12.2 Application

12-17

12.2 Application

This section describes the application operation of digital operator in order to operate and adjust

the motor.

Read the section 12.1 "Basic operation" first.

You can set the user constant for application operation on the "Auxiliary function execution

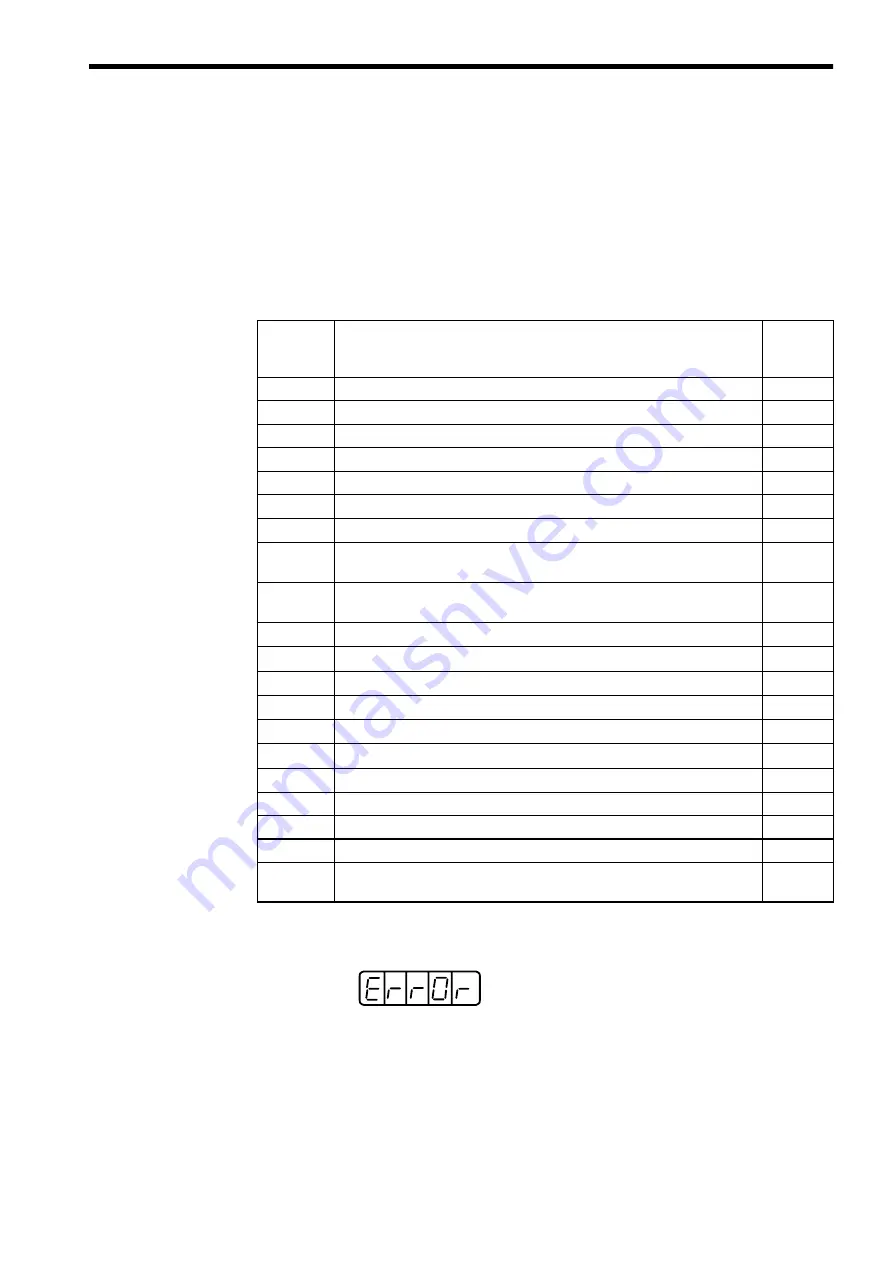

mode". The following table lists the user constants for auxiliary function execution mode.

Note: The user constants with a "

○

" mark and the user constants beginning

with "Pn" which have been set a password by Fn 010 are displayed as

followings. These user constants can not be changed.

User

constant

number

Function

Remarks

Fn000

Display of alarm trace back data

Fn001

Rigid setting at the time of on-line auto-tuning

○

Fn002

Reserved constant (no accessing)

Fn003

Origin searching mode

Fn004

(reserved constant)

Fn005

Initiation of user constant setting value

○

Fn006

Clear of alarm trace back data

○

Fn007

Inertia ratio from the result of on-line auto-tuning action

Write into EEPROM

○

Fn008

Multi return reset of absolute value encoder (setup operation)

and Alarm reset of encoder

○

Fn009

Reserved constant (no accessing)

○

Fn00A

Reserved constant (no accessing)

○

Fn00B

Reserved constant (no accessing)

○

Fn00C

Adjustment of analogue monitor output manual zero

○

Fn00D

Adjustment of analogue monitor output manual gain

○

Fn00E

Automatic adjustment of motor current detection signal offset

○

Fn00F

Manual adjustment of motor current detection signal offset

○

Fn010

Password setting (User constant rewrite prohibit)

Fn011

Check of motor type

Fn012

Indication of SERVOPACK soft ware version

Fn013

Setting changing of multi-return limit value at the time of the alarm "Multi-

return limit value mismatch (A.CC)" output

○

Flashes a

second.

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...