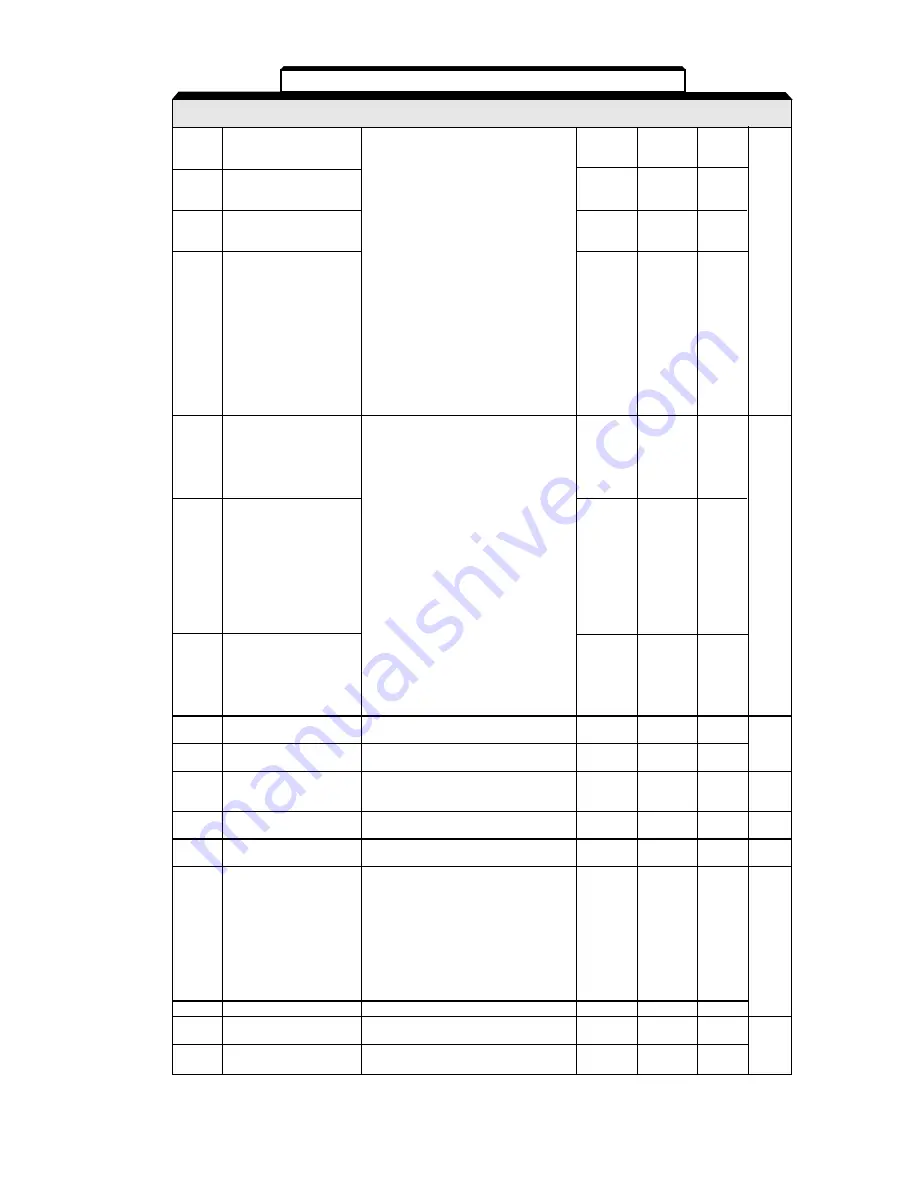

PARA-

SETTING RANGE

SETTING

FACTORY

USER

PARA.

METER

NAME

(AND UNITS)

INCREMENT

SETTING

SETTING

REF.

9:

Multi-step speed ref. cmd. D

n053

Multi-function Input

10: JOG Selection

1

5

Selection 4 (Terminal S4)

11: Accel/Decel time change cmd.

(5)

12: External Base Block (N.O.)

n054

Multi-function Input

13: External Base Block (N.C.)

1

6

Selection 5 (Terminal S5)

14: Speed search from max. freq.

(6)

Multi-function Input

15: Speed search from set freq.

n055

Selection 6 (Terminal S6)

16: Accel/Decel hold command

1

7

17: Remote/Local selection

(7)

18: Serial Communication / control ckt.

selection

19: Fast Stop - Fault (N.O.)

5.18

20: Fast Stop - Alarm (N.O.)

n056

Multi-function Input

21: Fast Stop - Fault (N.C.)

1

10

Selection 7 (Terminal S7)

22: Fast Stop - Alarm (N.C.)

(10)

23: PID control off

24: I value reset (PID)

25: I value hold (PID)

26: Over Heat Pre-alarm OH3

27: Accel/Decel Time Select 2

34: Up

0:

Fault

Multi-Function Output

1:

During running

n057

Selection 1

2:

Speed Agree

1

0

(Terminals MA, MB & MC)

3:

Zero Speed

4:

Frequency detection 1

5:

Frequency detection 2

6:

Overtorque detection (N.O.)

7:

Overtorque detection (N.C.)

8:

Undertorque Detection (N.O.)

Multi-Function Output

9:

Undertorque Detection (N.C.)

n058

Selection 2

10: Minor Fault

1

1

5.19

(Terminals P1 & PC)

11: During Base Block

12: Local / Remote

13: Ready

20: Frequency Reference Loss Detect (N.O.)

21: Overheat Pre-alarm OH3 (N.O.)

14: During auto restart

Multi-Function Output

15: During undervoltage

n059

Selection 3

16: During reverse run

1

2

(Terminals P2 & PC)

17: During speed search

18: Serial Comm. Controlled

``

19: PID feedback loss

n060

Analog Frequency Reference

0 to 255

1 (%)

100

Gain (term. FR to FC) note 4

5.8

n061

Analog Frequency Reference

-100 to 100

1 (%)

0

Bias (term. FR to FC) note 4

n062

Analog frequency reference

filter time constant

0.00 to 2.00

0.01 (sec)

0.10

(term. FR to FC) note 4

n064

Frequency Reference Loss

0:

No Detection

1

0

Detection

1:

Continue to run at 80% of max. frequency

n065

Monitor Output

0:

Analog monitor output

1

0

5.17

Selection

1:

Pulse monitor output

0:

Output frequency (10V = 100% Fmax)

1:

Output Current (10V = 250% drive

rated current)

2:

DC Bus Voltage

n066

Multi-function Analog Output

(10V = 400 VDC [800 VDC])

(Terminals AM & AC)

3:

Motor Torque

1

0

5.17

(10V = Motor rated torque)

4:

Output Power

(10V = Drive Capacity kW)

5:

Output Voltage 10V = n012 (voltage max)

6:

Frequency Reference

n067

Analog Monitor Gain note 4

0.00 to 2.00

0.01

1.00

n068

Analog Frequency Reference

-255 to 255

1%

100

Gain (CN2, Voltage Ref Input)

n069

Analog Frequency Reference

-100 to 100

1%

0

5.32

Bias (CN2, Voltage Ref Input)

A1-3

Table A1-1. Drive Parameters - Continued

Summary of Contents for GPD315/V7-4X

Page 1: ...GPD 315 V7 and V7 4X Technical Manual...

Page 4: ......

Page 20: ...xvi...

Page 22: ......

Page 40: ...1 18...

Page 52: ...3 2...

Page 56: ...4 4...

Page 101: ...5 45 PID Block Diagram...

Page 130: ...A1 8...

Page 134: ...A3 2...

Page 136: ...A4 2...

Page 146: ...A6 6...

Page 150: ...A7 4...

Page 154: ...A8 4...

Page 158: ......

Page 160: ......