N

um

be

r of

the

d

ef

ect

L

oc

at

ion o

f

th

e p

ic

tu

re

Possible defect

Way for defect

detection and means

of control

Dimension and parameter, mm

Conclusion

nominal

maximum allowable

without repair

for repair

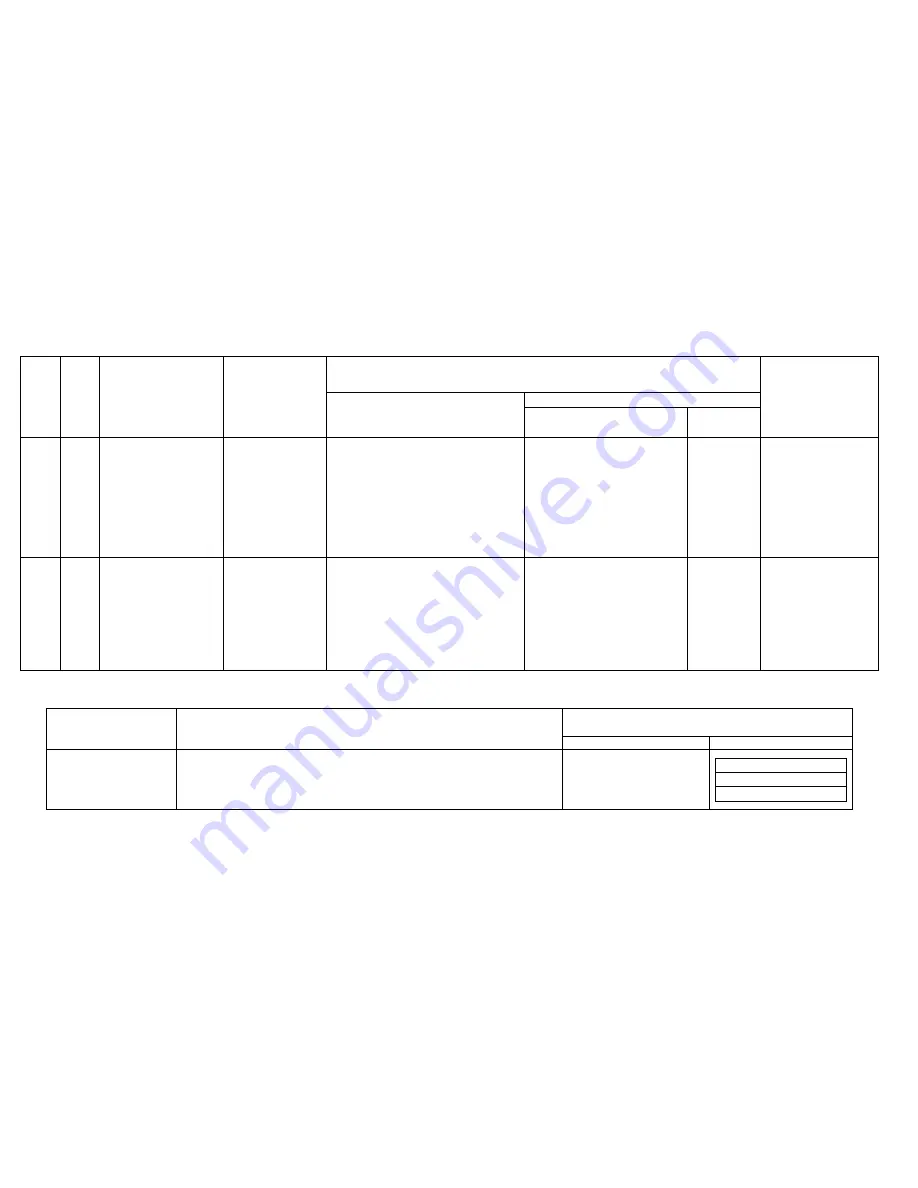

3

В

Wear or scuffing on the

internal surface of the

cylinder liner

Inspection.

Inside gauge

НИ100-160-1

See the table

3

-

-

To reject

4

А

Handling or compression

marks on the backing

ledge

Inspection.

Magnifier ЛП-1-4х

-

-

Scuffing

is not

allowed

To process the

bearing surfaces for

the elimination of the

defect within the

nominal

dimension of the

backing ledge

Table 3 – Dimensional grades of the cylinder liner according to the inside diameter

Number

of the defect

Name of the dimension

Repair dimensions, mm

1

2

3

Inside diameter of the cylinder liner

from 130.00 to 130.02

from 130.02 to 130.04

from 130.04 to 130.06

A

Б

Ж

Technical requirements for the repaired part

Number of the defect

1

Circular runout tolerance of the surface B relatively to the holeБ 0.7 mm

-----------------------------------------------------------

2

Summary of Contents for ???-236

Page 25: ...26...

Page 26: ...27 2...

Page 40: ......

Page 41: ......

Page 53: ......

Page 56: ......

Page 59: ......

Page 64: ...236 238 1003014 3 236 238 1003014 4 236 238 1003014...

Page 65: ......

Page 70: ......

Page 73: ......

Page 81: ......

Page 85: ......

Page 92: ......

Page 95: ......

Page 101: ......

Page 113: ......

Page 119: ......

Page 122: ......

Page 125: ......

Page 128: ......

Page 142: ......

Page 144: ......

Page 150: ......

Page 155: ......

Page 158: ......

Page 160: ......

Page 165: ......

Page 193: ...N u M a r Method defect detection and Dimension and parameter mm...

Page 201: ...4 Thread stripping M16 1 5 6H no more than two threads Inspection To calibrate the thread...