+

TRANSPORTING

MOVING BY HANDS

�

The log splitter

is

heavy. It can crush and cause

Lil

serious injury if it rolls out of control or tips over.

Follow the instructions below

for

safely moving the log splitter.

1.

Make

sure the log splitter is locked in the horizontal position

with latch rod

before

moving.

� Make sure the log splitter engine

is

off, Never move

Lil

the log splitter with its engine running.

2. Turn the fuel shut-off

valve

to the OFF position. This prevents

carburetor flooding and reduces the chance of fuel leakage.

Refer to the engine manual

for

fuel

valve

location.

3. Lock the support leg in the DOWN position

before

you

move

the log splitter.

4.

Move

the log splitter by hand to desired work site.

&

Do not move the log splitter up or down hills by hand.

&

Never allow anyone to sit or ride on the log splitter.

&

Never transport cargo or wood on the log splitter.

TOWING BY VEHICLE

1. Turn the fuel shut-off

valve

off.

This prevents fuel

from

flooding

the engine.

2. Check the tires to ensure they

are

fully inflated to 30 PSI

for

proper functionality.

� Do not overinflate tires. Serious injury can occur if

Lll

tire explodes.

�

When seating a bead after repair, do not exceed 30

Lil

PSI. Pressures higher than 30 PSI can cause the tire

and wheel to rupture and explode.

21

I Transporting

65916US25M104_GB.indd 21

3. Make sure hitch is in good working

order.

4. Check safety chains. Two safety chains must be used while

towing.

Cross

safety chains under the coupler, allowing only

enough slack

for

vehicle turns.

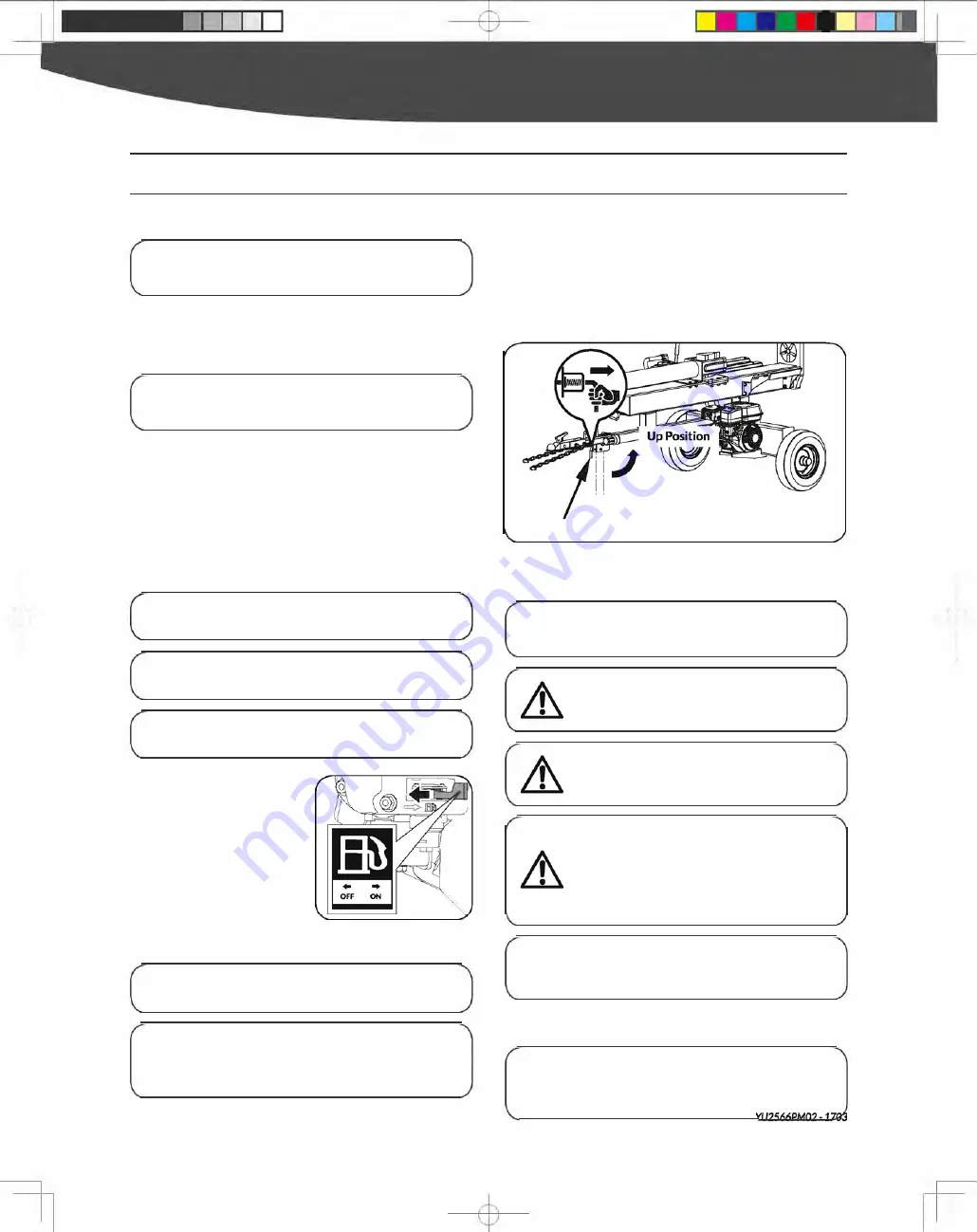

5. Pull out the lock

lever

and put the support leg in the UP position,

then release the

lever

and make sure the leg is secured.

l.L

Down Position

Support Leg lock

Figure 13

6. Tow the log splitter carefully to desired work site.

&

Be aware of the added length of the splitter.

Never tow this log splitter over

45

mph. Faster

speeds may result in loss of control.

Drive slowly and take extra caution when traveling

over rough terrain.

If towing on a public road, make sure to comply with

all local, state, and federal towing requirements. It

is the sole responsibility of the purchaser to obtain

licensing, trailer lights, safety chains, or signage as

needed to comply.

�

Turn off the towing vehicle before leaving the splitter

Lil

unattended.

7. Lock the support leg in the

DOWN

position and disconnect

from

vehicle.

� Never operate the log splitter while it is attached to

Lil

the vehicle.

2020/3/27 14:09:04

+