E-6

Operation Precautions

• Select the I/O signal wires for external wiring to connect the product to

external devices based on the following criteria:

•

Mechanical strength

•

Noise interference

•

Wiring distance

•

Signal voltage

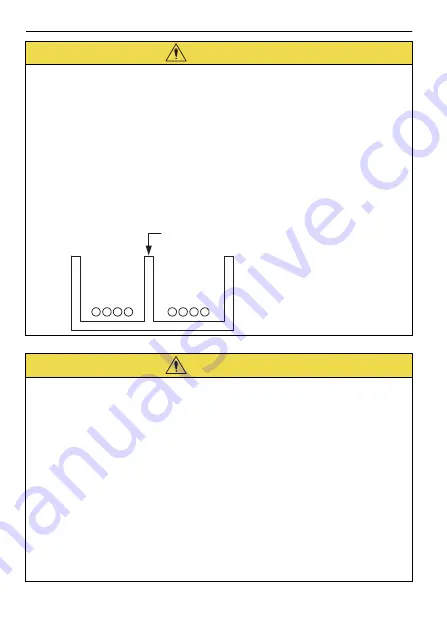

• Separate the I/O signal cables for control circuits from the power

cables both inside and outside the control panel to reduce the influ-

ence of noise from the power cables.

If the I/O signal lines and power lines are not separated properly, malfunc-

tion may occur.

CAUTION

• Follow the procedures and instructions in the user’s manuals for the

relevant products to perform normal operation and trial operation.

Operating mistakes while the Servomotor and machine are connected

may damage the machine or even cause accidents resulting in injury or

death.

• Implement interlock signals and other safety circuits external to the

product to ensure safety in the overall system even if the following

conditions occur.

•

Product failure or errors caused by external factors

•

Shutdown of operation due to product detection of an error in self-diag-

nosis and the subsequent turning OFF or holding of output signals

•

Holding of the ON or OFF status of outputs from the product due to fus-

ing or burning of output relays or damage to output transistors

•

Voltage drops from overloads or short-circuits in the 24-V output from

the product and the subsequent inability to output signals

•

Unexpected outputs due to errors in the power supply, I/O, or memory

that cannot be detected by the product through self-diagnosis

There is a risk of injury, device damage, or burning.

CAUTION

Example of Separated Cables

Power cable

I/O signal

cables in

control circuits

Steel separator