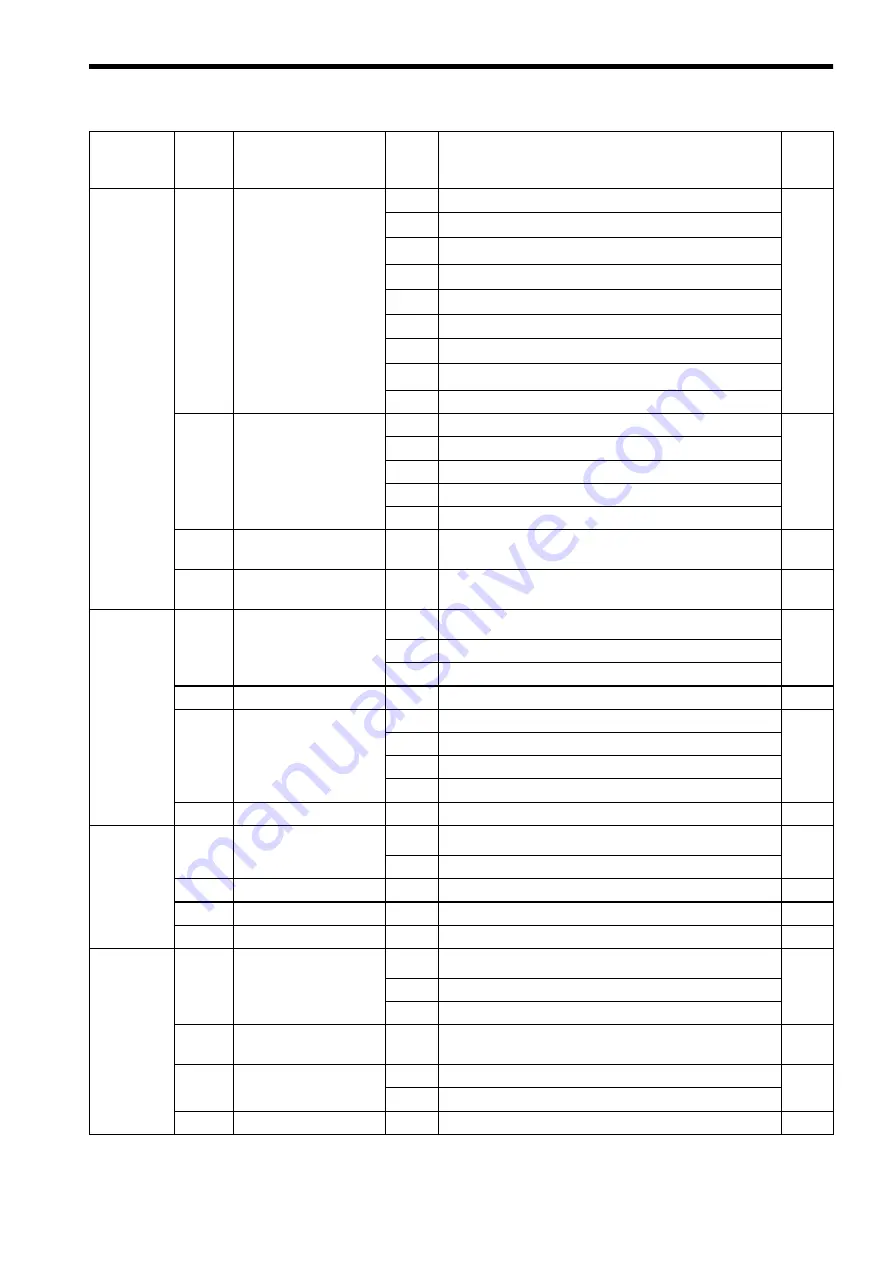

Appendix A Parameters

A-9

MD3003

(Pn003)

Applied

function

selection

(Continued)

0

Analogue monitor 1

selection

7

Collision detection amount :1V

/

100

%

2

8

Quadrant error compensation amount :1V

/

100

%

9

Speed feed forward :1V

/

100 min

-1

A

Torque feed forward :1V

/

100

%

B

Model torque reference :1V

/

100

%

C

Model position deviation :0.05V

/

1 command unit

D

Estimated disturbance torque :1V

/

100

%

E

Anti-vibration monitor :1V

/

1000 min

-1

F

System constant setting data output

1

Analog monitor 1

magnification

0

1 time

0

1

10 times

2

100 times

3

1/10 times

4

1/100 times

2

Analog monitor 2

selection

0 - F

The same as the descriptions for "Analog monitor 1

selection"

0

3

Analogue monitor 2

magnification

0 - 4

The same as the descriptions for "Analog monitor 1

magnification"

0

MD3004

(Pn004)

Applied

function

selection

0

Optional board selection

0

Without optional board

0

1

With analogue speed reference input option

2

With linear scale option

1

Reserved

0 - 1

−

0

2

Command mode

0

Network

0

1

Optional speed reference input mode

2

Parking

3

Reserved

3

Reserved

0

−

0

MD3005

(Pn005)

Applied

function

selection

0

Brake control signal

selection

0

Does not control a brake at local path.

0

1

Controls a brake at local path.

1

Reserved

0

−

0

2

Reserved

0

−

0

3

Reserved

0

−

0

MD3006

(Pn006)

Applied

function

selection

0

Tandem selection

0

Does not select tandem configuration

0

1

Master

2

Slave

1

The other tandem-axis

number

0 - 7

Sets the other tandem axis

0

2

Full-close

0

Type 2 specification

0

1

Type 1 specification

3

Reserved

0

−

0

User

Constant

No.

Digit

Name

Setting

Description

Factory

default

setting

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...