5.13 Motor Overload Detection Level

5.13.2 Detection Timing for Overload Alarms (A.720)

5-40

5.13.2

Detection Timing for Overload Alarms (A.720)

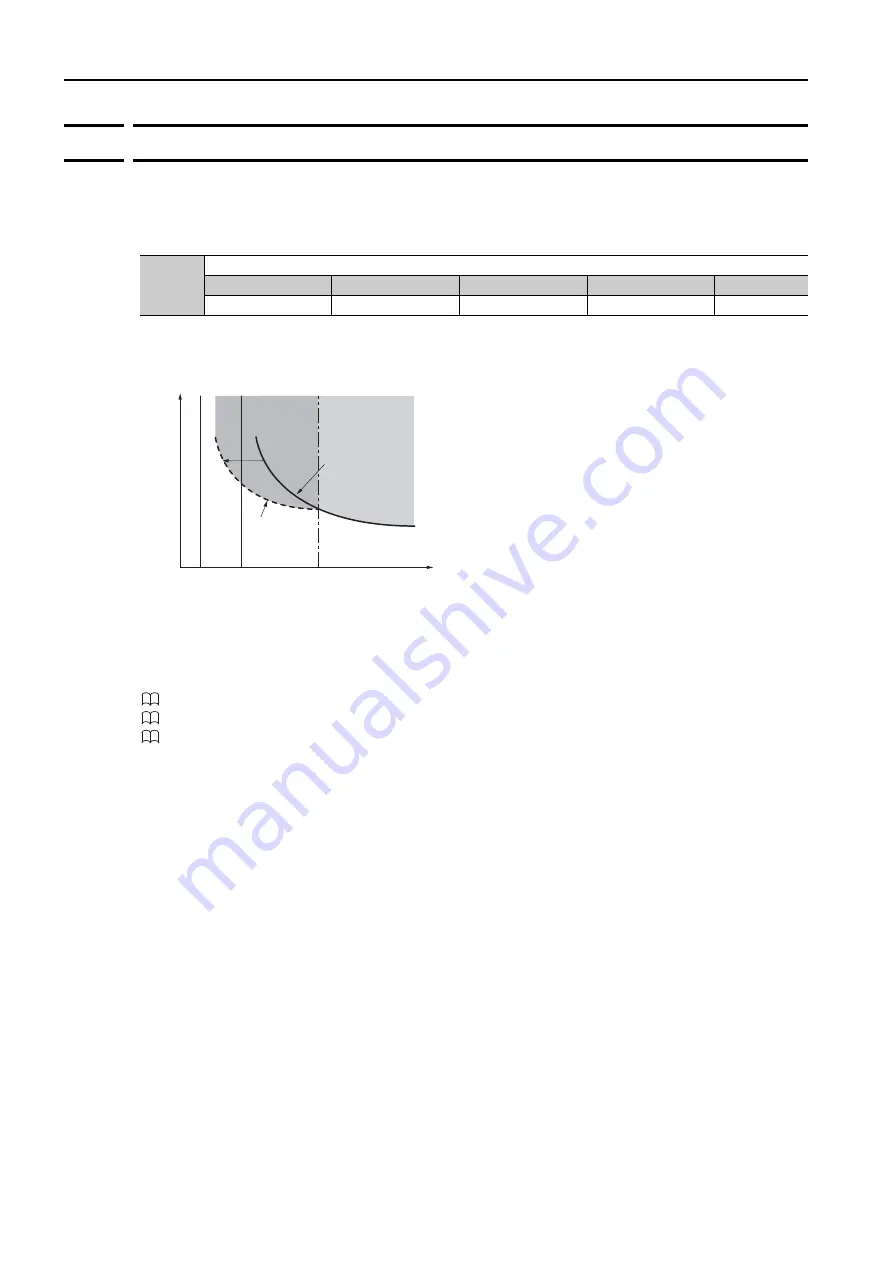

If Servomotor heat dissipation is insufficient (e.g., if the heat sink is too small), you can lower

the overload alarm detection level to help prevent overheating.

To reduce the overload alarm detection level, change the setting of Pn52C (Base Current Der-

ating at Motor Overload Detection).

An A.720 alarm (Continuous Overload) can be detected earlier to protect the Servomotor from

overloading.

Note: The gray areas in the above graph show where A.710 and A.720 alarms occur.

Refer to the relevant manual given below for a diagram that shows the relationships between

the Servomotor heat dissipation conditions (heat sink size, surrounding air temperature, and

derating). You can protect the Servomotor from overloads more effectively by setting this derat-

ing value in Pn52C.

Σ

-7-Series Rotary Servomotor Product Manual (Manual No.: SIEP S800001 36)

Σ

-7-Series Linear Servomotor Product Manual (Manual No.: SIEP S800001 37)

Σ

-7-Series Direct Drive Servomotor Product Manual (Manual No.: SIEP S800001 38)

Pn52C

Base Current Derating at Motor Overload Detection

Setting Range

Setting Unit

Default Setting

When Enabled

Classification

10 to 100

1%

100

After restart

Setup

Overload

detection time

50%

100%

A.720

A.710

200%

Detection curve

for overload

alarms when

Pn52C = 100%

(default setting)

Detection curve

for overload

alarms when

Pn52C = 50%

Torque reference (%)