6-1

183574-1CD

183574-1CD

6

Alarms and Messages

6.1 Alarms Based on Barrier Door Operation

ArcWorld 50/50S/52/52S

6

Alarms and Messages

This section contains information on alarms that are generated by the

Controller. Cause and resolution of each alarm are presented to help with

troubleshooting. For additional help contact Customer Support.

6.1 Alarms Based on Barrier Door Operation

Many of the alarm text below are for Station 1 (ST1). These alarms may

also occur for Station 2, in that case the alarm text will show “ST2” instead

of “ST1”.

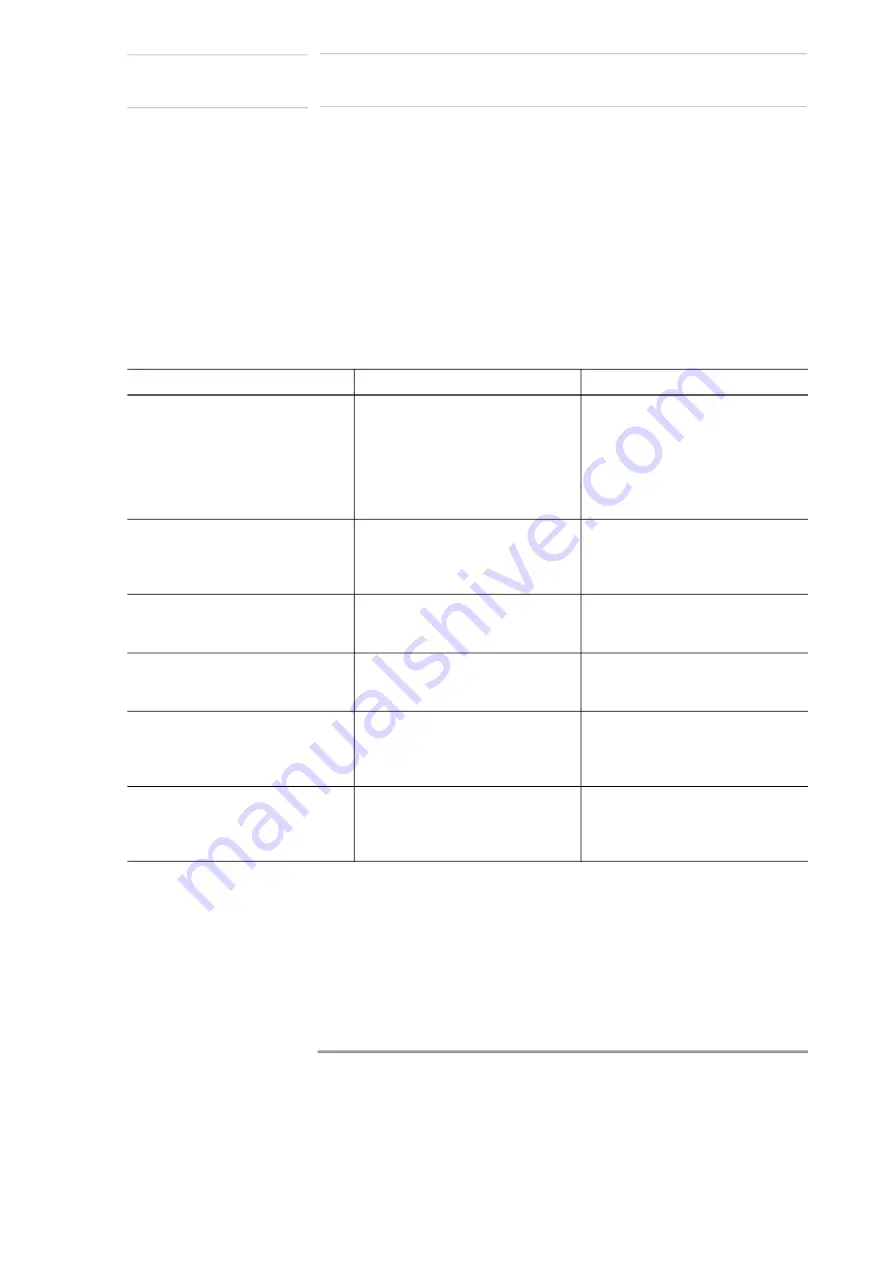

Table 6

-

1: Barrier Door Alarms

1)

Alarm Text

Alarm Cause

Suggested Resolutions

ST1 Barrier Fault Occurred

Some sort of alarm in the VFD

which provides motion to the door.

- Press corresponding general

output to reset the VFD.

Station 1 = OUT #2027

Station 2 = OUT #2059

Some alarms can only be cleared

by cycling power to the control

drive. These are not typical.

ST1 Door Overtime Flt

Door was moving longer than

4.0 seconds. The total door cycle

time is expected to be under

3.0 seconds.

Check for mechanical failure of the

door, or failures in Raised or Lower

switches.

ST1 Door Raised Not On

Door was moving up longer than

5 seconds and the “Door Raised”

switch never engaged.

Investigate Door Raised proximity

switch. Check for proper operation

in Manual mode. Verify cabling.

ST1 Door Raised Not Off

Door was moving down longer

than 5 seconds and the “Door

Raised” switch stayed on.

Investigate Door Raised proximity

switch. Check for proper operation

in Manual mode. Verify cabling.

ST1 Door Lowered Not On

Door was moving down longer

than 5 seconds and the “Door

Lowered” switch never engaged.

Investigate Door Lowered

proximity switch. Check for proper

operation in Manual mode. Verify

cabling.

ST1 Door Lowered Not Off

Door was moving up longer than

5 seconds and the “Door Lowered”

switch stayed on.

Investigate Door Lowered

proximity switch. Check for proper

operation in Manual mode. Verify

cabling.

1 Inputs to Reference:

· ST1 Door Lowered = IN #2019

· ST1 Door Raised = IN #2020

· ST1 Door Fault (VFD) = IN #2030

· ST2 Door Lowered = IN #2051

· ST2 Door Raised = IN #2052

· ST2 Door Fault (VFD) = IN #2062

89 of 126