144

6.1.7 Purging the fuel tank

DANGER

Keep all sparks, flames or cigarettes away.

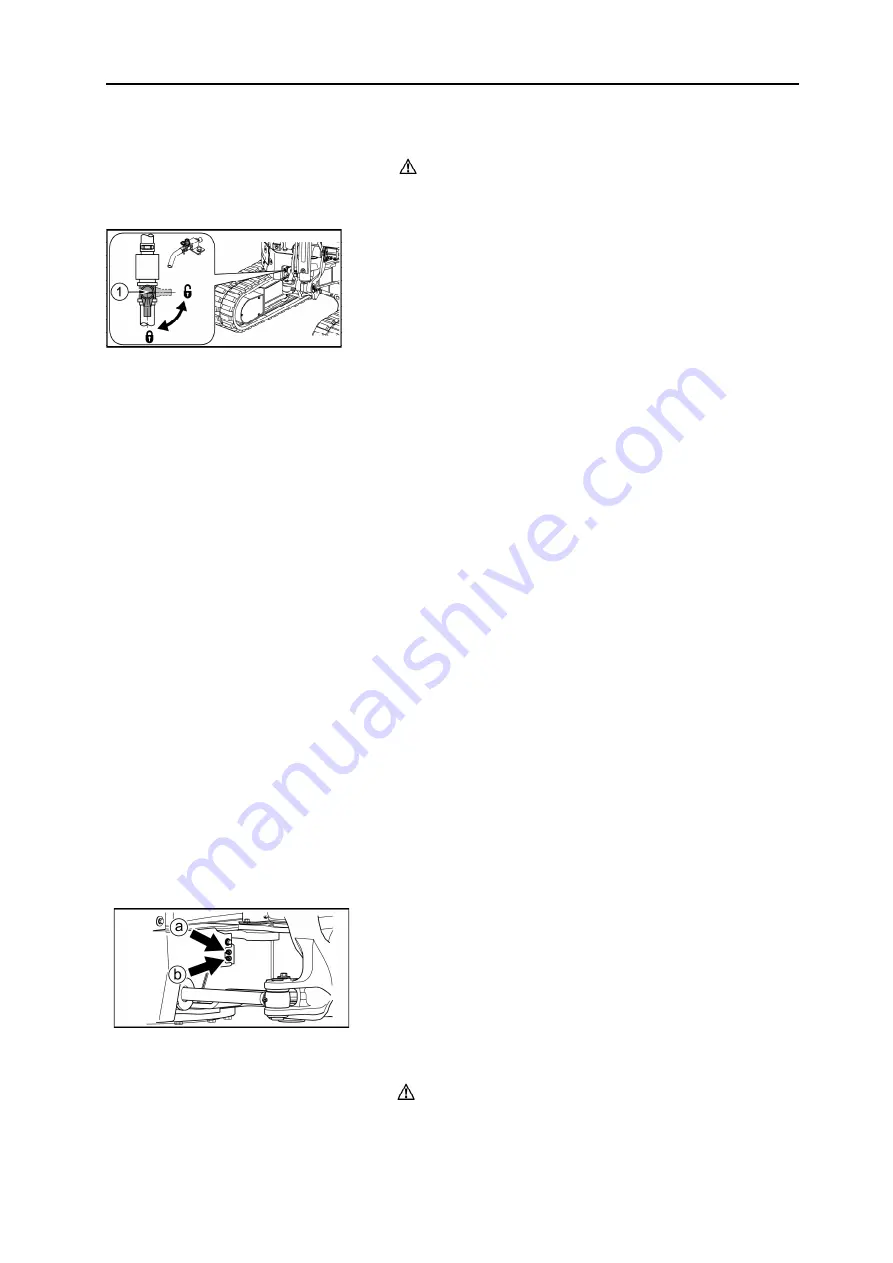

1 = Purge tap

1. Pivot the upper structure so that the drainage cap is

opposite the blade between the two tracks.

2. Place all the boom rotation cylinder to maximum

extension.

3. Remove the hose from its housing.

4. Place a container to catch the fuel residue under the

hose.

5. Open the tap to purge the water and dirt left in the

tank.

6. As soon as clean fuel starts coming out, close the

purge tap.

6.1.8 Checking the hydraulic hoses

• Visually check that there are no oil leaks from the hydraulic hose connectors.

6.1.9 Visual inspection of the fuel hoses

• Visually check that the fuel does not leak from the fuel hose connectors.

• Also check that the hoses are not damaged. If there are any faults, contact your dealer.

• The fuel hoses must be changed every 2 years or every 2000 hours of service. Contact your

dealer.

6.2 Maintenance every 50 hours

6.2.1 Greasing the pin and rotation crown

• Using a grease pump, grease the pin and the rota-

tion crown at the greasers indicated with arrows on

the figure opposite.

a = Rotation crown

b = Pin

• Slowly pivot the upper structure until it has made one complete turn.

WARNING

Do not pivot the upper structure during greasing. Grease and pivot alternately to avoid

any injury.

Summary of Contents for ViO38-6

Page 3: ......

Page 5: ......

Page 7: ......

Page 9: ......

Page 17: ......

Page 19: ...2 ...

Page 24: ...3 Warning labels 7 3 1 Location of the warning adhesive labels ...

Page 25: ...3 Warning labels 8 ...

Page 75: ...58 ...

Page 143: ...126 ...

Page 145: ...128 ...

Page 173: ...156 ...

Page 177: ...160 ...

Page 179: ...162 ...

Page 185: ...168 ...

Page 196: ...C Notes 179 ...

Page 201: ...MINI EXCAVATOR http www yanmar eu ...

Page 202: ...USER OPERATION AND MAINTENANCE MANUAL MINI EXCAVATOR ViO38 6 ...