14.3 Motion Control

14-83

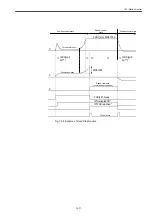

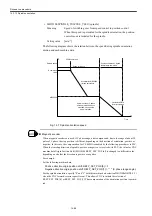

14.3.11 Collision detection

Collision detection function detects the collision of feed axes with the disturbance observer

and enables the pullback-stop of the torque reference. You can individually specify the

torque disturbance detection level of collision detection for each of

• positioning feed

• feed other than positioning feed, and

• forced input signal.

Also, it is possible to disable the collision detection function by the external input . With this

function, a series of events from the collision detection to the stop are processed with the

servo drive. The machine data and parameters related to the collision detection function are

listed below.

For the detailed information about adjustment procedure for the collision detection function,

see the separate explanation.

Collision detection function is not available for spindles.

CNC setting

Feed axes

• MD37610 PROFIBUS_CTRL_CONFIG (For each axis)

Meaning:

CNC feed mode to the drive

This machine data permits the switching over the disturbance detection

level from the positioning feed to the other feed and vise versa.

Setting value: 0---disabled

1---enabled

You must specify 1 (enabled) when the collision detection function is

enabled.

Drive setting

• MD3063 (Pn121) GAIN_DISTURB_OBSERVER (For each servo axis)

Meaning:

Disturbance observer gain

Setting value: [Hz]

• MD3064 (Pn122) HPF_CUT_FREQ_DISTURB_OBSRVR (For each servo axis)

Meaning:

Disturbance observer high pass filter cutoff frequency

Setting value: [Hz]

• MD3066 (Pn124) LPF_CUT_FREQ_DISTURB_OBSRVR (For each servo axis)

Meaning:

Disturbance observer low pass filter cutoff frequency

Setting value: [Hz]

IMPORTANT

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...