6

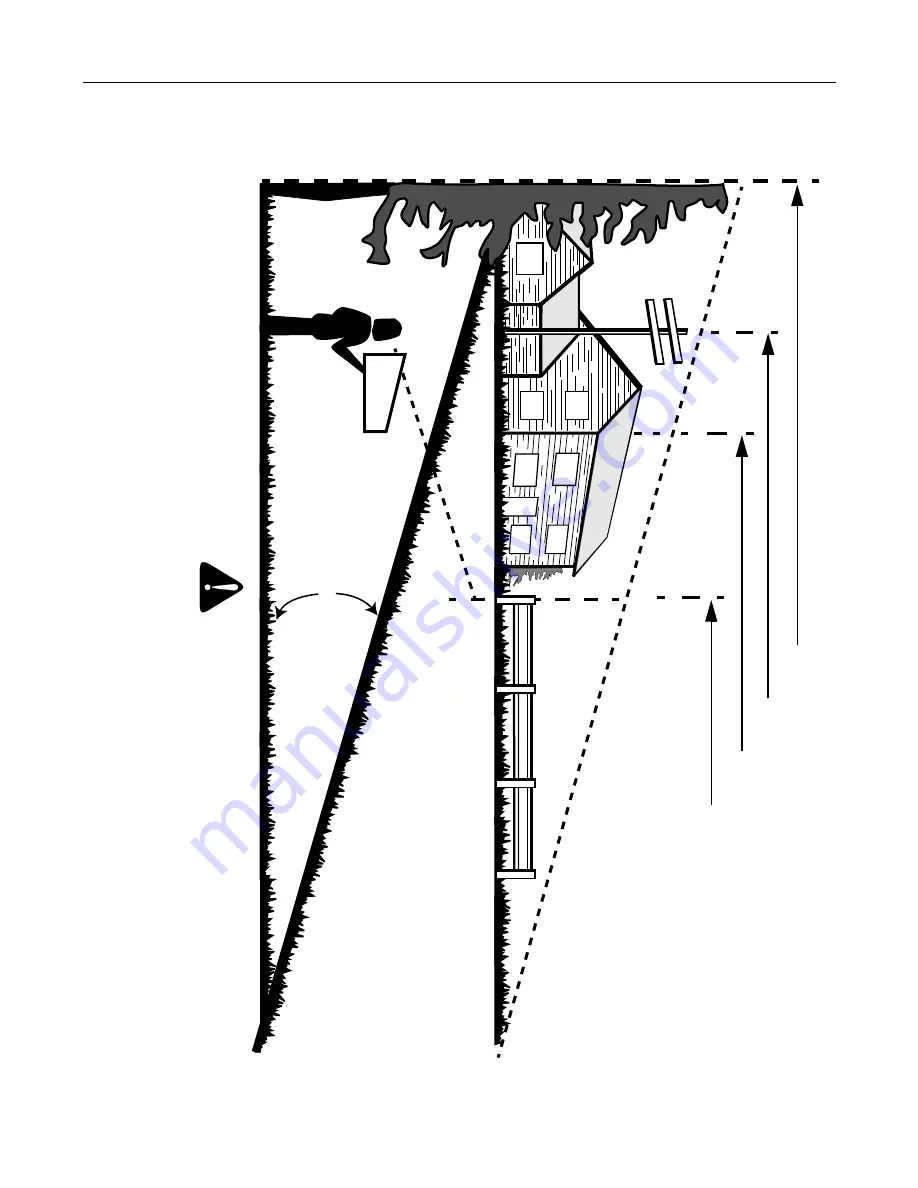

SECTION 2: SLOPE GAUGE

Use this page as a guide to determine slopes where you may not operate safely. Do not operate your lawn mower

on such slopes.

15

°

SIGHT AND HOLD THIS

LEV

E

L

WITH

A VERTI

CAL TREE

A POWER

POLE

A CORNER OF A BUILDING

OR

A FENCE POST

F

O

L

D

O

N

D

O

T

T

E

D

L

IN

E

, R

E

P

R

E

S

E

N

T

IN

G

A

1

5

° S

L

O

P

E

WARNING

Do

n

o

t mow on

in

cl

ines with

a

slo

pe in

e

x

ce

ss of

15 de

gr

ee

s (

a

ri

se of

ap

pr

oximat

ely 2-

1/

2 f

eet

ever

y

1

0

f

eet

). A ridi

ng mo

we

r could

ov

er

tu

rn

an

d ca

u

s

e

s

e

riou

s in

ju

ry

. If o

p

e

ra

tin

g a

walk

-b

eh

in

d m

o

w

e

r

o

n

s

u

c

h

a

s

lop

e,

it

is ext

re

m

ely

d

iffic

u

lt

to

m

a

in

ta

in

y

o

u

r f

oot

in

g

and you

could s

lip

,

result

ing in

s

e

rious injury

.

Operate

RIDING mow

e

rs up

and down s

lo

pes,

never

acro

ss th

e f

a

ce of

slo

pes.

Ope

ra

te

WALK-

BEHI

ND

mo

wers acro

ss t

he f

a

ce

of

slo

p

e

s

, neve

r up

a

nd do

wn slo

pes.