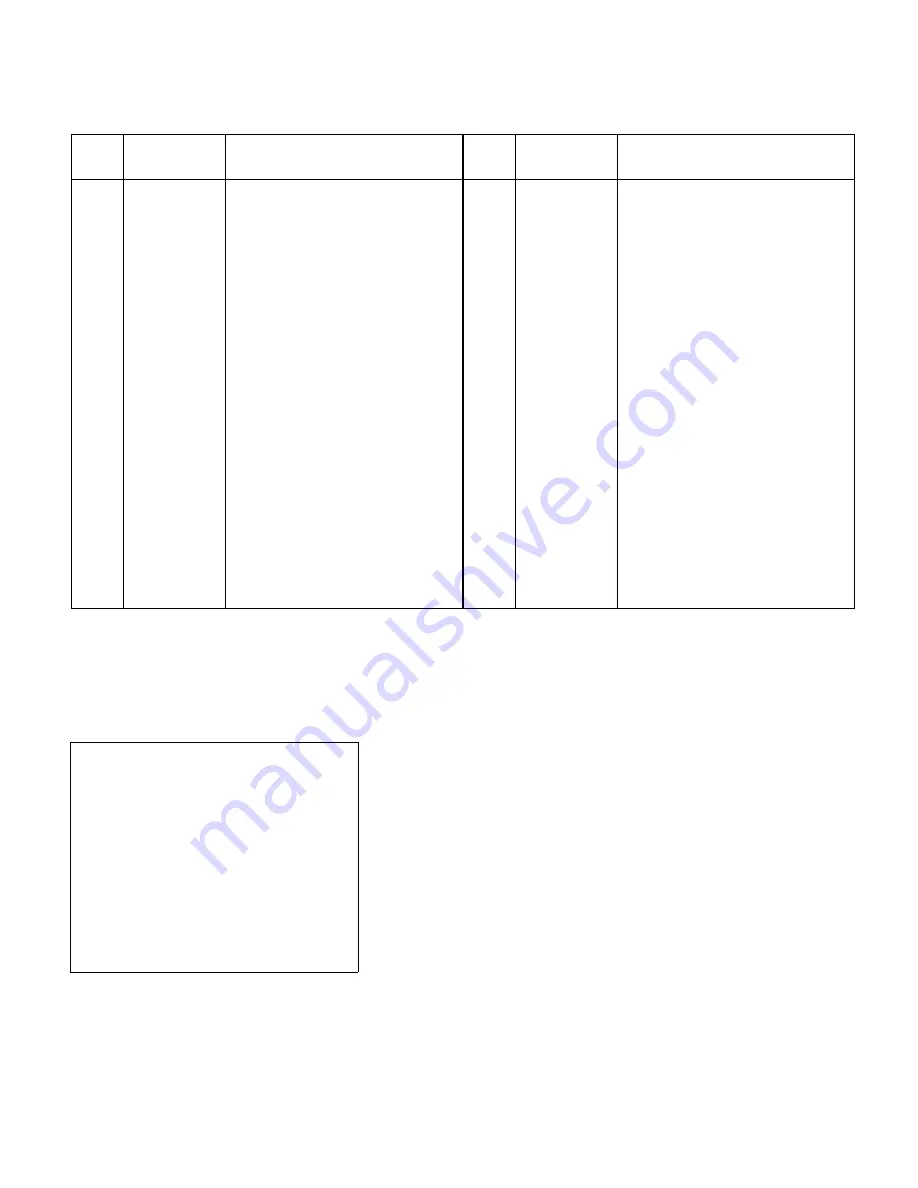

19

Model 203

Ref.

No.

Part No.

Part Description

1.

749-1095

Upper Handle

2.

1539-019

Push Nut

3.

711-0737

Stud Pin.250 x 1.75

4.

746-0714

Clutch Cable 56"

5.

731-1735

Upper Clutch Cover

6.

731-0620

Drive Lever

7.

731-1736

Lower Clutch Cover

8.

710-0841

Screw #10-12 x.750

9.

731-1059

Cable Mounting Cap

10.

710-1331

Screw #10-16 x 1.25

11.

710-0805

Hex Cap Screw 5/16-18 x 1.50

12.

736-0451

Shoulder Washer.320 ID x.93 OD

13.

712-3004A

Hex Flange Lock Nut 5/16-18

14.

725-0157

Cable Tie

15.

712-0380

Hex Nut 1/4-28

17.

781-0647

Discharge Chute Bracket

18.

710-3008

Hex Cap Screw 5/16-18 x.75

19.

747-0815

Eye Bolt

20.

710-0896

Self Tapp. Screw 1/4-14 x.625

21.

731-1646

Belt Cover

22.

719-0359

Engine Mounting Adapter

26.

710-3103

Hex Cap Screw 5/16-18 x 1.75

27.

749-1094

Lower Handle

28.

710-0502A

Screw 3/8-16 x 1.25

29.

710-0604A

Hex Washer Screw 5/16-18 x.625

30.

741-0413

Hex Flange Bearing.631 x.720

31.

681-0097A

Frame Assembly

32.

781-0700

Axle Bracket

33.

781-0697

Transmission Cover

34.

747-0924

Lock Pin

35.

732-0306

Compression Spring

36.

726-0214

Push Cap

37.

736-0366

Flat Washer 5/8 ID x 1.0 OD

38.

741-0487A

Flange Bearing.632 ID

39.

736-0264

Flat Washer.330 ID x.630 OD

40.

714-0104

Cotter Pin

41.

681-0087

Bracket Assembly

42.

737-3000

Grease Fitting 3/16

43.

736-0931

Flat Washer.203 ID x.403 OD

44.

681-0088

Bracket Assembly

45.

710-0521

Hex Cap Screw 3/8-16 x 3.0

46.

712-0431

Flange Lock Nut 3/8-16

47.

750-1042

Spacer

48.

734-1804A

Wheel 6.0 x 2.0

Ref.

No.

Part No.

Part Description

NOTE: For painted parts, please refer to

the list of color codes below. Please add

the applicable color code, wherever

needed, to the part number to order a

replacement part. For instance, if a part

numbered 700-xxxx is painted Yard-Man

Green, the part number to order would be

700-xxxx-0665.

Yard-Man Green: 0665

Yard-Man Yellow: 0674

Powder Black: 0637