8

•

Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope rewind

slowly.

•

Repeat the previous steps until engine fires. When

engine starts, move choke control (if equipped)

gradually to RUN position.

WARNING: Keep bystanders, helpers,

pets, and children at least 75 feet from the

machine before starting and while

operating. Do not operate this machine

unless the discharge chute and bag have

been properly installed and secured to the

machine.

Stopping Engine

•

Move throttle control lever to STOP or OFF

position.

•

Disconnect spark plug wire from spark plug and

ground against the engine.

To Empty Bag

The bag is designed to be emptied without being

removed from unit. Open the large zipper in the rear of

the bag to empty the contents. If bag is removed for any

reason, follow the instructions for attaching the bag in

the ASSEMBLY section. Be certain the zipper is closed

completely when operating the unit.

To Engage Drive

To engage the wheel drive, hold the drive clutch control

against the upper handle. Releasing the drive clutch

control stops the rear wheels from driving. Release the

drive clutch control to slow down when negotiating an

obstacle, making a turn, or stopping. Engage control

slowly to prevent the front wheels from lifting up.

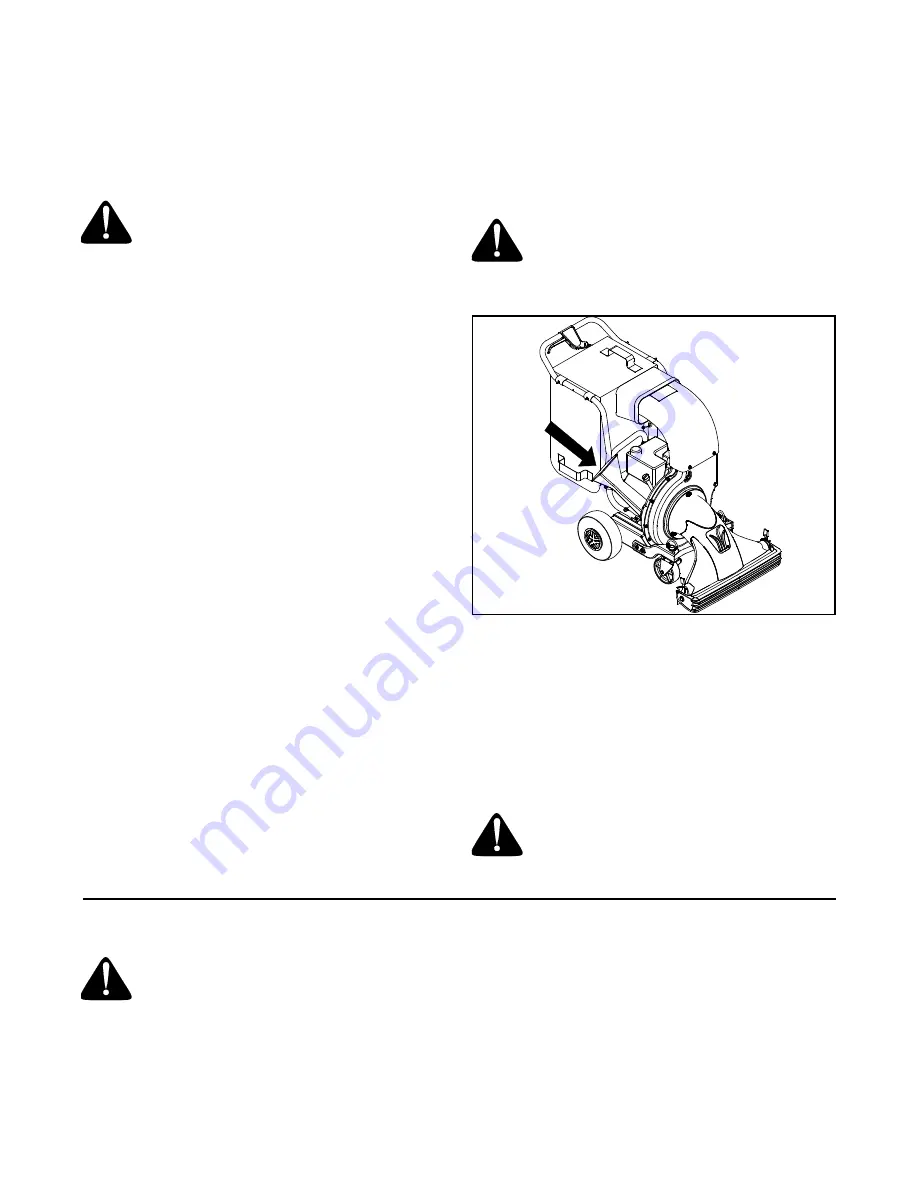

Using the Chipper Shredder Vacuum

Place both hands on top of upper handle to push unit

over yard waste. Yard waste such as leaves and pine

needles can be vacuumed up through the nozzle for

shredding. After material has been shredded by the

blades on the impeller assembly, it will be discharged

into catcher bag. Do not attempt to shred or chip any

material other than vegetation found in a normal yard

(i.e. branches, leaves, twigs, etc.) Avoid fibrous plants

such as tomato vines until they are thoroughly dried

out. Materials such as stalks or heavy branches up to 2”

in diameter may be fed into the chipper chute.See

Figure 6.

WARNING: Do not attempt to shred, chip,

or vacuum any material larger than

specified on the machine or in this

manual. Personal injury or damage to the

machine could result.

Figure 6

IMPORTANT:

The flail screen is located inside the

housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

MAINTAINING YOUR CHIPPER SHREDDER

VACUUM. For best performance, it is also important to

keep the chipper blade sharp.

Tire Pressure

(Pneumatic Tires Only)

WARNING: Maximum tire pressure under

any circumstance is 30 psi. Equal tire

pressure should be maintained at all

times.

SECTION 5: ADJUSTING YOUR CHIPPER SHREDDER VACUUM

WARNING: Do not at any time make any

adjustments without first stopping engine,

disconnecting spark plug wire, and

grounding it against the engine.

Front Caster Wheels

This chipper shredder vacuum is equipped with front

caster wheels. The casters can be locked in a straight

ahead position or position to swivel freely. Lift and place

pins in the larger holes for locked or straight ahead

operation. Place pins in smaller holes to allow casters

to rotate freely. Lock wheels in straight position when

operating on slopes. See Figure 7.

Chipper

Chute