Safety precautions

xx

■

Operating

• Do not touch live units or terminals.

Otherwise electric shock or malfunction could result.

• Do not touch any current-carrying parts even if you have shut off power to

them, until at least 5 minutes have passed (to let any residual charge go

out).

Otherwise electric shock or malfunction could result.

• Take care not to damage, pull on, or pinch the cables.

Otherwise electric shock could result.

• Do not touch any rotating parts before you shut off power to them.

Otherwise injury could result.

• Never attempt to modify the product.

Otherwise electric shock, a fire, or damage could result.

• Close the upper and lower covers before switching on the input power.

Otherwise electric shock could result.

• Provide an additional emergency stop button outside the product.

This is a necessary safety precaution.

• Ensure that the environmental requirements are fully met.

A fire, electric shock, or malfunction could result if the product were operated in

excessively hot, humid, dusty, corrosive, vibration-, or shock-ridden conditions.

The environmental requirements are these:

• The atmosphere must be free of corrosive gas or vapor.

• There must be no risk of being splashed with machining oil or organic solvent.

• The relative humidity must be between 10 and 90%RH with no dew.

• The ambient temperature around the control panels must be between 5 and

30

℃

. The control panels must be protected from freezing, direct sunlight, heat

sources, or the elements.

• Floor vibration must not be more than 4.9 m/s

2

.

• Take care so that no wire chips or other foreign matter would enter the

product.

Otherwise a fire, damage, or malfunction could result.

• When using the programming functions, always follow the instructions

given in the relevant manuals.

Otherwise injury or malfunction could result.

WARNING

CAUTION

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

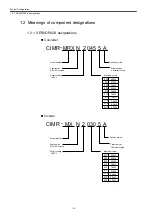

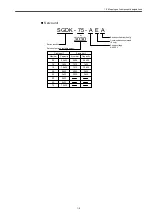

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...