X K 3 1 9 0

-

C 602

execute the procedure repeatedly.

4. If the remaining material weight is less than the min. weight (i.e.d1+d2) of one time

material feeding weight plus material in the hopper, the instrument will be stopped to do the

material feeding and wait for the Add Signal (it means material charging is allowed, that is, feed

material to the hopper); The output control signal of material discharging of the instrument will be

valid after there is an Add Signal and it will start to judge the weight. If the material weight in the

hopper is added to the weight confirmed by the parameter A2, the material discharging will be

stopped and the material feeding cycle which is just stopped will continue.

For example: the batching value of material 1 is 50 kg, the batching value of material 2 is

150kg and the min. remaining weight b2 is 20kg. If the remaining weight in the hopper is less than

70 kg when the cycle is started, the material should be added to the hopper up to over150kg to

start the material feeding.

Table 6-2 describes the working process of the quantitative scale subtraction by program step.

Display method of program step

Set Parameter 7B

【

SET 0

】

to 4; under the running status,

the auxiliary display of the instrument will show current program step number in the forms of

‘Step**’.

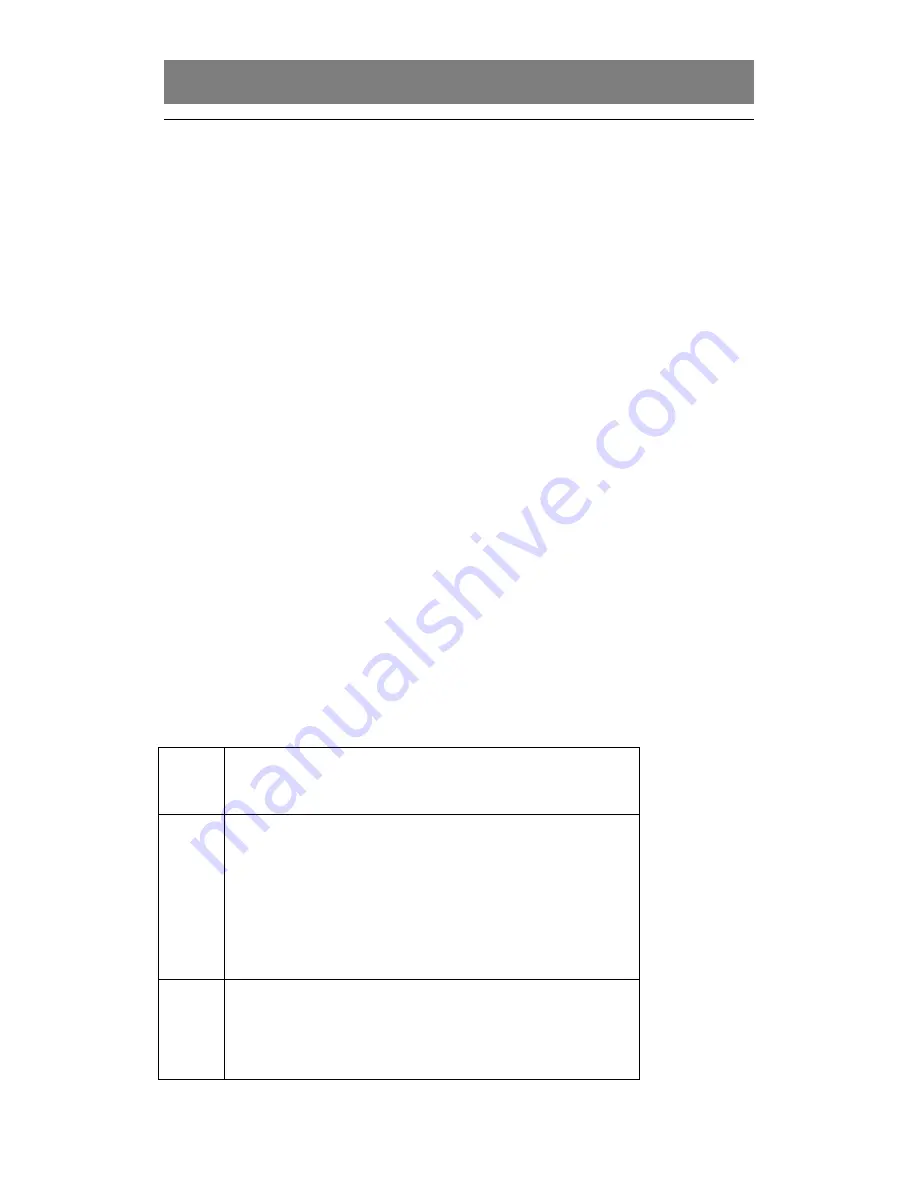

Table 6-2 Description of Program Step of Subtracting Quantitative Scale

Program

step

Description

1

If the hopper weight is less than the min. material weight plus

batching value, go to program step 13.

Wait for the stable display light to be ON and the Add Signal to be

valid, it will enter the status of negative scale, the timer will be T0

and go to program step 2.

2

Start the quick feed. If T1 is 0, start the slow feed at same time.

The timing T0 is over and weight inspection is started. If the

loaded value reaches to batching value minus quick feed lead, turn