model no.

060-2385-8

| contact us: 1.866.523.5218

model no.

060-2385-8

| contact us: 1.866.523.5218

41

PARTS

LIS

T–

C

(PRODUC

T)

Item

Description

Drawing

QTY.

1

Starter Assembly

F28.0210.0000

1

2

Start Housing Decorative Board

F28.0210.0001

1

3

Screw M5 x 20

01.01.6201

3

4

Start Housing

F28.0210.0100

1

5

Eyelet

YD25.02.01-2

1

6

Start Rope

YD25.02.00-5

1

7

Start Grip

YD62.02.00-3

1

8

Coil Spring

YD42.06-6

1

9

Coil Spring Cover

YD42.06-7

1

10

Start Pulley

F28.0110.0009

1

11

Start Torsional Spring

F28.0110.0002

1

12

Start Ratchet

F28.0110.0001

1

13

Start Dial Claw

F28.0110.0003

2

14

Plate Washer

F28.0110.0004

1

15

Circlip

F28.0110.0005

1

16

Rubber Pad

F28.0110.0008

1

17

Muffler Cover

F28.0110.0006

1

18

Screw ST4 × 10

01.01.3131

5

19

Air Deflector

F28.0210.0002

1

20

Flange Nut M8

01.01.0073

1

21

Magneto Rotor

F28.0106.0100

1

22

Key 3 x 5 x 13

A45.0101.0036

1

23

Screw M4 x 20

01.01.6208

2

24

Ignition

F28.0106.0200

1

25

Spark Plug Cover

F28.0106.0201

1

26

Heat Insulation Pad, Stator

F28.0101.0005

2

27

Screw M5 x 60

01.01.6234

2

28

Muffler Insulation Cover

F28.0101.0004

1

29

Muffler

F28.0105.0000

1

30

Muffler Gasket

F28.0101.0003

1

31

Spark Plug RCJ7Y

A45.0106.0500-2

1

Summary of Contents for 060-2385-8

Page 34: ...model no 060 2385 8 contact us 1 866 523 5218 34 EXPLODED VIEW A PRODUCT...

Page 36: ...model no 060 2385 8 contact us 1 866 523 5218 36 EXPLODED VIEW B PRODUCT...

Page 39: ...model no 060 2385 8 contact us 1 866 523 5218 39 This page intentionally left blank...

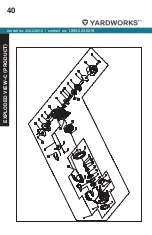

Page 40: ...model no 060 2385 8 contact us 1 866 523 5218 40 EXPLODED VIEW C PRODUCT...