment Procedure

Adjust the pressure of the relief valve

6

to a specified

value, which is between 2.5 to 2.7

MPa.

Summary of Contents for ViO12-2A

Page 1: ...SERVICE MANUAL EXCAVATOR ViO12 2A...

Page 2: ......

Page 3: ......

Page 9: ......

Page 21: ......

Page 23: ......

Page 37: ......

Page 55: ......

Page 57: ......

Page 99: ......

Page 109: ...5 3 1 5 ELECTRIC SYSTEM 5 3 Wiring Diagram...

Page 114: ......

Page 117: ...6 HYDRAULIC SYSTEM 6 1 3...

Page 118: ...6 HYDRAULIC SYSTEM 6 1 4...

Page 119: ...6 HYDRAULIC SYSTEM 6 1 5 This Page Intentionally Left Blank...

Page 121: ...6 HYDRAULIC SYSTEM 6 1 7...

Page 122: ...6 HYDRAULIC SYSTEM 6 1 8...

Page 123: ...6 HYDRAULIC SYSTEM 6 2 1 6 2 Hydraulic Circuit Schematic...

Page 125: ...6 HYDRAULIC SYSTEM 6 3 2...

Page 126: ...6 HYDRAULIC SYSTEM 6 3 3...

Page 127: ...6 HYDRAULIC SYSTEM 6 3 4 This Page Intentionally Left Blank...

Page 129: ...6 HYDRAULIC SYSTEM 6 3 6...

Page 130: ...6 HYDRAULIC SYSTEM 6 3 7...

Page 131: ...6 HYDRAULIC SYSTEM 6 3 8 This Page Intentionally Left Blank...

Page 133: ...6 HYDRAULIC SYSTEM 6 3 10...

Page 134: ...6 HYDRAULIC SYSTEM 6 3 11...

Page 135: ...6 HYDRAULIC SYSTEM 6 3 12 This Page Intentionally Left Blank...

Page 137: ...6 HYDRAULIC SYSTEM 6 3 14...

Page 138: ...6 HYDRAULIC SYSTEM 6 3 15...

Page 139: ...6 HYDRAULIC SYSTEM 6 3 16 This Page Intentionally Left Blank...

Page 141: ...6 HYDRAULIC SYSTEM 6 3 18...

Page 143: ...6 HYDRAULIC SYSTEM 6 3 20 This Page Intentionally Left Blank...

Page 145: ...6 HYDRAULIC SYSTEM 6 3 22...

Page 147: ...6 HYDRAULIC SYSTEM 6 3 24 This Page Intentionally Left Blank...

Page 149: ...6 HYDRAULIC SYSTEM 6 3 26...

Page 150: ...6 HYDRAULIC SYSTEM 6 3 27...

Page 151: ...6 HYDRAULIC SYSTEM 6 3 28 This Page Intentionally Left Blank...

Page 153: ...6 HYDRAULIC SYSTEM 6 3 30...

Page 155: ...6 HYDRAULIC SYSTEM 6 3 32 This Page Intentionally Left Blank...

Page 157: ...6 HYDRAULIC SYSTEM 6 3 34...

Page 159: ...6 HYDRAULIC SYSTEM 6 3 36 This Page Intentionally Left Blank...

Page 161: ...6 HYDRAULIC SYSTEM 6 3 38...

Page 162: ...6 HYDRAULIC SYSTEM 6 3 39...

Page 163: ...6 HYDRAULIC SYSTEM 6 3 40 This Page Intentionally Left Blank...

Page 165: ...6 HYDRAULIC SYSTEM 6 3 42...

Page 166: ...6 HYDRAULIC SYSTEM 6 3 43...

Page 168: ...6 HYDRAULIC SYSTEM 6 3 45...

Page 169: ...6 HYDRAULIC SYSTEM 6 3 46...

Page 219: ...6 HYDRAULIC SYSTEM 6 7 8 1 4 3 8 7 12 10 10 15 a b c Loctite 262 0 30Nm 0 45Nm...

Page 348: ...7 ADJUSTMENT AND REPAIR 7 5 31 6 Control Levers Pilot valves Control valve...

Page 349: ...7 ADJUSTMENT AND REPAIR 7 5 32 7 Upperstructure Implement Bucket cylinder Arm cylinder...

Page 351: ...7 ADJUSTMENT AND REPAIR 7 5 34 9 Undercarriage High speed travel solenoid valve...

Page 359: ......

Page 360: ...CHAPTER 8 PERIODIC INSPECTION AND SERVICING 8 1 List of Periodic Inspection and Servicing 8 1...

Page 361: ......

Page 364: ...CHAPTER 9 FUEL LUBE OIL AND GREASE RECOMMENDED 9 Fuel Lube Oil and Grease Recommended 9 1...

Page 365: ......

Page 367: ......

Page 369: ......

Page 406: ...CHAPTER 11 REFERENCE DATA 11 1 Specifications for Attachment 11 1...

Page 407: ......