Communications D - 3

Using Modbus Communication

Serial communication can be performed with Direct Digital Controllers (DDCs) or similar devices using the Modbus protocol.

Modbus Communication Configuration

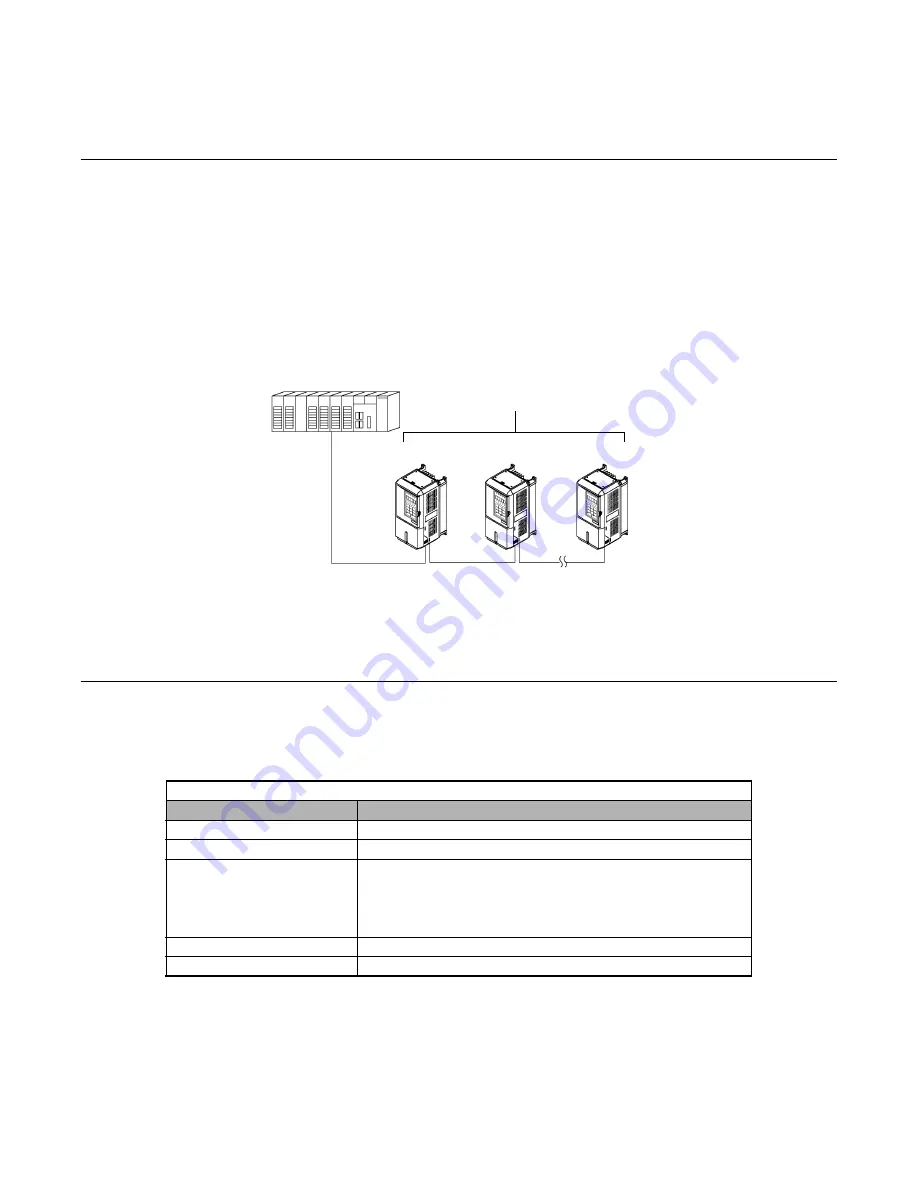

Modbus communication is configured using 1 master (PLC) and a maximum of 31 slaves. Serial communication between

master and slave is normally initiated by the master and responded to by the slaves.

The master performs serial communication with one slave at a time. Consequently, the slave address of each slave must be

initially set, so that the master can perform serial communication using that address. Slaves receiving commands from the

master perform the specified functions, and send a response back to the master.

Fig D. 1 Example of Connections between Master and Drive

Communication Specifications

The Modbus communication specifications are shown below:

Table D.1 Modbus Communication Specifications

Item

Specifications

Interface

RS-422, RS-485

Communications Cycle

Asynchronous (Start-stop synchronization)

Communications Parameters

Baud rate:

Select from 1200, 2400, 4800, 9600, and 19200 bps.

Data length:

8 bits fixed

Parity:

Select from even, odd, or none.

Stop bits:

1 bit selected

Communications Protocol

Modbus

Number of Connectable Units

31 units max.

Master

E7

E7

E7

Slaves

Summary of Contents for E7LBA002

Page 1: ...E7L Drive Bypass Technical Manual Model E7L Document Number TM E7L 01 ...

Page 8: ...Introduction vi Notes ...

Page 12: ...Table of Contents x Notes ...

Page 54: ...Electrical Installation 2 22 Wiring Diagram ...

Page 55: ...Electrical Installation 2 23 ...

Page 87: ...Start Up and Operation 4 9 Notes ...

Page 202: ...Diagnostic Troubleshooting 6 30 Notes ...

Page 248: ...Capacity Related Parameters B 6 Notes ...

Page 279: ...Communications D 27 Note ...

Page 280: ...Communications D 28 ...

Page 292: ...Spare Parts F 6 ...

Page 304: ...Index 12 ...

Page 305: ......