Maintenance and inspection

9 - 50

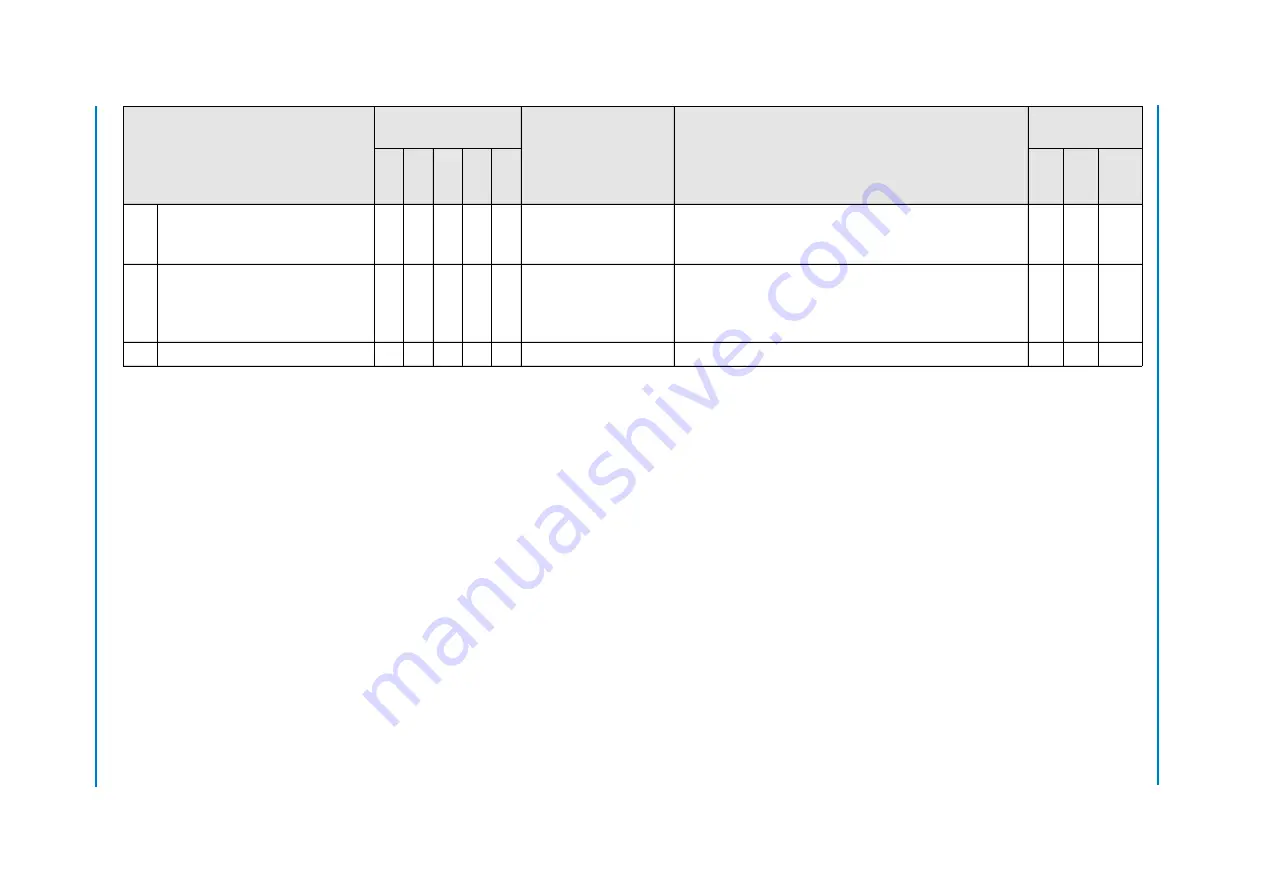

Tab. 9-1: Inspection intervals

11

Battery unit in robot

If a battery alarm appears or after the robot has

been operated for 24,000 hours, the battery must be

replaced.

12

S, L, U, R, axes gear

B- and T-axes pinion

Grease gun

Check for malfunctions (replace if necessary). The

grease

4

has to be replaced every 12000 hours (see

following chapters 9.7.1 "Grease filling the main ax-

es" and 9.7.2 "Grease filling the wrist axes").

13

Overhaul

1. The item numbers correspond to the following diagram "Inspection intervals"

2. When checking for conduction with multimeter, connect the battery to "BAT" and "OBT" of connectors on the motor side for each axis. Now remove the connectors of the encoders of the

respective motor. Failure to observe this sequence can lead to loss of home positions (see section 9.3 "Wrist unit" on page 56).

3. The internal wiring harness in the robot (for the S, L, U, R, B and T axes) must be replaced at the 24,000 hours inspection.

4. The grease and/or lubricants used can be found in the table "Inspection parts and grease used".

Item numbers

1

Schedule (h)

Method

Operation

To be per-

formed by:

Daily

1000

12000

24000

36000

1

2

3

Summary of Contents for GP25-12

Page 1: ...ROBOTICS YYR 1 06VXH25 A10 GP25 12 Standard Operating and Maintenance Manual...

Page 51: ...Maintenance and inspection 9 51 Fig 9 2 Inspection intervals...

Page 56: ...Maintenance and inspection 9 56 9 3 Wrist unit Sealing part U arm Cover Gasket U arm 1 2 3...

Page 77: ...Parts lists 11 77...