7 Utility Functions (Fn

)

7-30

7.16

Online Vibration Monitor (Fn207)

If vibration is generated during operation and this function is executed while the servo ON signal (/S-ON) is

still ON, the machine vibration can sometimes be suppressed by setting a notch filter or torque reference filter

for the vibration frequencies.

When online, vibration frequency caused by machine resonance will be detected and the frequency that has

the highest peak will be displayed on the panel operator. The effective torque reference filter or notch filter

frequency for the vibration frequencies will be automatically selected and the related parameters will be auto-

matically set.

In addition to this function, EasyFFT (Fn206) can be used to detect machine vibration and automatically make

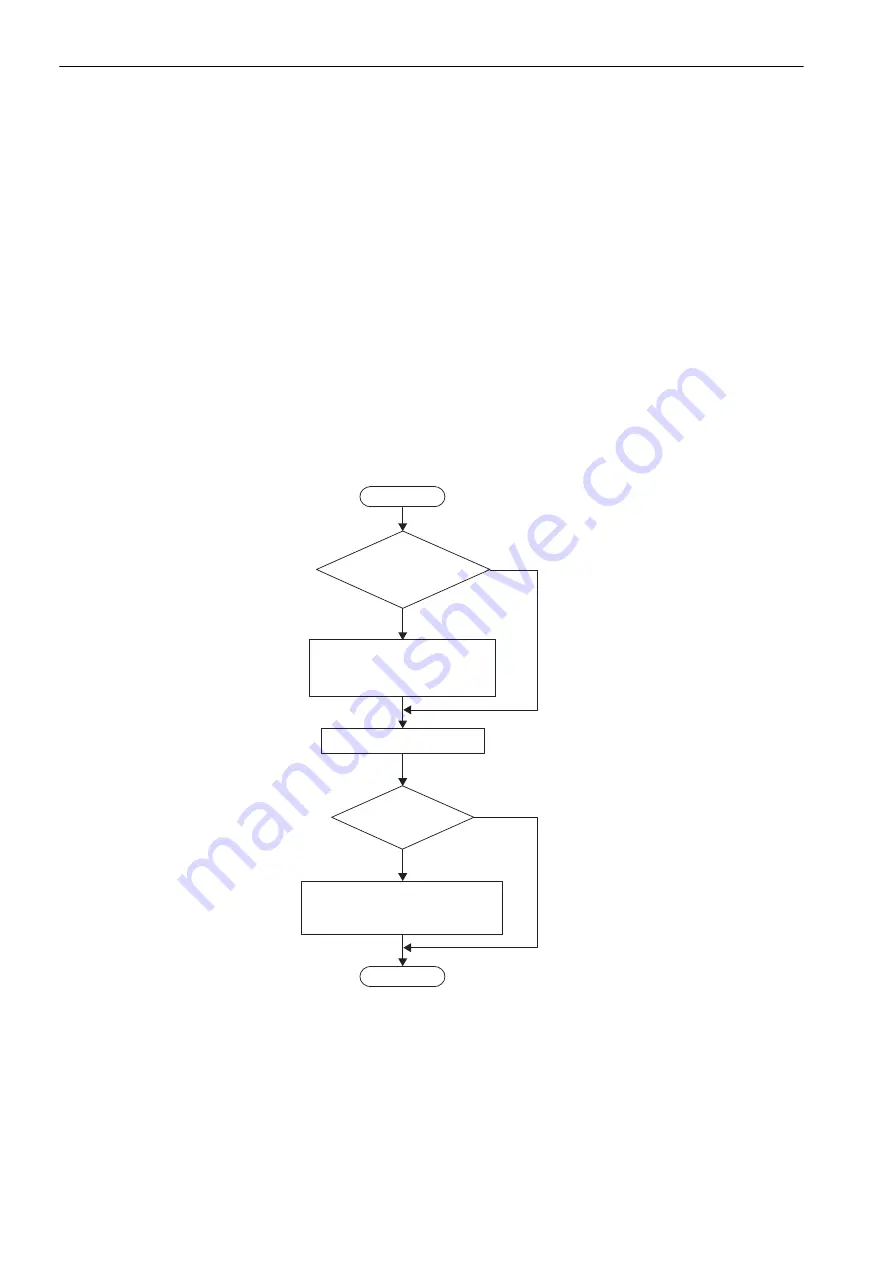

notch filter settings. Use the following flowchart to determine how these functions should be used.

If a multi-winding drive unit is used to make adjustments, it is recommended that you use advanced autotun-

ing. This built-in function is used to maintain interchangeability with previous models. There is normally no

need to use it.

(1) Preparation

The following conditions must be met to perform online vibration monitoring.

• The write prohibited setting parameter (Fn010) must be set to Write permitted (P.0000).

• The servo ON signal (/S-ON) must be ON.

• There must be no overtravel.

• The correct moment of inertia (Pn103) must be set.

Start

How to use EasyFFT (Fn206) and online vibration monitor (Fn207),

when they are mainly used for servo gain adjustment.

End

Vibration with

high-frequency noise

during operation

No

No

Yes

Yes

Adjust servo gain

Vibration

With the servomotor power ON,

execute online vibration

monitor (Fn207)

Turn OFF the servo ON signal (/

S-ON), and execute EasyFFT

(Fn206)