344

YASKAWA ELECTRIC

SIEP C710617 19A YASKAWA AC Drive CR700 Technical Manual

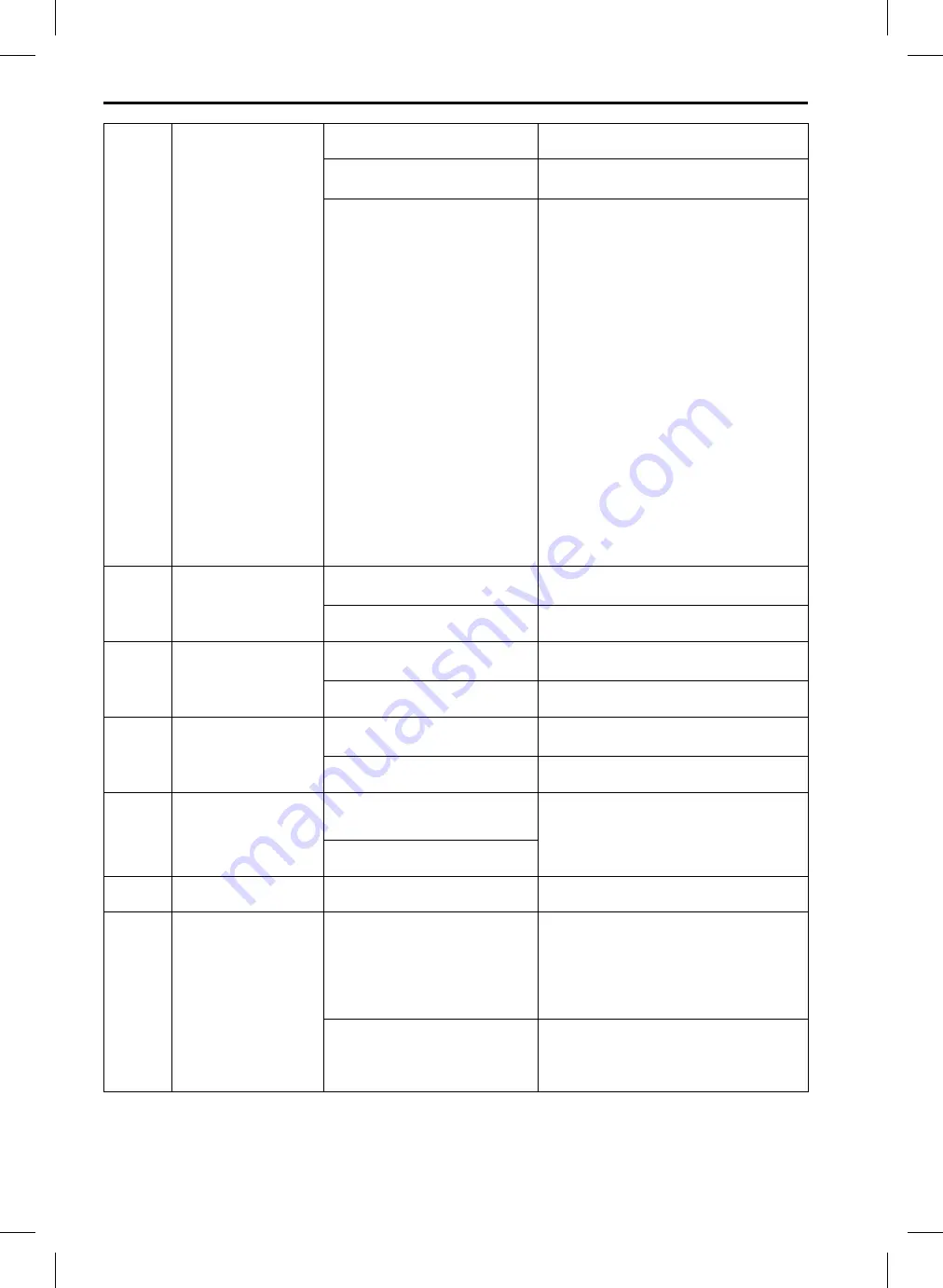

oH3

Motor Overheat (PTC

Input)

The thermistor wiring that detects motor

temperature is defective.

Correct wiring errors.

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the

fault.

The motor has overheated.

•

Examine the load level, acceleration/deceleration

times, and motor start/stop frequency (cycle

time).

•

Decrease the load.

•

Increase the values set in

C1-01 to C1-08

[Acceleration/Deceleration Time]

.

•

Set

E2-01 [Motor Rated Current (FLA)]

correctly to the value specified by the motor

nameplate.

•

Make sure that the motor cooling system is

operating correctly, and repair or replace it if it is

damaged.

•

Adjust

E1-xx [V/f Pattern Parameters]

settings.

Decrease the values set in

E1-08 [Mid Point A

Voltage]

and

E1-10 [Minimum Output Voltage]

.

For motor 2, adjust

E3-xx [V/f Pattern for Motor

2]

settings. Decrease the values set in

E3-08

[Motor 2 Mid Point A Voltage]

and

E3-10

[Motor 2 Minimum Output Voltage]

. For motor

3, adjust

E7-xx [V/f Pattern for Motor 3]

settings. Decrease the values set in

E7-08

[Motor 3 Mid Point A Voltage]

and

E7-10

[Motor 3 Minimum Output Voltage]

.

Note:

If

Ex-08

and

Ex-10

are set too low, the overload

tolerance will decrease at low speeds.

oL3

Overtorque 1

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the

fault.

The parameters are incorrect for the

load.

Adjust the overtorque detection parameters.

oL4

Overtorque 2

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the

fault.

The parameters are incorrect for the

load.

Adjust the overtorque detection parameters.

oL5

Overload Detection (oL5)

A fault occurred on the machine.

Example: Overload occurred.

Examine the machine and remove the cause of the

fault.

The parameters are incorrect for the

load.

Adjust the overload detection parameters.

oL6

Light-load Accel 2 Fault

(oL6)

The setting for hold level and fault

detection level of Light-load 2 functions

are not appropriate.

Output frequency >

S4-08 [Light-load 2

Activation Freq]

.

Adjust

S4-10 [L-L 2 Motoring Hold Level]

,

S4-12

[L-L 2 Regen Hold Level]

, and

S4-15 [L-L 2 Fault

Detection Level]

settings.

oS

Overspeed

Overshoot is occurring.

Decrease

C5-01 [ASR Proportional Gain 1]

and

increase

C5-02 [ASR Integral Time 1]

.

ov

DC Bus Overvoltage

There are surge voltages in the input

power supply.

Connect a DC reactor to the drive.

Note:

If you turn the phase advancing capacitors ON

and OFF and use thyristor converters in the

same power supply system, there can be surge

voltages that irregularly increase the input

voltage.

The drive output cable or motor is

shorted to ground. (The current short to

ground is charging the main circuit

capacitor of the drive through the power

supply.)

1. Examine the motor main circuit cable,

terminals, and motor terminal box, and then

remove ground faults.

2. Re-energize the drive.