5-1

183574-1CD

183574-1CD

5

Maintenance

ArcWorld 50/50S/52/52S

5

Maintenance

Maintenance must be performed by authorized personnel who are familiar

with the ArcWorld. Make sure to read and understand the documentation

for a particular component before doing repairs or maintenance. Make

sure to understand the maintenance procedures, have the proper tools at

hand, comply with all safety instructions and precautions given throughout

this manual and follow all local and federal regulations.

The maintenance intervals given in

are recommendations only.

Adjust the frequency and level to suit the specific equipment schedules

and shop environment.

For periodic maintenance procedures and schedules for the individual

components of the ArcWorld, refer to the documentation that is included

).

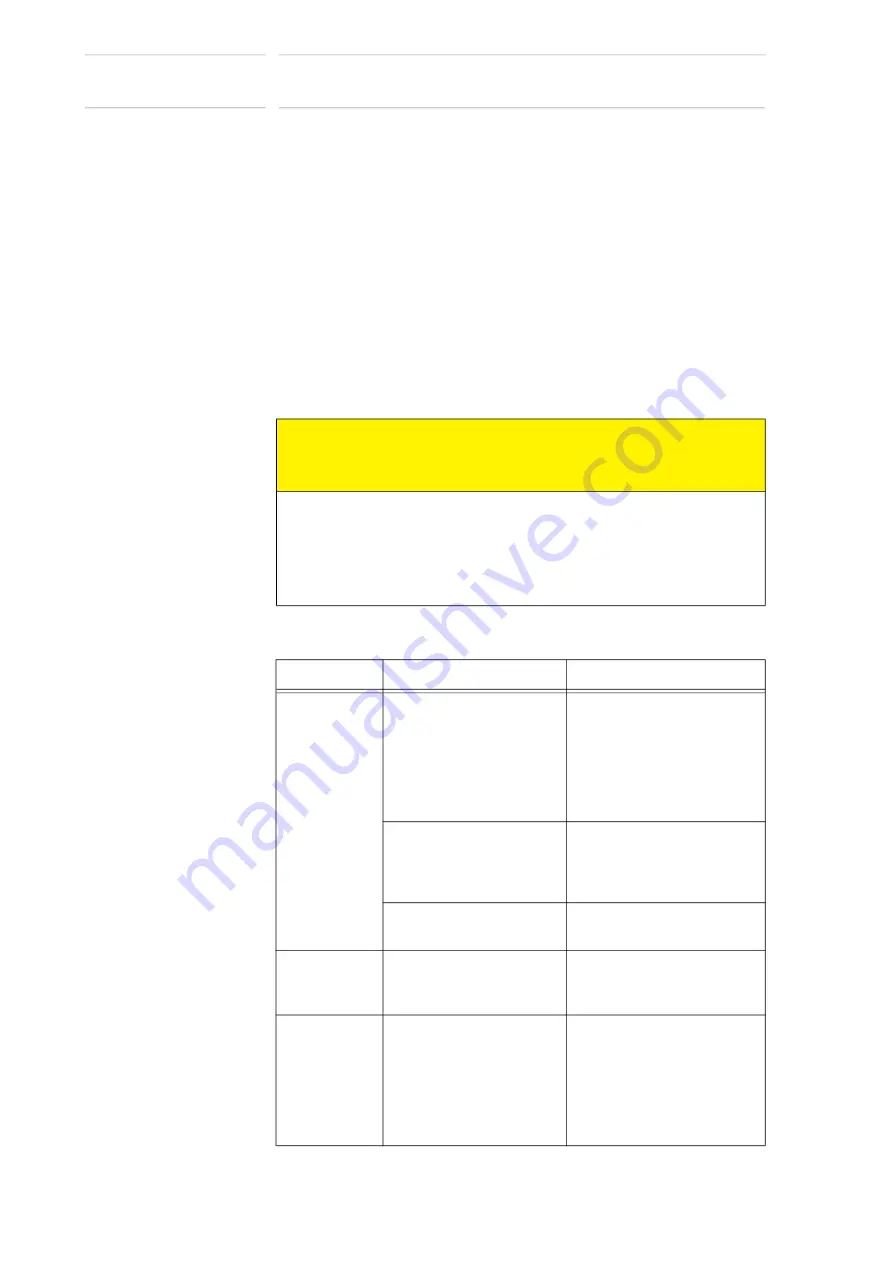

CAUTION

• Use only YASKAWA-specified antifreeze if the system uses a water-

cooled torch.

Do not use automotive antifreeze. It typically contains additives that can

clog the small cooling ports in the torch and damage sealing gaskets in

the water circulator pump.

Table 5

-

1: Periodic Maintenance

FREQUENCY

COMPONENT

PROCEDURE

Daily

Water Circulator (optional)

Check level of coolant/

antifreeze. If necessary, add a

mixture of YASKAWA coolant/

antifreeze and distilled water.

Mix antifreeze and distilled

water in proportions shown on

the antifreeze container.

All safety related items –

work-cell door interlocks,

EMERGENCY STOP

buttons, arc curtains, etc.

Check physical condition of

each safety item and ensure

that it is working correctly.

Gas and Water Hoses

Inspect hoses for damage and

replace as required.

Weekly

ArcWorld

Remove accumulated dirt,

grease, and debris from inside

and outside the work cell.

Every Six

Months

System Components

Common Equipment Base

(optional)

Check the integrity and

security of anchor hardware in

accordance with Hilti

®

documentation. Check the

torque of hold-down nuts in

accordance with Hilti

®

documentation.

88 of 126