9

Figure 7

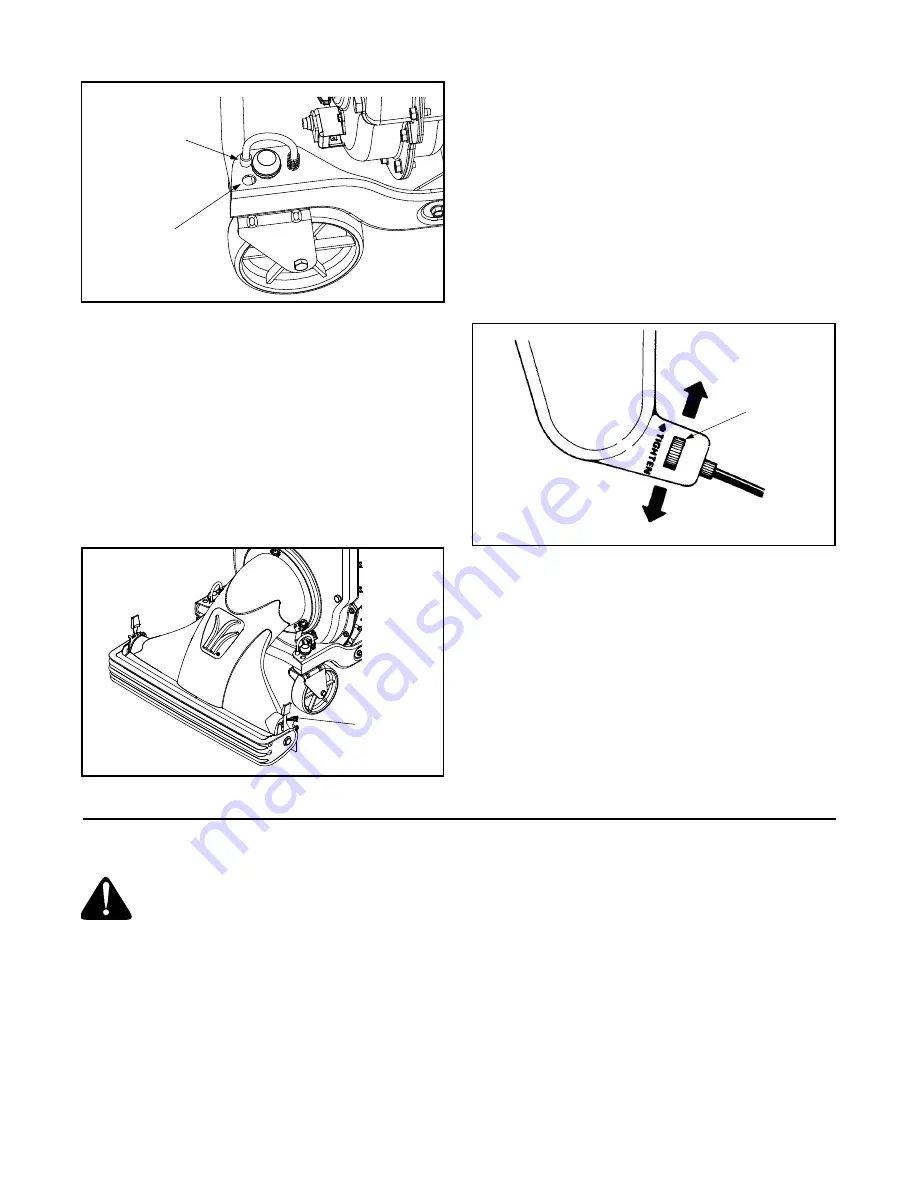

Nozzle Door Height Adjustment

The nozzle adjustment levers are located on each side

of the nozzle door. The nozzle door can be adjusted to

any of five positions, ranging from 1/2” to 3” ground

clearance that will provide the best performance for the

operating conditions. Slide the height adjustment lever

forward or backward for adjusting the nozzle door

upwards or downwards. Height must be adjusted

equally. In general, raise the nozzle to vacuum a thick

layer of leaves and lower the nozzle for smooth

surfaces. See Figure 8.

Figure 8

Drive Clutch Cable Adjustment

Adjust the drive clutch control if the chipper shredder

vacuum moves forward with the drive clutch control

disengaged, if it does not self-propel with the drive

clutch control engaged, or if drive belt is slipping (unit

hesitates while engine maintains the same speed). Use

the adjustment wheel located in the clutch control

housing to tighten or loosen the clutch cable. In

addition, the adjustment wheel may also be used to

determine the position in which the drive clutch control

is engaged. If it is more comfortable to have the drive

engaged with the lever further away from the handle,

tighten the clutch cable. See Figure 9.

Figure 9

Engine Adjustments

Refer to the separate engine manual for engine

adjustment instructions.

SECTION 6: MAINTAINING YOUR CHIPPER SHREDDER VACUUM

WARNING: Before performing any mainte-

nance or repairs, stop the engine, wait

until the machine comes to a complete

stop, disconnect the spark plug wire and

ground against the engine to prevent unin-

tended starting.

Lubrication

(Refer to Figure 5)

Wheels: Lubricate the rear wheels with light oil once a

season.

Nozzle Door Adjustment Levers: Lubricate each

adjustment lever once a season with light oil.

Front Caster Wheels: Grease fittings are located on

the front caster wheels to provide easy lubrication of the

swivel pins once a season.

Smaller Hole

(Rotate Freely)

Larger Hole

(Locked)

Nozzle Door

Adjustment

Lever

Tighten

Loosen

Adjustment

Wheel