1

2

3

SPECIFIC SAFETY RULES

Thoroughly inspect the area to be tilled, and remove all debris

and hard or sharp objects such as stones, sticks, glass, wire, bones,

etc. Do not operate tiller in soil with large rocks and foreign

objects which can damage the machine.

Do not till above underground electric cables, telephone lines,

water lines, gas lines, pipes, or hoses. If in doubt, contact your

utility or telephone company to locate underground services.

Keep all bystanders, children, and pets at least 75 feet (23m)

away. If you are approached, stop the unit immediately.

This unit has a clutch. Squeeze the drive control handle lever and

check that it returns automatically to the neutral position. If it

does not, have unit adjusted by a qualified repair personnel.

Disengage drive control handle lever before starting the engine.

Start the engine carefully according to instructions and with feet

well away from the tines.

The tines remain stationary when the clutch is disengaged. If it

does not, have unit adjusted by a qualified repair personnel.

Always operate the machine from behind, never pass or stand in

front of the machine when the engine is running.

Always hold the unit with both hands when operating. Keep a firm

grip on the grips. Be aware that the machine may unexpectedly

bounce upward or jump forward if the tines should strike buried

obstacles such as large stones, roots, or stumps.

If the unit strikes a foreign object, stop the engine, disconnect the

spark plug, thoroughly inspect the machine for any damage, and

repair the damage before restarting and operating the machine.

Use extreme caution when in reverse or pulling the machine

towards you.

Do not overload the machine capacity by tilling too deep in a

single pass or at too fast a rate.

never operate the tiller at high transport speeds on hard or

slippery surfaces.

be careful when tilling in hard ground. The tines may catch in the

ground and propel the tiller forward. If this occurs, let go of the

handlebars and do not restrain the machine.

Use caution when tilling near fences, buildings and underground

utilities. Rotating tines can cause property damage or personal

injury.

Exercise extreme caution when operating on or crossing gravel

drives, walks, or roads. Stay alert for hidden hazards or traffic. Do

not carry passengers.

never leave the operating position when the engine is running.

Always stop the engine when tilling is delayed or when walking

from one tilling location to another.

Keep unit clean of vegetation and other materials. They

may become lodged between the tines. Stop the engine and

disconnect the spark plug before unclogging the tines.

To reduce exposure to vibration, limit the hours of operation

and take periodic breaks to minimize repetition and rest your

hands. Reduce the speed and force in which you do the repetitive

movement. Try to fill each day with jobs where operating hand-

held power equipment is not required.

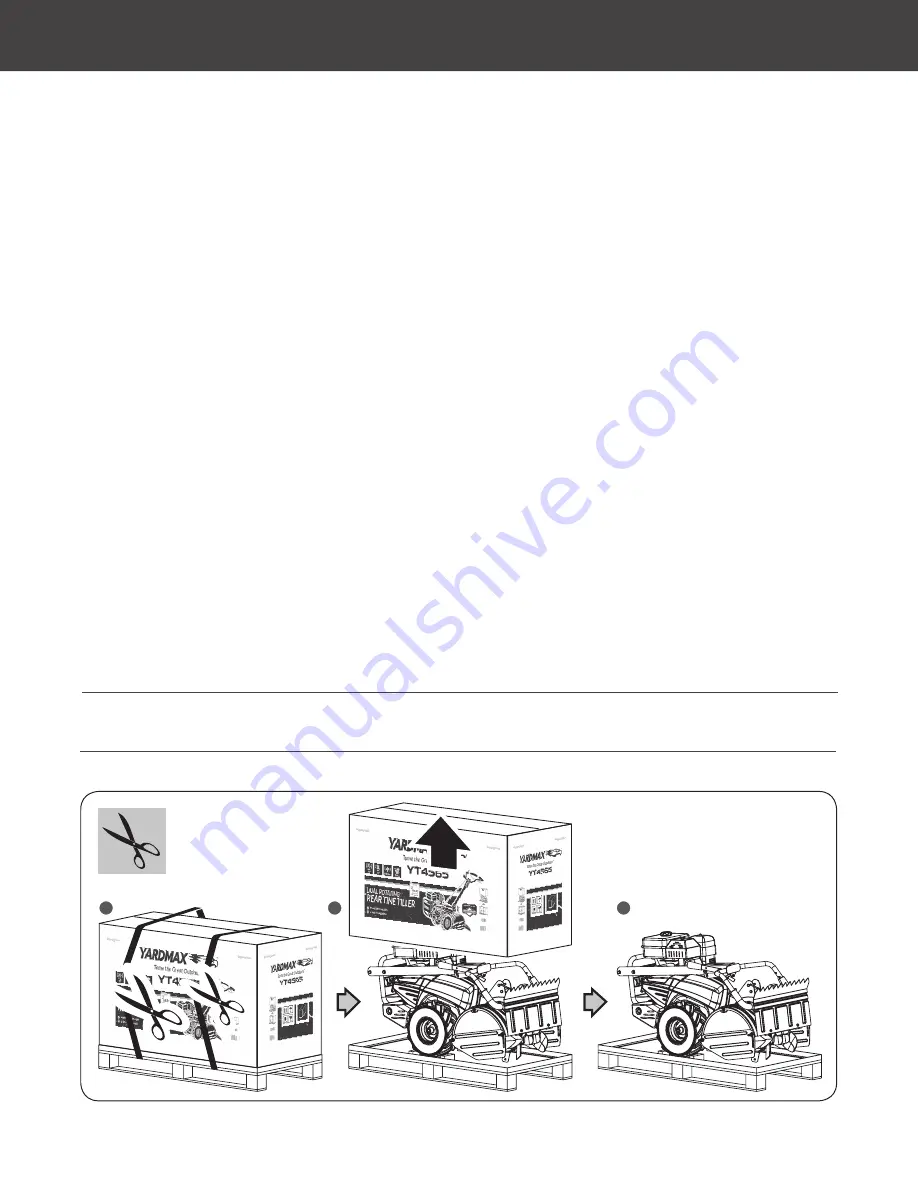

UnPACKInG THE COnTAInER

Figure 1

Use scissors or a knife to cut all the straps. lift off the carton and dispose of properly. (See

Figure 1

)

6

Dual Rotating Rear Tine Tiller

»

Operator’s Manual

YT4565PM02 - 1704

Unpacking the Container

|

32850US25M102.indd 6

2017/3/27 10:22:00