84

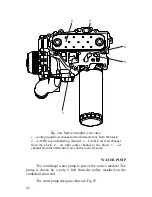

installed in the aluminum water pump housing

6

. The bearing is

closed and filled with grease.

On the pump drive spindle the end seal

9

is mounted and the

impeller

5

and the pulley

7

are press-fitted.

To ensure leak proofness of the end seal, the pump housing has

a drain hole

10

.

Installed on the suction cavity

2

is the cooling liquid feed pipe

from the vehicle radiator

1

.

From the volute cooling liquid comes to the L/O HE cavity

through the channel in the service module housing.

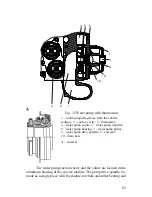

LIQUID-TO-OIL HEAT EXCHANGER

The liquid-to-oil heat exchanger (L/O HE) is used to maintain

optimal level of the oil temperature in the engine lubrication system.

The plate-type heat exchanger with one heat-transferring

element is part of the service module.

The plate-type heat-transferring element

2

(Fig.

26) with seven

plates is fixed onto the service module housing with four bolts

3

and

sealed against oil and cooling water leakage with a gasket

5

.

Summary of Contents for YMZ-536

Page 14: ...14 Fig 1 YMZ 536 engine right side view ...

Page 15: ...15 Fig 1 a YMZ 536 engine left side view ...

Page 16: ...16 Fig 1 b YMZ 536 10 engine right side view ...

Page 17: ...17 Fig 1 c YMZ 536 10 engine left side view ...

Page 18: ...18 Fig 1 d YMZ 536 30 engine right side view ...

Page 19: ...19 Fig 1 e YMZ 536 30 engine left side view ...

Page 20: ...20 Fig 1 f YMZ 5362 engine right side view ...

Page 21: ...21 Fig 1 g YMZ 5362 engine left side view ...

Page 22: ...22 Fig 1 h YMZ 53602 engine right side view ...

Page 23: ...23 Fig 1 i YMZ 53602 engine left side view ...

Page 51: ...51 Fig 10 Longitudinal section ...

Page 52: ...52 This page intentionally left blank ...

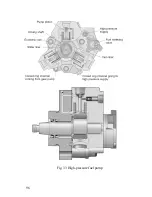

Page 96: ...96 Fig 33 High pressure fuel pump ...

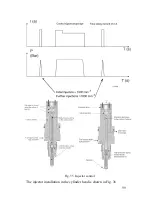

Page 99: ...99 Fig 35 Injector control The injector installation in the cylinder head is shown in Fig 36 ...

Page 168: ...168 NOTES ...