2.2 Protecting against electric noise

2-9

2.2 Protecting against electric noise

2.2.1 Separation of cables

There are three types of cables used in the YS 840DI system: AC Power, DC power, and sig-

nal. These types of cables must be separated from each other as follows:

• Two cables are considered to be bundled with each other if they are less than 100 mm apart.

• An electromagnetic shield is a grounded iron plate separating a type of cables from another.

Type

Cable

Separation requirements

AC power (1)

AC power supply lines

(primary/secondary)

These cables must not be bundled with DC power

cables (2) or signal cables (3), or must be provided

with an electromagnetic shield.

Solenoids and relays must be provided with a surge

absorber or a diode.

Power cables to spindle and servo

motors

AC lines to solenoids, contactors, and

relays

DC power (2)

24 VDC power supply lines to CNC,

I/O, and power supply modules

These cables must not be bundled with AC power

cables (1), or must be provided with an electro-

magnetic shield.

These cables must be separated far enough from

signal cables (3). DC solenoids and DC relays

must be provided with a diode.

24 VDC I/O lines between I/O and

machine

24 VDC lines to solenoids and relays

Signal (3)

PROFIBUS-DP cables between CNC

and I/O module and between I/O

module and converter

These cables must not be bundled with AC power

cables (1), or must be provided with an electro-

magnetic shield.

These cables must be separated far enough from

DC power cables (2). Cables that need to be

shielded must always be shielded.

RS232C cables

Cables to manual pulse generator

Encoder cables between spindle

inverter and spindle motor

Encoder cables between servo unit

and servo motor

Cables to separately mounted PG

Battery cables

Other cables that need to be shielded

INFO

Summary of Contents for CNC Series

Page 1: ...Maintenance Manual Serviceman Handbook MANUAL No NCSIE SP02 19 Yaskawa Siemens CNC Series...

Page 26: ...Part 1 Hardware...

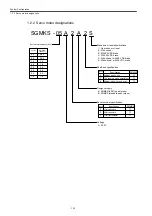

Page 38: ...System Configuration 1 2 3 Spindle motor designations 1 12...

Page 58: ...Installing the control panels 2 3 5 Installing lightning surge absorbers 2 20...

Page 62: ...Installing the motors 3 4...

Page 84: ...Connection method 4 3 2 Setting the rotary switches on the inverters and servo units 4 22...

Page 96: ...Part 2 Software...

Page 102: ...Software configuration 6 6...

Page 113: ...7 2 Network settings 7 11 8 Click on the radio button to the left of Specify an IP address...

Page 121: ...7 2 Network settings 7 19...

Page 122: ...Part 3 PLC...

Page 154: ...Part 4 Setting up and maintenance...

Page 160: ...Overview of System 10 1 2 Basic operation 10 6...

Page 204: ...How to use Digital Operation 12 2 9 Setting the password setting for write prohibit 12 32...

Page 327: ...Error and Troubleshooting 15 4...

Page 328: ...15 1 Errors without Alarm Display and Troubleshooting 15 5...

Page 329: ...Error and Troubleshooting 15 6...

Page 343: ...Maintenance and Check 16 3 3 Setting up Initializing Absolute encoder 16 14...