Setting

Function

Page

61

External Speed Search

command 1

–

62

External Speed Search

command 2

–

63

Field weakening

–

65

KEB Ride-Thru 1 (N.C.)

–

66

KEB Ride-Thru 1 (N.O.)

–

67

Communications test mode

–

68

High Slip Braking (HSB)

–

6A

Drive enable

–

73

Low City Press

–

75

Up 2 command

–

76

Down 2 command

–

7A

KEB Ride-Thru 2 (N.C.)

–

7B

KEB Ride-Thru 2 (N.O.)

–

80

HAND Mode

–

81

HAND Mode 2

–

88

Volute-Thermostat Normally Open

Setting

Function

Page

89

Volute-Thermostat Normally Closed

8C

Disable Pre-Charge

–

8D

Multi Setpoint 1

–

8E

Multi Setpoint 2

–

8F

Low Water Level

–

90

High Water Level

–

92

Reset Accum

–

95

Remove Drive Disable

–

A8

Secondary PI Disable (N.O.)

–

A9

Secondary PI Disable (N.C.)

–

AA

Secondary PI Inverse Operation

–

AB

Secondary PI Integral Reset

–

AC

Secondary PI Integral Hold

–

AD

Select Secondary PI Parameters

–

AF

Emergency Override Forward Run

–

B0

Emergency Override Reverse Run

–

n

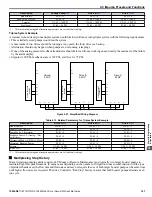

H2-01 to H2-03: Terminal M1-M2, M3-M4, and MD-ME-MF Function Selection

The drive has three multi-function output terminals.

lists the functions available for theses terminals using H2-01,

H2-02, and H2-03.

No.

Parameter Name

Setting Range

Default

H2-01

Terminal M1-M2 Function Selection (relay)

0 to 192

37: During Frequency Output

H2-02

Terminal M3-M4 Function Selection (relay)

0 to 192

F: Through Mode

H2-03

Terminal MD-ME-MF Function Selection (relay)

0 to 192

E: Fault

Table 4.21 Multi-Function Digital Output Terminal Settings

Setting

Function

Page

0

During run

–

1

Zero speed

–

2

Speed agree 1

–

3

User-set speed agree 1

–

4

Frequency detection 1

–

5

Frequency detection 2

–

6

Drive ready

–

7

DC bus undervoltage

–

8

During baseblock (N.O.)

–

9

Frequency reference source

–

A

Run command source

–

B

Torque detection 1 (N.O.)

–

C

Frequency reference loss

–

D

Braking resistor fault

–

E

Fault

–

F

Through mode

–

10

Minor fault

–

11

Fault reset command active

–

12

Timer output

–

13

Speed agree 2

–

14

User-set speed agree 2

–

15

Frequency detection 3

–

16

Frequency detection 4

–

Setting

Function

Page

17

Torque detection 1 (N.C.)

–

18

Torque detection 2 (N.O.)

19

Torque detection 2 (N.C.)

–

1A

During reverse

–

1B

During baseblock (N.C.)

–

1E

Restart enabled

–

1F

Motor overload alarm (oL1)

–

20

Drive overheat pre-alarm (oH)

–

22

Mechanical weakening detection

–

2F

Maintenance period

–

30

During torque limit

–

37

During frequency output

–

38

Drive enabled

–

39

Watt hour pulse output

–

3C

LOCAL/REMOTE status

–

3D

During speed search

–

3E

PID feedback low

–

3F

PID feedback high

–

4A

During KEB Ride-Thru

–

4C

During fast stop

–

4D

oH Pre-alarm time limit

–

4E

Braking transistor fault (rr)

–

4F

Braking resistor overheat (oH)

–

4.6 Basic iQpump Setup and Application Preset Parameters

YASKAWA

TOEP YAIP1W 01A YASKAWA AC Drive - iQpump1000 Quick Start Guide

159

4

Start-Up Programming & Operation

Summary of Contents for iQpump1000

Page 355: ......