Corrosion, oil and other impurities in the joints are not permitted.

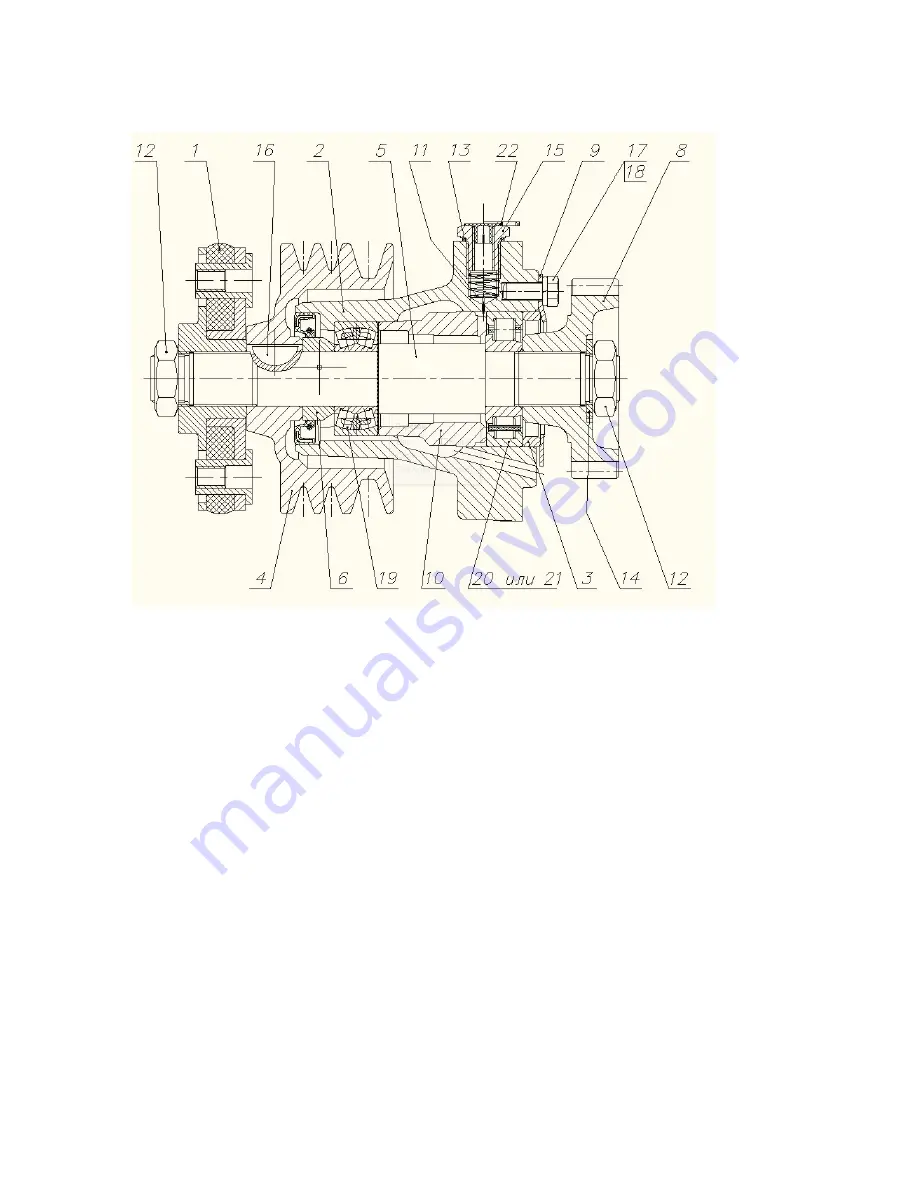

Picture 4.13 –

Fan drive 236НЕ-1308011-И

1- 236-1308090-

В2- flexible coupling; 2- 236НЕ-1308100 - body; 3- 236-1029034-thrust washer;

4- 236-1308025-

В2 - pulley; 5 - 236НЕ-1308050-Д - shaft; 6- 236-1308055-Б2 - collar of the

bushing; 8 - 236-1308104-

В - gear; 9 - 236-1308107-А - thrust flange;

10-

236НЕ-1308514-А2 - bushing; 11 - 236НЕ-1308780- throttle; 12- 311401-П29 -nut М22; 13

- 312367-

П - washer; 14-312490-П2 - washer 22; 15-316603-П29 - screw cap;16 - cotter 6for9; 17

- 201456-

П29 - bolt М8; 18 - 52135-П2 - washer 8Т; 19 - 8.8402 - bearing ; 20 - 8.8624 - bearing

; 21-8.8984- bearing ; 22- 8.8632 -

plug КЭМ

4.14.3 Gripping of the part should be performed with micrometer:

- position 12 from 206 (21) to 255 (26) Nwm (kgf m);

- position 15 from 38.24 (4.0) to 45.5 (5.0) Nwm (kgf m);

- position 17 from 13.7 (1.4) to 17.6 (1.8) Nwm (kgf m);

Technical requirements for the tightening according to the OST 37.001.031-72.

4.14.4 Inspection of the micrometer of the part tightening of the position 12 and 15 should be

performed no later than

900 (15) sec (min) from the moment of their installation.

4.14.5 Shaft should rotate free without constraints.

Summary of Contents for ???-236

Page 25: ...26...

Page 26: ...27 2...

Page 40: ......

Page 41: ......

Page 53: ......

Page 56: ......

Page 59: ......

Page 64: ...236 238 1003014 3 236 238 1003014 4 236 238 1003014...

Page 65: ......

Page 70: ......

Page 73: ......

Page 81: ......

Page 85: ......

Page 92: ......

Page 95: ......

Page 101: ......

Page 113: ......

Page 119: ......

Page 122: ......

Page 125: ......

Page 128: ......

Page 142: ......

Page 144: ......

Page 150: ......

Page 155: ......

Page 158: ......

Page 160: ......

Page 165: ......

Page 193: ...N u M a r Method defect detection and Dimension and parameter mm...

Page 201: ...4 Thread stripping M16 1 5 6H no more than two threads Inspection To calibrate the thread...