14.1 Fundamental settings

14-23

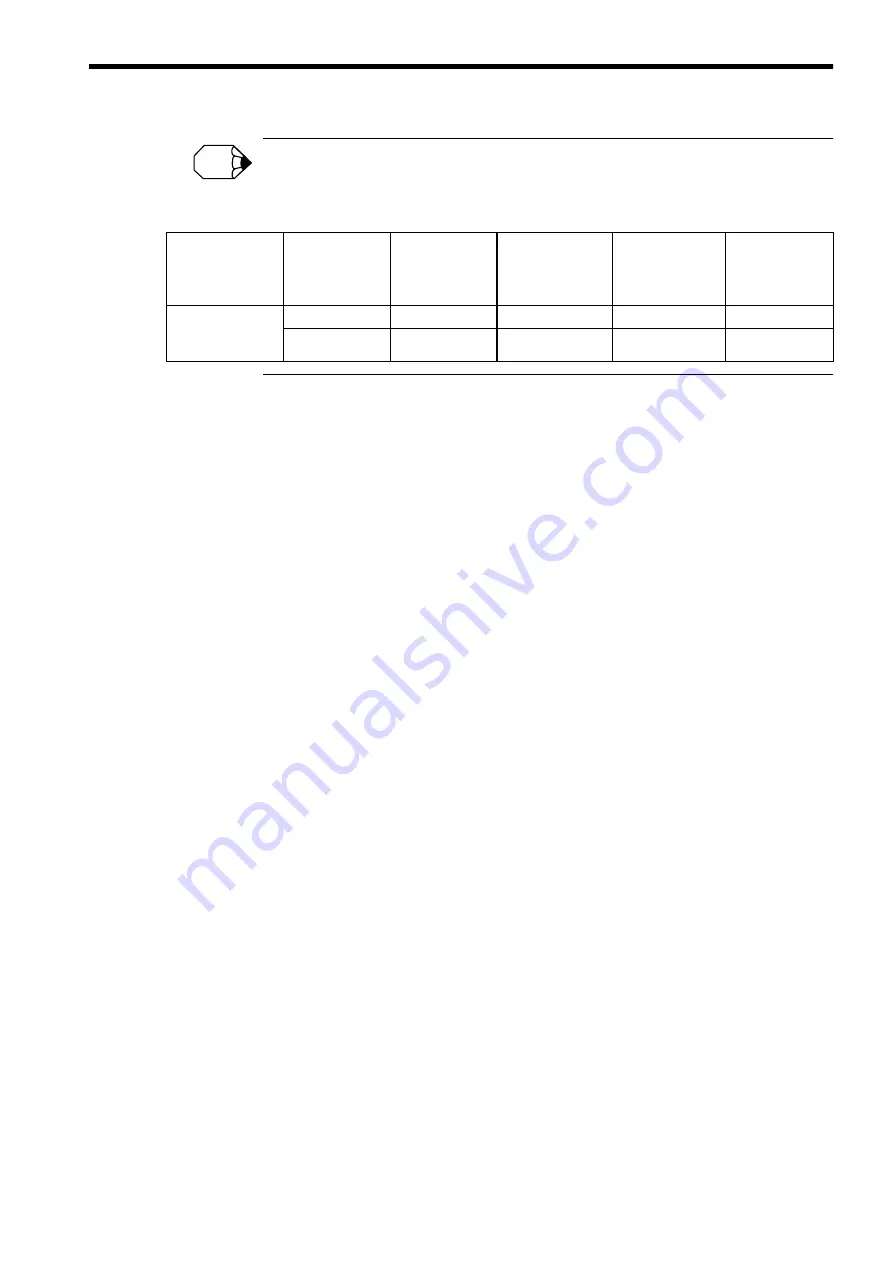

When a External encoder is connected for reverse rotation

MD32100 (Motor encoder rotation direction), MD32110 (External encoder rotation direction), and

MD3002 digit 3 (External encoder rotation direction) are to be set as follows.

• MD3006 digit 2 (Pn006 digit 2) FUNCTION_SWITCH_APPLIC6 (For each axis)

Meaning: Full-closed

specification

Setting value: 0 --- Type 2 (Internal drive position feed-back is used as External encoder

pulse.)

1 --- Type 1 (Internal drive position feed-back is used as motor encoder

pulse.)

Standard setting value: 0

• MD3205 (Pn205) MULTI_TURN_LIMIT

Meaning:

Multi-turn limit setting

Setting value: Multi-turn limit setting of absolute motor encoder

When Mitsubishi Heavy Industries MP scale is used, assign a number, 1

less than the gear ratio between motor encoder and MP scale.

Note: If Servo drive alarm "204 (A.CC)" is displayed as a result of this

parameter setting, release it using Fn013 operation from the Digital

operator. (See INFO "

■

When multi-turn limit value inconsistency

happens" in 14.1.5.)

Since the Fn013 operation cannot be made to a 20-bit absolute

encoder, you cannot use a 20-bit absolute encoder in combination

with the MP scale.

• MD3207 digit 3 (Pn207 digit 3) SWITCH_POSITION_REF (For each axis)

Meaning:

External PG type selection

Setting value: 0 --- Pulse encoder (Linear scale)

1 --- Pulse encoder (Rotary scale)

3 --- Mitsubishi Heavy Industries MP scale

Note: Be sure to assign "3" when an MP scale is used.

• MD3210 (Pn20A) PG_PLS_MTRRND_LW_FULLCLOSED (For each axis)

Meaning:

The number of full-closed PG pulses/Single revolution of motor (Lower

word)

Setting value: [Pulse]

INFO

External encoder

specification

Motor encoder

connection

Motor rotation

direction

MD32100

External encoder

rotation direction

MD32110

Motor rotation

encoder

MD3000 digit 0

External

encoder rotation

direction

MD3002 digit 3

Type 2 reverse

rotation

connection

Forward rotation

1

1

0

4 or 8

Reverse rotation

-1

1

0

2 or 6

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...